waste pyrolysis Articles

-

The best way to Reduce Pyrolysis Plant Costs

If you're worried about pyrolysis plant costs, and you're trying to find the best strategies to reduce your spending, there are numerous of options available. These are a couple of things you can do to lessen your upfront costs in addition to your expenses over time. Find a Vendor With Affordable Rates You'll want to be sure that you're capable of getting the waste pyrolysis plant you need for ...

-

Pioneering Sustainability: Pyrolysis Plants in the UK

In the realm of sustainable solutions, pyrolysis plants in the UK emerge as a pioneering force, embodying the fusion of innovation and environmental stewardship. These cutting-edge facilities harness the power of pyrolysis—a chemical decomposition process—to transform waste materials into valuable resources, all while mitigating the ecological footprint. The Rise of Pyrolysis At the ...

-

Read On to Find Out Why You Ought To Purchase a Pyrolysis Machine

It is not really required to incinerate manufacturing waste. It is recommended to work with a pyrolysis machine to transform them into useful products. It really is safe to use a pyrolysis plant mainly because it does not release harmful byproducts. Additionally it is profitable try using a pyrolysis machine to transform waste materials into useful products Please Read On to Find Out Why You ...

-

Recycling Tires having a Pyrolysis Plant

Numerous tires get worn out per week. The better people drive cars and also other vehicles around the world, the greater number of tires will break down and need to be discarded. Where do these kinds of products go? Unfortunately, many of them once ended up in landfills. Landfills are obtaining increasingly more full. More information on pyrolysis machine here. Today, there exists a promising ...

-

How You Can Locate The Best Continuos Type Pyrolysis Plant

Are you looking for a continuous pyrolysis plant? This can be something you will find quickly. They are popular today, more than ever before before, because of how they are able to convert different kinds of material into burnable fuel. Recycling is a prominent focus of numerous businesses, primarily because they can help to save a ton of money. Additionally, they are able to produce their very ...

-

Where To Locate A Pyrolysis Machine For Sale

Waste recycling is a very lucrative business. Dependant upon the area you live in, you just might find excellent possibilities to turn waste into useful products to sell to people inside your local community. If, as an example, you think about investing in a tire pyrolysis machine for sale, you should start by assessing the possibility of this particular business. Assembling a business plan is ...

-

Why You Should Consider Purchasing A Pyrolysis Plant

What are you doing together with the waste materials that you simply produce? If you're currently sending these materials to a landfill, you really should take a close look at some of your additional options. Purchasing a waste pyrolysis plant could permit you to start using these materials inside a far better way. It Could Process Many Feedstocks One of the best reasons to purchase pyrolysis ...

-

The Way To Obtain An Affordable Pyrolysis Oil Plant?

The conversion of material like organic material, plastic, as well as rubber, can be something more people are doing today than ever before. What they are converting it into his burnable fuel, along with natural oil, that could are derived from many of these waste matter. Recycling has developed into a prominent feature within our society, no matter what country you live in. You can find huge ...

-

Huayin waste tyre to oil pyrolysis plant in Bangladesh - Case Study

Huayin waste tyre to oil pyrolysis plant in Bangladesh successfully installed in November 2018. Here are the delivery and installation pictures for your reference. This client processes waste tyres and get fuel oil in the end. ...

-

The Benefits Of The Continuous Pyrolysis Plant

The continuous pyrolysis plant is an excellent investment with your business. This plant permits you to get a lot of work done quickly and it doesn't take a long time to discover ways to operate the plant because the manufacturer is going to help you obtain started. This waste pyrolysis plant will burn biomass or rubber 24 hours a day. You should use the biomass to help make oil or charcoal your ...

-

Tyre recycling pyrolysis plant

To solve the problem of used tyres waste plastic and waste rubber in a green way, instead of landfill or burning. Waste tyre recycling pyrolysis plant is feeding in every second and minute,automatic ejecting wastes residue,fuel product day and night.waste tyre or waste plastic into fuel and energy .The raw material of tyre recycling pyrolysis plant is waste tyre ,waste plastics,waste rubber . ...

-

Pyrolysis

Introduction: Pyrolysis is formally defined as chemical decomposition induced in organic materials by heat in the absence of oxygen. In practice, it is not possible to achieve a completely oxygen-free atmosphere; actual pyrolytic systems are operated with less than stoichiometric quantities of oxygen. Because some oxygen will be present in any pyrolytic system, nominal oxidation will occur. If ...

-

The Cost Of A Pyrolysis Plant For Recycling Used Tires

If you are searching for many modern machinery that may recover valuable commodities from used tires, a pyrolysis plant is what you need. Such a plant can make many rubber-based waste matter into tradable end products. Furthermore, the conversion process does not involve the emission of any toxic fumes into the air. So, should you be looking for a zero-pollution, environmentally-friendly tire ...

-

Mini Pyrolysis Machine: Eco-Friendly Waste Solution

Welcome to our article on the Mini Pyrolysis Machine, an innovative and eco-friendly solution for waste management. This compact device is revolutionizing the way we address waste and transforming it into valuable energy. With its advanced pyrolysis technology, the Mini Pyrolysis Machine offers numerous benefits, from reducing landfill waste to generating income from recyclable materials. By ...

-

Recovered Resources from Waste: The Benefits of Oil Sludge Pyrolysis Systems

Recovered Resources from Waste: The Benefits of Oil Sludge Pyrolysis Systems The Problem: Traditional Waste Disposal and its Impact Our current waste management practices are unsustainable. Landfills overflow, polluting the environment and harming ecosystems. A significant portion of this waste contains valuable resources that could be recovered. The Solution: Pyrolysis Plants and Recovering ...

-

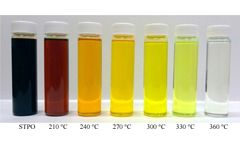

Environmental Impacts of Pyrolysis Oil Production and Utilization

In the quest for sustainable energy sources and waste reduction, pyrolysis oil has emerged as a promising player. This remarkable substance is obtained through the process of pyrolysis, which converts organic materials into a valuable liquid fuel. While it offers a plethora of benefits, it's crucial to scrutinize the environmental impacts of both its production and utilization. The Eco-Friendly ...

-

Just How Much Does a Pyrolysis Plant Cost?

When starting a waste plastic pyrolysis business, the fee for the pyrolysis machines is truly the initial thing you should consider. The reason being it's by far the most financially demanding part of the project. More so, it will be the core in the business and determines how successful a business venture will be. Furthermore, there are more factors that should be considered inside a large-scale ...

-

Functioning Procedure For The Continuous Pyrolysis Plant Along With The Advantages It Provides

The words ‘pyrolysis’ suggests the concurrent chemical and physical changes in the organic matter, that happen to be put through extremely high temperatures. A continuous waste tire plant can be a unique tire recycling machine which uses the pyrolysis process as a way to recycle discarded tires into oil and carbon. The benefit of these machines is simply because they can certainly make fuel oil ...

-

Machines From Pyrolysis Plant Manufacturers To Turn Tyre Waste Into Cash

The disposal of waste has turned out to be a tremendous problem for cities and towns in just about every country on planet earth. In the end, when materials are brought to seafills or landfills, they can take hundreds of years to decompose and during the decomposing period, they release harmful toxins to the atmosphere, ground, and oceans. Purchase this pyrolysis plant for sale to recycle tyre ...

-

What things to Consider When thinking about a Pyrolysis Plant available for purchase

Pyrolysis technology is green and has the possibility to be extremely profitable. The chance of profit will probably be higher once you select the best machinery to buy. These are among the factors which should be taken into consideration when you're seeking to choose a pyrolysis plant available for purchase. What sort of Waste Materials Is the Machinery Designed to Work With? Pyrolysis machinery ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you