Methane Biogas Articles

-

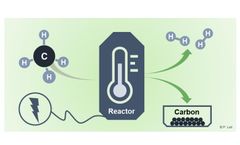

Hydrogen Production and Carbon Capture by Gas-Phase Methane Pyrolysis: A Feasibility Study

In order to reduce carbon dioxide (CO2) emissions, fossil fuels such as oil and natural gas must be replaced by climate-neutral alternatives in the medium and long term. In this regard, hydrogen (H2) is considered as one of the most promising carbon-free energy carriers, since it is already nowadays vastly used in the chemical industry, for instance for refining processes or the production of key ...

-

Roles of Microorganisms in Anaerobic Digestion and Biogas Production

Anaerobic digestion is a biological process in which microorganisms break down organic matter without oxygen and transform them into end-products, including biogas, an energy-rich gas comprised of methane (CH4), carbon dioxide (CO2), and other trace amounts of gases. Anaerobic digestion can be summarized as a four-stage process (1) hydrolysis, (2) acidogenesis, (3) acetogenesis, and (4) ...

-

GWE’s biogas in a balloon continuous to boost both environmental and business performance at NH Foods Australia facility

A far-sighted green energy initiative made by the leading meat processor NH Foods Australia at their Oakey Beef Exports facility, is paying handsome dividends in terms of cleaner wastewater effluent, as well as a reduced carbon footprint and lower energy costs. The Global Water & Energy (GWE) COHRAL™ (Covered High-Rate Anaerobic Lagoon) system was installed ...

-

Synergy Biogas - Case Study

CH4 Biogas formed Synergy Biogas, LLC to build, own and operate a biogas facility at a Synergy Dairy that will produce renewable energy from manure and substrate. Synergy Dairy will provide a site for the facility and supply manure to the facility. The facility will digest manure from the ~2000 milking cows at the dairy along with manure from another Linwood managed dairy in the immediate area ...

-

Safety Considerations at Anaerobic Digestion Plants

Anaerobic digestion is a collection of processes which naturally breakdown organic matter to eventually produce biogas - a methane rich gas which is burned to produce both heat and electricity. The methane can also be used as vehicle fuel or injected into the gas grid. The industry is growing fast and is forecast to continue to do so with many farmers adding bio-gas plants alongside their ...

-

Project Minworth Sewerage Plant Case Study - Case Study

Location Minworth Year 2017 Project Type Biodome MINWORTH SEWAGE TREATMENT SITE SERVICES MORE THAN 1.7 MILLION PEOPLE IN THE BIRMINGHAM AND BLACK COUNTRY AREA. Powered entirely by Biogas produced through Anaerobic Digestion at the site itself. A modern solution was required to future-proof the plant for expansion and development. This unique wastewater engineering solution was ...

-

The gas upgrading plant in Kockte (Germany) - Case Study

Location: Köckte (Germany) Capacity: 350 Nm³/h biomethane Self-consumption: 0,23 kWel/Nm³ crude gas Features: First fully integrated biogas upgrading plant using membrane technology in a three-stage process. Overview of the gas upgrading plant in Köckte The EnviThan gas upgrading plant in the district Altmarkkreis Salzwedel in Saxony-Anhalt is the first fully integrated ...

-

Increasing methane content in biogas and simultaneous value added product recovery using microbial electrosynthesis

Electrosynthesis of multi-carbon compounds from the carbon dioxide present in biogas is a nascent approach towards purification of biogas. Microbial electrosynthesis (MES) cells, fabricated using different electrode materials, were operated using different electrolytes and mixed anaerobic culture as biocatalysts in the cathodic chamber under an applied cathode potential of −0.7 V vs standard ...

-

Quantification of leakage in batch biogas assays

Avoiding leaks is essential for accurate measurement of biogas production by batch assays. Here we present a simple method for detecting leaks and correcting results, based on the change in bottle mass during incubation. Three experiments were carried out using pure chemicals, wastewater sludge, and other complex substrates to test and demonstrate the method, and leaks were detected in all ...

-

Capturing biogas energy to increase your business profits while safeguarding the environment

Methane is a biogas produced from swine or cow manure, as well as food processing and meat packing waste. Methane is a natural gas, that when left uncollected, contributes to the harmful greenhouse gases in the earth’s atmosphere. When biogas is captured under a cover and becomes concentrated, it creates a corrosive and toxic byproduct called hydrogen sulfide. The gas generates a rotten egg ...

-

The Benefits of Biogas Conditioning

Abstract Anaerobic digestion is quickly becoming the choice technology for sewage sludge treatment at wastewater treatment plants, as the methane rich biogas produced is a valuable resource which can be used to generate electricity. In the oxygen restricted environment, a natural by-product of the anaerobic process is hydrogen sulfide, a harmful contaminant. Also present in the biogas are ...

-

Treatment of corn ethanol distillery wastewater using two-stage anaerobic digestion

In this study the mesophilic two-stage anaerobic digestion (AD) of corn bioethanol distillery wastewater is investigated in laboratory-scale reactors. Two-stage AD technology separates the different sub-processes of the AD in two distinct reactors, enabling the use of optimal conditions for the different microbial consortia involved in the different process phases, and thus allowing for ...

-

Effect of solid-state NaOH pretreatment on methane production from thermophilic semi-dry anaerobic digestion of rose stalk

The effects of solid-state NaOH pretreatment on the efficiency of methane production from semi-dry anaerobic digestion of rose (Rosa rugosa) stalk were investigated at various NaOH loadings (0, 1, 2, and 4% (w/w)). Methane production, process stability and energy balance were analyzed. Results showed that solid-state NaOH pretreatment significantly improved biogas and methane yields of 30-day ...

-

Evaluation of treatment potential, biogas generation and sludge properties of an anaerobic claridigester

The anaerobic process for the treatment of municipal and industrial wastewater has been in practice for over a century. Apart from treatment of wastewater, the process has the advantage of lower sludge and biogas production that can save energy. Application of this process in a primary clarifier in such a way that there is simultaneous digestion of primary settled sludge and organic removal ...

-

Chances for Bio-LNG

Abstract An increasing effort is put into the utilization of organic waste streams in anaerobic digesters, producing useful products such as fertilizers and biogas. It becomes increasingly attractive to upgrade biogas to natural gas quality and consequently liquefy the gas to Bio-LNG. DMT Environmental Technology has been developing biogas treatment plants for over 25 years, closely following ...

-

Recovering biomethane and nutrients from anaerobic digestion of water hyacinth (Eichhornia crassipes) and its co-digestion with fruit and vegetable waste

The potential to recover bioenergy from anaerobic digestion of water hyacinth (WH) and from its co-digestion with fruit and vegetable waste (FVW) was investigated. Initially, biogas and methane production were studied using the biochemical methane potential (BMP) test at 2 g volatile solids (VS) L−1 of substrate concentration, both in the digestion of WH alone and in its co-digestion with FVW ...

-

Xebec powers an energy revolution case study

Rumpke Landfill Biogas Project at a Glance: Type: Landfill biogas to pipeline-quality renewable natural gas Claim to fame: One of the largest gas recovery operations of its kind in the world Location: Cincinnati, Ohio Number of acres-landfill: 230 (93 hectares) Waste received annually: Two million tons Plant refining capacity: 15 million cubic feet of landfill gas per day Distribution: 25,000 ...

-

Towards a sustainable use of food waste: influence of urea on biogas production potentials of selected fruit wastes in Addis Ababa, Ethiopia

This study evaluates the influence of adding urea on biogas (methane) production potentials of selected fruit wastes. Using standard methodology, the finding revealed that all the fruit wastes are ideal substrates for biogas production. The ultimate biogas yield on anaerobic digestion of fruit waste feeds, avocado, banana, and mango, are 0.48, 0.57, 0.53 l/g VS without urea supplement and 0.76, ...

-

Do you know everything you need to know about anaerobic digestion?

If you haven’t heard about anaerobic digestion yet, this blog post is the perfect place to start, and if you have, then you will know that technology is an ideal way for businesses to recycle their waste and cut their carbon footprint. Anaerobic digestion is an innovative treatment and an ideal way for businesses in the agricultural and industrial sectors to recycle their waste and cut ...

-

Using biogas for combined heat and power

An integral part of the majority of anaerobic digestion facilities across the world is the CHP combined heat and power (CHP) engine. For the first time builder of a biogas plant, it is often neglected as the focus is on reducing the capital costs of the installation. However, the engine is integral to the plant, and is the key component in the production of renewable electricity, hence the ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you