Biomass Fuel Applications

-

Recycling Systems for the engineered fuel, biomass / RDF

Engineered Fuel and waste fuels are an increasingly important resource Waste-derived materials as an alternative to oil, gas and coal, selected and treated with the most up-to-date technologies, can be transferred into energy thanks to their combustible properties, these efforts assist us to obtain zero ...

By Macpresse Europa S.R.L based in Vernate, ITALY.

-

Precision moisture analysis instruments for measuring moisture and ash in biomass

If you produce or consume biomass fuels, you know that quality is critical to your success, and you know that moisture and ash content control are critical to biomass fuel quality. Too much moisture and you get poor efficience and high emissions. Too much ash and you get fouling and slagging. And if either of those is uncontrolled, purchase contracts can fall through. Computrac can ...

By AMETEK Brookfield based in Middleboro, MASSACHUSETTS (USA).

-

Alternative Fuel Production for Energy / Substitute Fuel Production for Energy

Being driven by new legislation, the production of substitute fuel/alternative fuel will be gain momentum in the next few years, as well as the expected increase of recycling rate in municipalities. This means a lot of waste streams can be turned into alternative fuel for the coal fired power plant, cement and lime industry, biomass power plant, or other industrial boiler systems that still burning fossil ...

By eFACTOR3 LLC based in Pineville, NORTH CAROLINA (USA).

-

Material handling equipment for utilities industry

Electric Power Generation, Fossil Fuel Electric Power Generation, Biomass, Alternative Fuels, Sewage Treatment Facilities, Waste Management and Remediation Services, Waste Treatment and Disposal, Solid Waste Combustors and Incinerators, Remediation Services, Materials Recovery, Facilities Waste Treatment and Disposal, Solid Waste Combustors and Incinerators, Remediation ...

By TerraSource Global based in St. Louis, MISSOURI (USA).

-

Measurement solution for Biomass combustion research

The use of alternative combustion fuels that provide a renewable source of energy is a major area of research and investment. Sources of biomass fuels include virgin wood, energy crops, agricultural residues, food waste and industrial waste. Controlling the combustion process of any new fuel and keeping track of the biomass fuel emissions of combustion by-products is important to users of these new ...

By Protea Limited based in Middlewich, UNITED KINGDOM.

-

Rank Equipment for Biomass

Biomass is a vegetable fuel that generally comes from waste, be it forestry, agricultural or industrial. Through Rank equipment, renewable electricity can be generated from the heat produced in a boiler that uses biomass as ...

By Expander Tech S.L. based in La Vall d´Uixó, SPAIN.

-

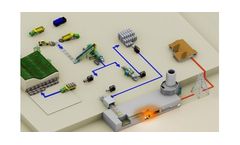

Shredding Plant for Biomass Fuel Processing

AIShred's biomass fuel pre-treatment systems are used extensively in biomass power stations or cogeneration plants. We design fuel pre-treatment solutions according to the type of biomass and boiler type to ensure that the fuel is of the desired ...

By AIShred - GEP ECOTECH Co., Ltd based in Zhengzhou, CHINA.

-

Butterfly Valve for District Heating

In thermal power plants, the combustion of fossil fuels or biomass water is converted into hot steam at up to ...

By Quadax Valves, Inc. - a Daughter Company of Müller Coax Ag based in Bristol, PENNSYLVANIA (USA).

-

Cocoa shells making steam for bean processing

Cocoa processing plants are often located in remote areas with little or no access to fossil fuels. The cocoa shells represent up to 10 % of the processing capacity of a typical plant, and often have no market value. VYNCKE offers combustion systems to convert the cocoa shells into a reliable supply of steam for the sterilization, roasting and grinding process. Our systems effectively address the challenges of cocoa shells as a boiler fuel, and even allow co-generation (combined heat and power ...

By VYNCKE based in Harelbeke, BELGIUM.

-

Multiple fuels in multi media energy plants

MDF production requires large amounts of energy. Most of the demand of energy is thermal: steam for the cooking and refining process, hot gas for drying and thermal oil for the continuous press. VYNCKE offers customized energy solutions, burning a wide variety of process fuels and external fuels (all types of biomass). The energy plant can be designed to produce steam in a direct way (through an integrated steam boiler) or in an indirect way via a thermal oil-steam heat exchanger. The system can be adjusted to ...

By VYNCKE based in Harelbeke, BELGIUM.

-

Biochar in Agriculture

(Bio)char, biomass-charcoal, a charcoal for biological purposes. Use of the word biochar in agriculture is new, but the material has been around as long as land plants and lightning co-existed. It is a naturally occurring element of soils and the use of biochar in agriculture has been adopted by various cultures worldwide for thousands of ...

By Soil Reef LLC. based in Berwyn, PENNSYLVANIA (USA).

-

Conventional Power Generation Systems for Carbon-Negative Energy (CNE)

More than 180 nations set the goal of limiting global temperature increase to 1.5 °C, compared to pre-industrial levels. In order to meet this goal, the Intergovernmental Panel on Climate Change has reported the deployment of large scale “carbon-negative” cycles are needed by 2040. One type of carbon-negative technology that has generated significant interest is biomass energy production combined with carbon capture and storage (CCS), known as BioCCS or BECCS. BioCCS has enormous potential to ...

By Clean Energy Systems, Inc. (CES) based in Rancho Cordova, CALIFORNIA (USA).

-

Monitoring Solutions for Biomass

Biomass Power Plants generates power from biomass fuels such as wood pellets, bagasse and hog fuel. This fuels are susceptible to spontaneous combustion since it can occur at any stage of storage, production or transport. Early detection of fire or combustion is important for safety ...

By VisionTIR based in Malaga, SPAIN.

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you