Flare Hydrocarbon (Flares) Equipment

-

Manufactured by AEREON, part of Cimarron groupbased in USA

The Chimera was developed to flare liquid hydrocarbons without liquid fallout or soot formation (smoke). These burners provide excellent service for various onshore applications that require high destruction efficiency of liquid hydrocarbons. When oil is flared, a high pressure media such as an air, gas, or steam is required to ...

-

Manufactured by Pollution Systems Inc.based in USA

An Enclosed Flare (or Vapor Combustor) is an air pollution abatement technology specially configured to handle high VOC streams. The Enclosed Flare can accommodate a high-energy process discharge stream with excess air for combustion. The heat value of the process stream is significant and can potentially provide most of the necessary ...

-

Manufactured by AEREON, part of Cimarron groupbased in USA

The Peacock Burner was developed to flare liquid hydrocarbons without liquid fallout or soot formation (smoke). These burners provide excellent service for well testing operations and have been used in applications in the Gulf of Mexico and Arabian Gulf. When only oil is flared, a high pressure air or gas source is required to provide ...

-

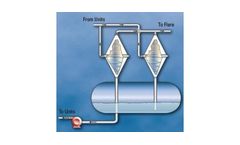

Manufactured by Epcon Industrial Systems, LPbased in USA

Principle: A combination of tangential, centrifugal and gravitational forces resulting in far more effective and superior separation of multiple fluid phases - supersonic, sonic and subsonic ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you