Refine by

Predictive Maintenance Articles & Analysis

39 articles found

These smart control systems are vital for maintaining consistent operational parameters, minimizing thermal fluctuations, and achieving high energy conversion efficiency. They also enable predictive maintenance by monitoring temperature differentials and system anomalies. ...

Artificial Intelligence in BMS: Machine learning algorithms deliver predictive maintenance, optimizing charge protocols to extend cell life. ...

Case Example: Predictive Maintenance in a Steel MillIn a steel manufacturing facility, a 40-ton overhead crane operates continuously across three shifts. ...

The right connection strategy can maximize energy transfer, simplify maintenance, and prolong battery life—while the wrong choice risks voltage drop, overheating, and even catastrophic failure. ...

We’ll also introduce RICHYE, a lithium battery specialist whose advanced solutions power forward-thinking material handling fleets. 1. From Reactive Maintenance to Predictive Insights Lead-Acid’s Maintenance Burden Maintaining lead-acid forklift batteries demands daily watering, periodic equalization charges, and the constant ...

What is Predictive Maintenance? Predictive maintenance refers to the use of data analysis and advanced monitoring technologies to predict when equipment parts or systems might fail. ...

Diagnostic Features to Prevent Malfunctions Modern concrete trailer pumps are equipped with self-diagnostic capabilities, allowing for early fault detection and predictive maintenance. The electric control system logs operational anomalies and alerts operators about potential failures before they escalate. ...

Introduction Syngas, or synthesis gas, is a vital component in various industrial processes, serving as a fuel source and a raw material for chemical synthesis. It is primarily used in power generation, chemical production, and fuel manufacturing. Accurate measurement of syngas is critical to ensuring efficiency, safety, and compliance with industry standards. This article explores the ...

Activities: Develop a proactive maintenance schedule using equipment history and performance data. Employ preventive maintenance techniques like condition monitoring and predictive maintenance. 4. ...

Training Programs: Educating operators on machine operation, maintenance, and troubleshooting. Maintenance and Spare Parts Reliable after-sales service, including maintenance and spare parts availability, is essential for the sustained operation of biochar machines. Key considerations include: Regular Maintenance Programs: ...

Cost Savings: Implementing ESA as part of a predictive maintenance strategy can lead to cost savings by reducing the need for emergency repairs, extending equipment lifespan, and optimizing maintenance schedules based on actual asset condition. Continuous Improvement: Historical data analysis drives continuous improvement in ...

The following will discuss some possible extended functionalities and their potential impacts. 1. Predictive maintenance and fault warnings Traditional electrical meters primarily focus on the measurement and recording of electricity, while future smart energy meters may integrate more sensors and data analysis functions to achieve predictive ...

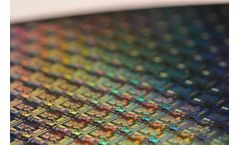

The semiconductor fabrication industry, which is vital to the modern digital era, hinges significantly on the precision and purity of gasses used in its manufacturing processes. Ultra high purity gas mixing plays a pivotal role in ensuring the quality and performance of semiconductors. This article delves into the intricacies of ultra high purity gas mixing. It explores its importance, ...

Predictive maintenance requires monitoring The demand for electrolysers is growing by leaps and bounds. ...

Semiconductors are the fundamental components of modern electronic goods. Cleanliness is crucial inside of a semiconductor fabrication facility, considering the scale of the working surfaces (nanometers). Contaminants of all types can result in defects, leading manufacturers to implement extremely strict and precise production control procedures with high reproducibility, especially during one ...

Carrying out a predictive maintenance plan is a smart way to avoid future costs, you know that. And in order to do this, you will need predictive maintenance software and a plan. But what are the most common mistakes made in a maintenance programme of this type? ...

Industrial facilities and manufacturers are especially keen to use predictive analytics to monitor heat and cooling equipment performance: they can automatically alert malfunctions, prevent errors or notify when it is time for maintenance. ...

This supports condition-based predictive maintenance and asset management. The system continuously monitors partial discharges and tracks temperatures to detect potential insulation or connection risks. ...

Artificial Intelligence and machine learning can assist discoms to manage consumer grievances, theft and pilferage detection, predictive and preventive maintenance. Novel technologies such as peer-to-peer blockchain trading can make RE more accessible, concurrently providing a host of other benefits such as grid balancing and the provision of ancillary services. ...

But they are all doing so in the knowledge that no digitisation strategy can turn its back on data analytics.For example, by treating data in the right way, it is possible to create detailed reports on everything that happens in a factory or to establish Artificial Intelligence (AI) algorithms capable of reacting in real time to unforeseen production events and even predicting ...