fuel cell membrane Articles

-

Thermodynamic modelling of a proton exchange membrane fuel cell

This paper presents the thermodynamic modelling of a proton exchange membrane (PEM) fuel cell at various operating conditions through energy and exergy analyses. In addition, the correlations and equations available in literature were used to determine thermodynamic irreversibilities in the PEM fuel cell at different operating conditions such as cell temperature, pressures of anode and cathode, ...

-

Engineering models for fuel cell production management

Membrane electrode assemblies are the key components of proton exchange membrane fuel cells. The future demand for this product could grow exponentially if key technical challenges are successfully addressed including low cost mass production and reliable customer order fulfilment. This study reports on a multidisciplinary team effort to formulate and apply engineering models for managing the ...

-

Effects of some micro-level exergetic parameters of a PEMFC on the environment and sustainability

This paper deals with studying the effects of some micro-level exergetic parameters of a Polymer Electrolyte Membrane Fuel Cell (PEMFC) on macro-level environmental pollution and sustainability. For this purpose, various exergetic, environmental and sustainability parameters of a PEMFC are investigated based on its operating and technical conditions. Consequently, these parameters may be utilised ...

-

Nanoporous Pt

n+–CeOxcatalyst films grown on carbon substratesDeposition of the Pt doped cerium oxide catalyst layers on carbon nanotubes and flat carbon substrates by magnetron sputtering leads to growth of solid solution films composed of nanorods oriented perpendicularly to the substrate surface forming fractal like highly porous structure. The films contain only cationic Pt2+ and Pt4+. Cerium oxide is partially reduced. The catalyst films reveal high ...

-

Corrosion and contact resistance measurements of different bipolar plate material for Polymer Electrolyte Membrane Fuel Cells

Different types of commercial stainless steels (SS316, SS310 and incoloy 800), poco graphite, composite graphite, titanium carbide, zirconium carbide and carbide base coating on aluminum substrate using thermal spray technique were evaluated as metallic bipolar plate in terms of Interfacial Contact Resistance (ICR) and corrosion resistance in a solution simulating the environment of a bipolar ...

-

Characterisation of two-phase flow and its impact on the performance of a Polymer Electrolyte Membrane fuel cell stack

Water management is one of the most critical issues for high-performance Polymer Electrolyte Membrane (PEM) fuel cells. A flow network model was developed to study the possibility of two-phase flow inception along the gas flow channels in the cathode side of a PEM fuel cell stack. The conventional Darcy-Weisbach equation and homogeneous flow model are used to estimate the pressure distributions ...

-

Effect of various micro-porous layer preparation methods on the performance of a proton exchange membrane fuel cell

Proton exchange membrane fuel cells (PEMFCs) have been widely studied and discussed in the field of energy owing to their high energy efficiency and low waste emissions. A PEMFC uses hydrogen gas as a fuel, and works by causing hydrogen ions to link up with oxygen, producing liquid water as its sole by-product. The design of a PEMFC's micro-porous layer (MPL) can not only enhance cell ...

-

Membrane Electrode Assembly (MEA) Activation Procedures

Why is an activation procedure or break-in necessary for a membrane electrode assembly (MEA)? A large reason for performing an activation procedure or break-in is to properly humidify the membrane portion of the MEA that was dried out during the hot press stage of the membrane electrode assembly(MEA) production. MEAs will not work well when they are not fully humidified (see article: Why is ...

-

A Finite Element Method analysis and optimisation of a polymer electrolyte membrane fuel cell with interdigitated flow field design

Interdigitated polymer electrolyte fuel cells are particularly attractive due to the enhanced transport rates and benefits with respect to electrode flooding. A 2D isothermal model is used to simulate the outlining processes that occur at the elemental fuel cell level. A Finite Element Method analysis is conducted to simulate the flow and current density fields for different gas channel ...

-

Sulfonated poly(ether ether ketone)-functionalised silica composite membranes for applications in proton exchange membrane fuel cells

Sulfonated Poly(ether ether ketone) (SPEEK) and its composites are explored as potential alternatives for Nafion in fuel cell applications. In this work, we investigate the effects of the silica functionalisation route on the thermal, mechanical and structural properties of SPEEK-Silica composite membranes. We compare two different methods – direct sulfonation and ...

-

Reviewing the factors affecting regenerative molten carbonate fuel cells

To evaluate the possibility to use molten carbonate fuel cell technology for high temperature electrolysis, the factors affecting the electrode reactions have been examined by surveying the published literature. The literature results showed that H2, CO2 and CO evolved as cathode off–gases and O2 as anode gas. At low polarisation, the discharge of oxide ions to O2 was the only anodic process; ...

-

In-situ investigation of the cathode catalysts for PEM fuel cells using differential electrochemical mass spectrometry

Differential electrochemical mass spectrometry (DEMS) involves applying a potential across an electrochemical cell and measuring the resulting current while concurrently analyzing gas products with a mass spectrometer. We used DEMS to investigate the mechanism of carbon support corrosion (CSC) in-situ at the cathode of proton exchange membrane fuel cell (PEMFC). The cathode exhaust gases were ...

-

Porous Titanium in Next-Generation Polymer-Electrolyte-Membrane Fuel Cells

Porous titanium has found a wide variety of unique and important applications including filtration, separation, catalyst supporting, gas absorbing, gas sparging, current collection, and medical implantation. Manufacture process for porous titanium Raw titanium powder preparation—Cold isostatic pressing or rolling—Sintering in high temperature & vacuum furnace-Machined to ...

-

Carbon Nanotubes and Nanohorn Hybrid Composite Buckypaper as Microporous Layer for Proton Exchange Membrane Fuel Cell

Abstract In the present work, carbon nanotubes (CNT) and CNT-carbon nanohorns (CNH) (0, 30, 50, 70 and 100 wt.% CNH) composite Buckypapers (BPs) were fabricated using vacuum filtration technique. Structure and property relation of composite BPs were studied using scanning electron microscope, four probe technique, BET surface area and contact angle measurements. Properties such as electrical ...

By SusChem

-

SnO 2 -Nafion ® nanocomposite polymer electrolytes for fuel cell applications

Fuel cells are capable to exploit the combustion of hydrogen to convert chemical energy into electricity. Polymer electrolyte fuel cells based on Nafion membranes are able to work in a relatively low temperature range (70–90ºC) but require operating relative humidity (RH) close to 100%. To develop proton-exchange membranes with adequate performances at low RH, an attractive strategy ...

-

Fuel cell–based distributed generation system with power flow and power quality control

This paper presents the modelling and control of fuel cell–based distributed generation system with embedded active filter functioning. It includes the modelling of proton electrolyte membrane fuel cell and the power conditioning unit interfacing the fuel cell to the utility grid with proper power flow control. The output of the fuel cell stack is given to the DC–DC boost converter ...

-

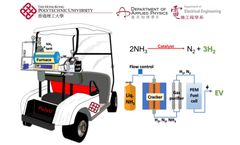

An Ammonia-powered Fuel Cell Electric Golf Cart System

Ammonia (NH3) is a carbon-free hydrogen (H2) carrier, which enables liquid-phase H2 storage and transport under mild conditions. Although the concept of NH3-to-H2 has been frequently proposed, the practical application of NH3 as the energy source for H2 power automotive systems is rarely reported. To close the gap between NH3 supply and H2 utilization, we demonstrated an NH3-powered fuel ...

-

South Africa`s fuel cell plan risks failure without support

An ambitious strategy to create fuel cell products for export will need incentives and cross-government backing to bear fruit, says Radhika Perrot. South Africa's Department of Science & Technology (DST) has been laboriously pushing for the development of hydrogen fuel-cell technology through an ambitious research and development (R&D) strategy since 2005. Fuel cells can convert the ...

By SciDev.Net

-

Ceramics 101: The QuantumScape Separator in Context

QuantumScape’s solid-state lithium-metal battery technology is enabled by our proprietary ceramic solid-electrolyte separator. While you may be familiar with everyday examples of ceramics, like a coffee mug, high-tech ceramics are likely less well-known. In this blog, we’ll review the basics of ceramics – what they are, how they’re made, how they’re used – and ...

By QuantumScape

-

Key Objectives in Modern Fuel Cell Studies

What are Fuel Cells? Fuel cells use the chemical energy of hydrogen or an alternative fuel to cleanly and efficiently produce electricity. Using hydrogen as the fuel only produces water, heat, and electricity. Hydrogen (the fuel) is supplied continuously, unlike in a battery, and a dynamic equilibrium is maintained. ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you