Refine by

Heat Exchanger Articles & Analysis

256 articles found

In the complex environment of nuclear power plants, safety and precision are non-negotiable. Regular and thorough inspections play a major role in ensuring safety and efficiency—but these are often high-risk procedures that involve examining high-radiation, hard-to-reach areas. Because of this, operators require technology that goes beyond traditional methods. In this discussion, we will ...

The coconut tree (Cocos nucifera) is one of the world’s most versatile and valuable plant species. Capable of producing food, fuel, cosmetics, building materials, growing media and cosmetic compounds, it’s no wonder that in the Philippines, the coconut is known as the Tree of Life. The global market for coconut products is predicted to reach $53.4 billion by 2033, thanks to annual ...

Thermal Management: Nitinol tubing is used in heat exchangers and cooling systems due to its ability to withstand high temperatures. ...

This zoned heating ensures that volatile components are efficiently cracked without over-carbonizing the residue. Integration with waste heat recovery units further enhances energy efficiency. Heat exchangers and regenerative burners are used to capture and reuse thermal energy from exhaust gases. In some configurations, the ...

This ensures uniform residence time and maximizes heat transfer from the external furnace or internal heat carrier to the feedstock. ...

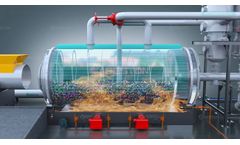

The first few months of 2025 have been among the most economically turbulent in recent history, but despite this there are still signs anaerobic digestion (AD) will continue to play a key role in boosting energy security, tackling climate change, and managing organic wastes. The global biogas market was estimated to be worth USD 65.53 billion in 2024 and is projected to expand 4.2% per year ...

Hydraulic power units (HPUs) are the backbone of countless industrial applications, providing the muscle needed to perform heavy-duty tasks with precision and efficiency. From construction sites to manufacturing plants, these systems play a critical role in powering machinery and equipment that would otherwise be impossible to operate. However, with so many options available, selecting the right ...

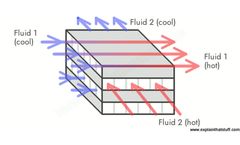

Chemical processes often require heat to be transferred between substances in ways that prevent thermal damage, promote chemical reactions, and maintain safety standards. Shell and tube heat exchangers (STHEs) are widely used in these applications, offering efficient heat transfer capabilities that are essential for processes ...

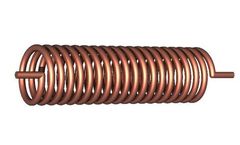

For example, the thermal conductivity of C11000 copper alloy is as high as 401 W/(m·K), which makes it excellent in applications such as radiators and heat exchangers that require efficient heat conduction. In addition, other data also show that the thermal conductivity of high-purity copper is usually between 393 W/m°C and 401 ...

Cooling water circuits and solar systems are often filled with water-glycol mixtures for frost protection reasons. Propylene glycol added to the water mainly serves as frost protection. The propylene glycol also provides a certain degree of corrosion protection. Due to the addition of propylene glycol, the viscosity of the circulation fluid used increases slightly and the air separation capacity ...

The heat input is a driving factor for the breakdown of complex organic molecules into simpler compounds. ...

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. ...

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar ...

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar ...

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

Recently, varelen design and developed mine flameproof dry transformer with active heating pipe, the company's full wave mine flameproof dry transformer products were upgraded again, creating a new era of flameproof heat dissipation. ...

High-Temperature Design Transformer are built to handle high temperatures according to IEC 60076 standards. They utilize water to fluid heat exchangers and high-temperature insulation materials. By using ester as an insulation fluid, these transformers can operate at higher temperatures than those using mineral oils. ...

Refractory Lining: Check the condition of the refractory lining inside the reactor. Cracks or erosion can lead to heat loss and structural damage. Seals and Gaskets: Examine all seals and gaskets for wear. ...

District heating—the generation of heat in a central location and distribution of it to local residences, businesses, and industry at greater economies of scale than individual heating systems—plays an important role in helping the transition to clean energy in the fight against climate change. The challenge, however, is that district heating, used to provide hot water and heat within ...