Biodiesel Producer (Biodiesel Production) Equipment

-

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

The original cold flow additive for biodiesel.Broad spectrum formulation - effective for biodiesel produced from the widest range of ...

-

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

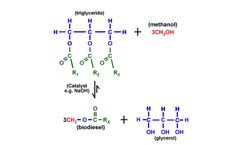

Biodiesel is produced via the transesterification of fats as shown by the chemical reaction to the left. There are some excellent publications relating to Biodiesel production. At Biofuel Systems we have been most impressed with the comprehensive Biodiesel Handbook and have made this available on our online ...

-

Manufactured by SPXFLOWbased in UNITED KINGDOM

The Automatic de-aerator for diesel and liquid biodiesel. The Tigerloop Auto 2 is designed to be compatible not only with diesel produced according to EN 590, but also biodiesel produced according to EN 14214 and HVO diesel (EN15940). The Tigerloop Auto 2 models are also designed to meet new demands on energy savings, ...

-

Manufactured by Bio Energy Shanghai Co., Ltd (BioGTS)based in CHINA

BioGTS Biodiesel biodiesel process produces renewable biodiesel. A wide selection of production materials: for example, waste biomass oil and grease from food processing plants, restaurants and municipal solid waste, oily parts separated from biological waste, wastewater, sewage sludge, and animal and fish processing and ...

-

Manufactured by Ceimici Novelbased in IRELAND

SmartCat™ delivers fast and complete transesterification as part of a continuous production process. Stage 1 at 60-62°C with 0.5% SmartCat™ for 2 hours producing 90% biodiesel and methanol. Stage 2 at 60-62°C with 35% SmartCat™ yields 100% biodiesel with trace catalyst and ...

-

Manufactured by World Energybased in CANADA

Traditional biodiesel production processes typically utilize feedstocks with Free Fatty Acid (“FFA”) content less than 1% because the presence of FFAs during the transesterification process will produce soaps and emulsions, which prevents the separation of methyl esters from glycerine. For this reason, traditional processes ...

-

based in INDIA

Arslan Enginery is having the complete process and technology of advanced (ATFE) process to produce biodiesel from all kind of crude vegetable oil. The biodiesel plant design are simple as the main equipment involved in it are filmed evaporators and distillation column. The one more option in plant biodiesel are to get an ...

-

Manufactured by Incbiobased in PORTUGAL

When producing Biodiesel from waste products, we cannot always guarantee that the end product will meet the EN14214 specification using our standard equipment. This is not because of our process, it is simply a reality with some low quality feedstock. ...

-

Manufactured by Scherzinger Pumps GmbH & Co.KGbased in GERMANY

Heating units must start safely at all times so that they can guarantee maximal passenger comfort and optimal pre-heating of the engine. Critical in this: consistently high-quality combustion during the lifespan of the pump and an equally precise suction performance (even in critical installation types). SCHERZINGER understands what is important in burner pumps and offers you quality products ...

-

Manufactured by Vmetsbased in CHINA

VMETS proprietary hydrodynamic cavitation technology, generates controlled hydrodynamic cavitation to produce biodiesel from vegetable oils, animal fats and biodiesel from waste cooking oil. Biodiesel refers to fatty acid methyl or ethyl esters formed by ester conversion of vegetable oil (such as rapeseed oil, soybean oil, ...

-

based in INDIA

Biodiesel is an alternative green fuel made from renewable resources like vegetable oil, animal fats etc. It is an eco-friendly fuel that helps in reducing the carbon footprint. ...

-

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

Unlike mineral diesel, biodiesel is perishable and starts to oxidise as soon as it has been produced. It reacts with atmospheric oxygen to produce volatile compounds, corrosive carboxylic acids and polymerized / cross-linked biodiesel gums that can damage diesel engine components. Already certain fuel pump manufacturers have ...

-

by IUCTbased in SPAIN

S50 is a bioester derived from natural oils which is compatible with diesel / FAME blends. S50 is structurally similar to FAME. It is composed of natural free fatty acids identical to the ones found in FAME. The only chemical difference is that S50 contains a glycerol monoalcohol instead of ...

-

Manufactured by Henan Barui Environmental Protection Equipment Co..Ltd.based in CHINA

Estenfication & Trans-esterification unit, is used to generate fatty acid methyl ester (biodiesel) from used vegetable oil (raw mateiral oil). The unit developed by us, consits of 2 types: reactor (see IMG 1) or reacting tower (see IMG 2). Besides, there is our own developed organic acid esterification process, that is the most advanced ...

-

Manufactured by Cavitation Technologies, Inc.based in USA

. This is beneficial, particularly in the case of phase transfer-catalysed reactions or biphasic systems. A major competitive advantage is our patented multistage cavitation reactors which we use for transesterfication process in production of biodiesel. ...

-

Manufactured by Maritime BioFuels (Foxcreek Consulting Services)based in CANADA

Biodiesel is an environmentally friendly, renewable fuel produced by the esterification of fats and oils with a primary alcohol. The fats and oils are derived from both animal and plant sources. This process allows for the thicker glycerin portion of these fats and oils to removed. The remaining biodiesel is much less viscous and can be ...

-

Manufactured by GlobeCore GmbH - Biodiesel Divisionbased in GERMANY

Previously cleared oil is supplied on heater line; there it is warmed up to operate temperature. The warmed-up oil moves to biodiesel reactor for biodiesel production. Also solutions of alkali and methanol are supply to the same reactor. At the exit from the biodiesel reactor by hydrodynamic mixing way and reaction of oil, solution of ...

-

Manufactured by Suomen Biovoima Oybased in FINLAND

Biodiesel is environmentally-friendly and renewable fuel that can be produced from waste greases and oils from municipalities, restaurants and ...

-

Manufactured by Vmetsbased in CHINA

The use of renewable energy helps a society with high energy demand, the problems of depletion of stocks that are causing fossil fuels, avoiding also the large amount of pollution generated oil wells and ...

-

Manufactured by CT Systemsbased in UKRAINE

Unlike companies which manufacture biodiesel production equipment (biodiesel processor) based on outdated, tank technologies, which have been used for over a century, our company uses the high-frequency magnetic impulse cavitation principle, previously used in classified technologies, allowing us to achieve some significant advantages: Low ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you