Combustion Articles

-

The Essence of Attention: Sawdust Charcoal Making Machine

In the realm of sawdust charcoal making machines, attention is not merely a fleeting consideration but a fundamental necessity. The intricate workings of these machines demand a meticulous eye and a vigilant mind. Let us delve into the nuances of this crucial aspect. The process of sawdust charcoal making begins with the selection of raw materials, primarily sawdust—a byproduct of wood ...

-

Biomass alternative fuel: co-combustion of coal explodes!

Biomass fuel blending in Europe Europe has used biomass fuels on a large scale for more than 30 years. The UK has adopted the direct-fired co-combustion route for large coal-fired power plants and has continuously increased the proportion of biomass coupling. Through policy drive, cost management and safety control, it achieved multiple 100% biomass-fired thermal power plants in 2018. ...

-

The Core Component: Plastic Pyrolysis Reactor

In the realm of plastic pyrolysis, the reactor stands as the nucleus, orchestrating the transformation of discarded plastics into valuable commodities. Within this intricate apparatus lies the essence of plastic waste management innovation. Plastic pyrolysis reactors are marvels of engineering, designed to initiate and sustain the pyrolytic process. This process involves subjecting plastic ...

-

What You Ought To Understand About The Continuous Pyrolysis Plant

Often known as the fully-automatic pyrolysis plant, continuous pyrolysis plants use automated screw feeders that feed raw materials directly into a reactor. The discharging and feeding occurs at the same time without interruptions, allowing the plant to operate 24/7. The continuous pyrolysis plant are specifically made for profits, safety, and they are eco-friendly. These machines are not simply ...

-

Upgrading to ABB Flame Scanners: A Seamless Transition for Domtar’s Pulp & Paper Power Boiler - Case Study

In the world of industrial combustion, maintaining operational efficiency while ensuring safety standards can be a challenging balancing act. Domtar’s Espanola pulp & paper mill in Ontario, Canada, faced such a challenge with their power boiler #9. The need to replace aging flame scanners without undergoing a time-consuming and costly safety recertification process led them to ABB's ...

-

Revolutionising Clean Combustion with Advanced Analytical Tools

In the quest for sustainable energy solutions, clean combustion technology stands out as a beacon of hope. This groundbreaking approach not only aims to significantly reduce harmful emissions but also enhances energy efficiency across numerous sectors. As we stride towards greener practices, the spotlight shines on the indispensable role of sophisticated analytical instruments in monitoring, ...

-

Green Hydrogen: An Analytical Perspective on Clean Energy

Introduction In the quest for a sustainable and cleaner future, Green Hydrogen emerges as a beacon of hope that not only addresses our immediate energy needs but also lays the foundation for a transformative tomorrow. As we stand at the crossroads of environmental challenges and the need for clean energy, Green Hydrogen shines as a powerful solution that holds immense potential. The future ...

-

Methoxytriethyleneoxypropyltrimethoxysilane

Methoxytriethyleneoxypropyltrimethoxysilane can form covalent bonds with the polymer chains, creating a three-dimensional structure that is more resistant to degradation. Thus, it is frequently used as a crosslinking agent in polymers. Methoxytriethyleneoxypropyltrimethoxysilane provides the abilities of reducing friction between surfaces and resistance to adhesive. So, it can be used as a ...

-

Optimizing Resource Efficiency: Setting Up a Continuous Pyrolysis Plant

In the realm of sustainable waste management and resource recovery, the installation of a continuous pyrolysis plant stands out as a cutting-edge solution. This sophisticated process not only contributes to environmental conservation but also offers economic advantages. Let's delve into the meticulous steps involved in establishing a continuous pyrolysis plant and explore the factors influencing ...

-

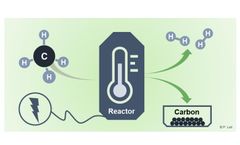

Hydrogen Production and Carbon Capture by Gas-Phase Methane Pyrolysis: A Feasibility Study

In order to reduce carbon dioxide (CO2) emissions, fossil fuels such as oil and natural gas must be replaced by climate-neutral alternatives in the medium and long term. In this regard, hydrogen (H2) is considered as one of the most promising carbon-free energy carriers, since it is already nowadays vastly used in the chemical industry, for instance for refining processes or the production of key ...

-

Sawmill Waste Treatment Methods: Wood Pyrolysis

Introduction Sawmills play a pivotal role in the timber industry, yet they generate substantial waste that demands efficient management. This article explores the advanced method of wood pyrolysis as a promising avenue for treating sawmill waste, providing both environmental benefits and resource recovery. Wood Pyrolysis: A Technical Insight Pyrolysis Process Fundamentals Wood pyrolysis is a ...

-

Navigating the Nuances: Matters Need Attention in the Plastic Pyrolysis Process

Crucial Role of Feedstock Composition The success of the plastic pyrolysis process hinges on the diverse composition of plastic feedstocks. From the ubiquitous polyethylene to the robust polypropylene, understanding the intricate mix is essential. Any deviation from the optimal composition can significantly impact the efficiency and output of the process. The initial stage demands a discerning ...

-

Exploring the Ceramic Fiber Paper in Incinerator

In the realm of advanced materials, ceramic fiber paper has emerged as a versatile and indispensable product, finding applications across a wide range of industries. Engineered from high-temperature alumina-silica fibers, this lightweight and flexible material boast exceptional thermal insulation properties. In this article, we delve into the characteristics, manufacturing process, and diverse ...

-

How to Choose Incinerator Refractory Brick

Incinerators, crucial in waste management and industrial processes, rely on high-quality refractory bricks to withstand extreme temperatures and harsh conditions. Selecting the appropriate refractory brick is paramount for optimal performance, durability, and safety. In this article, we will discuss the key considerations when choosing refractory bricks for incinerators.Temperature ...

-

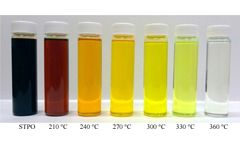

Environmental Impacts of Pyrolysis Oil Production and Utilization

In the quest for sustainable energy sources and waste reduction, pyrolysis oil has emerged as a promising player. This remarkable substance is obtained through the process of pyrolysis, which converts organic materials into a valuable liquid fuel. While it offers a plethora of benefits, it's crucial to scrutinize the environmental impacts of both its production and utilization. The Eco-Friendly ...

-

How to Combine Charcoal Making Machine with the Activated Carbon Industry

In an era where sustainability and eco-consciousness reign supreme, the combination of charcoal making machines with the activated carbon industry stands as a shining example of innovation and environmental responsibility. This article explores the intricate fusion of these two seemingly distinct sectors, revealing the promising synergies and potential benefits. Introduction The Importance of ...

-

Monolithic Refractory Products for Incinerators

Incinerators uphold an indispensable role in waste management, serving to transform diverse categories of refuse into energy or reducing them to residues secure for the environment. To underwrite decisive and continuous operation under towering temperatures and rigorous conditions, the tactful selection of refractory materials proves paramount. Among the broad spectrum of refractory solutions ...

-

Benefits of Biomass Pyrolysis Plant to Process Coconut Shells

Coconut shells, often seen as waste, hold untapped potential in various industries. These sturdy byproducts of the coconut industry are traditionally discarded or underutilized, leading to environmental concerns and missed opportunities for resource optimization. The Role of Biomass Pyrolysis Plant The biomass pyrolysis plant offers a sustainable and eco-friendly solution to harness the hidden ...

-

Revolutionizing Recycling: The Tyre Pyrolysis Process for Transforming Tires into Fuel

The process of converting waste tires into fuel is a highly efficient and eco-friendly method known as the tyre pyrolysis process. This innovative process involves breaking down the complex carbon chains found in tires into valuable liquid and gaseous products. But what are these fuels used for, and what are the key steps and benefits of recycling tires into fuel? The fuel produced through the ...

-

Considerations Regarding the Wood Charcoal Making Machine

Did you know there's a lucrative way to manage the vast amount of wood waste generated by the manufacturing and construction industries every year? Have you been wondering what can be done with the mountains of wood scraps and other organic waste that would otherwise end up rotting in a landfill? A Beston wood charcoal making equipment for sale could be the solution to turn unusable wood into ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you