Biomass Drying Equipment For Bioenergy

-

Manufactured by Jiangsu Jingliang New Energy Co.,Ltdbased in CHINA

We can provide professional pellets making solutions according to customer’s actual needs.Wood pellet line capacity ranges from 1T to 20T per ...

-

Manufactured by Anyang General International Co., Ltd (AGICO)based in CHINA

The reason why we need biomass dryer system is because we have to consider the impact of raw material moisture on the biomass pellet machine. Biomass pellet mill in the production of pellet making process, the use of raw materials contained in the water, can better help the particles forming. But the humidity is best kept at 10-15%. If the raw material moisture content is too high, we need to use ...

-

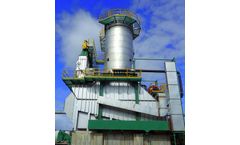

Manufactured by AWILA Anlagenbau GmbHbased in GERMANY

Drying of biomass for energy use is becoming increasingly important. Precise control of the drying process is essential to ensure that drying remains cost-effective. The AWILA directly heated drum drier is extremely efficient and robust. It can be heated in many ways, including waste heat which does not incur any cost. The hot drying air flows through the product and heats it, absorbing the ...

-

Manufactured by Allance Pellet Machinerybased in CHINA

Charcoal briquette machine can press bamboo, wood, shells, straw (besides rice and wheat straw) and other waste into various shapes solid briquettes with center hole without adding any binders. After the raw material being crushed and dried, they will be formed into biomass briquette under high pressure and temperature by our charcoal briquette machine.The color of the finished products is black ...

-

Manufactured by SAIREMbased in FRANCE

SAIREM’s GLP range of microwave generators provide continuous wave (CW) output power adjustable from 5 to 18 kW or 5 to 36 ...

-

Manufactured by Wright Tech Systems Inc.based in CANADA

Biomass is a renewable energy resource and is often defined as "the biodegradable fraction of products, waste and residues from agriculture (including vegetal and animal substances), forestry and related industries, as well as the biodegradable fraction of industrial and municipal waste" (source EU Directive 2001/77/EC, Article 2). Biomass differs from MSW (Municipal Solid Waste) or RDF (Refuse ...

-

Manufactured by SolaGen Incorporatedbased in USA

This proven reciprocating grate combustor is ideal for use with difficult to burn biomass fuels. Fully capable of using fuels with moisture contents as high as 55% this combustor features high chrome grate bars, conservative heat release rates, generous furnace volumes, and automatic de-ashing. Ideal for hot gas generation with wet biomass fuel on rotary dryer applications. ...

-

Manufactured by SUGIMAT S.Lbased in SPAIN

Three passes flue gas boilers. High efficiency. Series coil connection without temperature mixing. Upper header cooled by the fluid itself. Easy access for cleaning doors. Minimum ...

-

Manufactured by Thermal Energy International Inc.based in CANADA

DRY-REX low-temperature biomass dryer creates free energy from your existing processes and waste. Where biomass is already in use as a fuel source, DRY-REX can completely eliminate the need to use non-renewable fossil ...

-

by Metener Oybased in FINLAND

We select the rigth process type based on biogas production trials and our 20 years of exprience. If biomass is new for us, then biogas production trials need to be done before binding ...

-

Manufactured by First Biogas International AGbased in SWITZERLAND

Biogas plants for energy production of distillery residues have been in use for more than 30 years. They provide a closed cycle of green energy and materials. They are a perfect complement for every ...

-

Manufactured by LiPRO Energy GmbH & Co. KGbased in EGYPT

The CFD-type walking floor dryer is designed for drying biomass to a specific target moisture content. The drying systems are intended for continuous operation. The drying systems can be supplemented by the LiPRO conveying system and thus individualized e.g. by an extended sieve ...

-

Manufactured by World Thermal Service AB (WTS)based in SWEDEN

It gives the customer an opportunity to convert existing boilers into production units with renewable fuel at a lower capital cost than building a new boiler. The existing fuel is still available and can always be used as back up or topping up. When installing a new combustion system in an existing boiler the customer get a dual or triple fuel installation and can choose the most preferred fuel ...

-

Manufactured by EWK Umwelttechnik GmbHbased in GERMANY

Environmental protection can also be economical: By integrating water/water or water/air heat exchangers into scrubber circuits, large amounts of energy from the exhaust air can be transferred as useful energy into secondary water circuits or outdoor air. As a result, interesting amortizations can also reduce costs for exhaust gas cleaning ...

-

Manufactured by Zhengzhou Dingli New Energy Technology Co.,Ltdbased in CHINA

Biomass energy is second only to coal, oil, and natural gas one of the world's total energy consumption 4th. Experts predict that biomass energy is likely to become an important part of the future sustainable energy system. In the middle of this century, using new technology to produce all kinds of biomass alternative fuels will account for more than 40% of total global fuel consumption. ...

-

Manufactured by Nature Plus, Inc.based in USA

Enzymatic foaming spray that prevents biomass from drying on instruments prior to impingement cleaning– reduces spills and splashing during transport. No water dilution required. Safe for use on rubber, plastic and metal instruments. ...

-

Distributed by Flex Technologies Limitedbased in UNITED KINGDOM

A complete gasifier system includes biomass charging equipment, the gasifier, gas cooling and cleaning system, and control system. The gasifier converts biomass fuel into producer gas. The fuel is batch loaded into gasifier using a bucket charger or inclined ...

-

Manufactured by Jay Khodiyar Machine Toolsbased in INDIA

Our Sawdust Dryer machine, Biomass dryer and Flash Drying System can be used to dry any material such as agricultural waste, forestry waste, municipal solid waste, wood powder. The results of dryer are based on the moisture content of your raw material and the size of the raw material. Our Biomass Briquetting press, Biomass Briquetting machine or Flash Dryer is designed to reduce moisture from ...

-

Manufactured by Zhengzhou Dongding Drying Machinerybased in CHINA

Dongding is dedicated to R&D of biomass rotary dryer for many years, can provide customized biomass dryers to deal with sawdust, wood chips, straw, alfalfa, ...

-

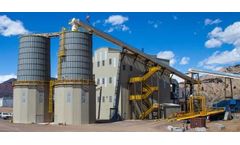

Manufactured by Wellons, Inc.based in USA

Wellons is uniquely qualified to handle all aspects of your electrical generation project. With more than 50 years experience in steam generation systems, we engineer and manufacture a full line of proprietary equipment to burn biomass fuels for the forest products industry. Wellons projects have been completed internationally and include hundreds of successful steam generation systems and ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you