Coal-fired Power Applications

-

Premium

Industrial Boilers Application Note

Industrial boilers are used to produce steam, whicl can be used to turn electrical turbines to generate power or provide heat in an industrial process. In all cases, it is important to monitor and diagnose combustion conditions within the boiler to improve its operation, and safety. Key measurements can support the optimisation of the combustion process and minimise emissions. Monitoring the boiler can also provide important information on the refractory or waterwall condition. AMETEK Land's products support ...

By AMETEK Land Instruments International Ltd based in Dronfield, UNITED KINGDOM.

-

Premium

Desulfurization on-line continuous monitoring solution

SO2 is one of several important pollutants in the atmosphere, SO2 from the atmosphere can stimulate people's respiratory tract, abate respiratory function, and lead to respiratory resistance decreased, induce various inflammation of respiratory tract, harm to human health. SO2 also is harm to many plants. SO2 and its generated sulfuric acid mist can corrode metal surfaces and cause damage to paper products, textiles, leather products. It may also form acid rain, which is serious harm to the ecological system and ...

By Hangzhou Chunlai Technology CO., Ltd. based in Hangzhou, CHINA.

-

Premium

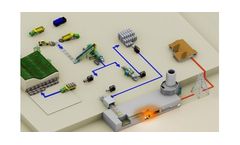

Gas monitoring during industrial process

EM-5 CEMS Coal power plant: Entrance of SCR denitration device, NOx O2 Exit of SCR denitration device: Measure remanet NH3 after reaction and avoid blocking by crystallization, NH3; Calculate denitrification rate with Nox input, NOx O2 Gas-fired power plant: Counting tail gas emission and realtime concentration, NOx O2 SO2 Temperature pressure flow dust ...

By Hangzhou Chunlai Technology CO., Ltd. based in Hangzhou, CHINA.

-

Premium

Processing of Alternative Fuels for the energy industry

RDF is a fuel that is normally produced from waste with high calorific value. The original waste comes from households, industry and commerce and is processed for energy extraction; it is meant for co-incineration plants and replaces standard fuels (e.g. coal) in production plants for cement, power plants or other co-incineration ...

By Lindner-Recyclingtech GmbH based in Spittal/Drau, AUSTRIA.

-

Premium

Gas detection in energy industry

Gas detection requirements for power generation can vary widely based on the fuel source, which includes coal, oil, natural gas and nuclear. Regardless of the type of power facility, gas, fire and other hazards pose significant risk to employee safety and also can disrupt the supply of energy to commercial and residential customers. At Teledyne Gas and Flame Detection, our wide range of gas detection products meets the needs of all forms of power generation. Our century of experience, combined with advanced system ...

By Teledyne Gas and Flame Detection based in Arras Cedex, FRANCE.

-

Premium

Process instrumentation and analytics solutions for power industry

Siemens has a wide portfolio of products for process instrumentation, weighing and process analytics. Our solutions make it possible to economically address the growing energy demand as well as expanding environmental and safety ...

By Siemens Industry, Inc. - Process Analytics based in Houston, TEXAS (USA).

-

Premium

Machine condition monitoring for power generation

Power plants are expected to operate 24 hours per day, 7 days per week. Downtime and equipment derating (when a generator fails to deliver power at its rated capacity) can cost a power plant thousands of dollars per hour. The cost of replacing failed equipment is also extremely high. Vibration analysis by itself is not enough to anticipate catastrophic failures. Oil analysis is often able to detect problems at a much earlier stage than vibration analysis. This is why more and more power plants are bringing oil ...

By AMETEK Spectro Scientific based in Chelmsford, MASSACHUSETTS (USA).

-

Premium

Syngas Analyzer Applys in Gasifier

Coal gasifier: The coal gasifier can be divided into four modes by the movement pattern of the coal in the gasifier: fixed bed (moving bed), fluidized bed, entrained bed and molten bed. While it can be summarized to atmospheric and high pressure styles according to the gasification operating pressure. Based on the feeding method, the coal gasifier contains solid and liquid feeding manners. In the light of the residue-discharge mode, it can be classified into solid and liquid patterns. In industry, the typical ...

By Enviro Solutions Technology Co.,Ltd based in Wuhan, CHINA.

-

Premium

Power generation solutions for pulp and paper production industry

The pulp and paper industry requires large amounts of power and heat in forms of hot air and steam. Solar’s best pulp and paper energy solutions use gas turbine-based cogeneration, better known as Combined Heat and Power (CHP). Cogeneration and CHP installations can reduce our customers’ carbon footprint and reduce energy consumption in pulp and paper production. Estimate your annual operatings savings for your plant using our value estimating ...

By Solar Turbines Incorporated based in San Diego, CALIFORNIA (USA).

-

Premium

Reciprocating Engine Generators Application Note

Reciprocating Engine Generators are a trusted method of providing reliable electric power for small-to medium-scale operations.Driven by the benefits of lower costs and risks, gas-powered reciprocating engines are increasingly being used in place of combined-cycle gas turbine power plants.While the reciprocating engines deliver greater flexibility, especially with regards to the use of renewable fuels such as biogas, they still require precise gas monitoring to ensure emissions limits are met.AMETEK Land’s ...

By AMETEK Land Instruments International Ltd based in Dronfield, UNITED KINGDOM.

-

Evaporators for Power Industry

EVALED evaporators treat or minimize wastewater from the Power Generation Industry. Flue gas desulfurization effluents require different kinds of treatments depending on the type of fuel, water sources, and environmental regulations. Coal, Gas, Solar, Nuclear. Wastewater treatment for a more sustainable power ...

By EVALED - Evaporator - Veolia Water Technologies Italia Spa based in Zoppola (PN), ITALY.

-

Filtration systems & solutions for energy sector

Porvair Filtration Group have supplied a comprehensive range of filtration and separation products to the energy market for many years. We supply all major sectors of the power generation, distribution and supply industry, and our technology is used over a wide range of applications. These include, but are not limited to, the distribution of natural gas, conditioning and treatment of fuel oils, hydrocarbons and produced water, clean coal technologies, gasification and fuel cell technology. Our unrivalled ...

By Porvair - Filtration Group based in Fareham, UNITED KINGDOM.

-

Mining solutions for mining industry

Mining is a key sector of the Polish economy, which will continue to be the guarantor of the energy security of the country in the next decade. The Central Mining Institute has a huge research, apparatus and human resource potential, focusing on providing solutions for the mining industry. A priority area of research is the safety of the work and the new coal technologies the development of which determines the future of Polish mining ...

By The Central Mining Institute based in Katowice, POLAND.

-

Coal storage for the energy industry

CST Covers aluminum domes are custom designed around a bulk storage facilities specific clearance requirements, basin configuration and bulk handling equipment. Structurally efficient and lightweight, they maximize bulk storage capacity, minimize foundation costs and provide dependable protection form the elements while remaining virtually maintenance ...

By CST Industries Inc based in Kansas City, MISSOURI (USA).

-

Coal pulverizing for the coal industry

Columbia Steel has established itself as a manufacturer of quality replacement parts for coal pulverizers and ash crushers used in power plants. ...

By Columbia Steel Casting Co., Inc. based in Portland, OREGON (USA).

-

Energy management

With energy costs skyrocketing, companies are looking for ways to optimize energy usage and cut costs, but maintain production output. Companies now capture details of energy use, such as peak and non-peak use and type of fuel used— natural gas, steam, coal, etc. There are different programs such as Energy Star that companies are using for guidance and ...

By Lisam Systems | Perillon based in Ecaussinnes, BELGIUM.

-

Primary air control for coal-fired power plants

Power Generation Combustion Air Measurements: The need for accurate, repeatable & reliable combustion air measurements in power generation plants is critical to efficient operation and safety throughout the entire facility and processes. Coal-fired power plant applications pose a number of challenges to obtaining these critical flow measurements includ¬ing large ducts, limited metering runs, poor velocity and temperature profiles, high vibration, temperatures up to 750° F and dirty 'Fly Ash' laden ...

By Kurz Instruments, Inc. based in Monterey, CALIFORNIA (USA).

-

Recycling Systems for the engineered fuel, biomass / RDF

Engineered Fuel and waste fuels are an increasingly important resource Waste-derived materials as an alternative to oil, gas and coal, selected and treated with the most up-to-date technologies, can be transferred into energy thanks to their combustible properties, these efforts assist us to obtain zero ...

By Macpresse Europa S.R.L based in Vernate, ITALY.

-

Hydrogen gas solutions for grid balancing sector

Decarbonising the production of hydrogen, enabling a green transport fuel for trains. The ongoing trend to deploy more renewable power sources is a positive step towards reducing dependency on fossil fuels, but it causes some big issues for electricity grid operators. Balancing the grid is becoming more challenging, because renewables are increasing the temporal mismatch between supply and demand on all timescales. Conventional grid balancing techniques cause CO2 emissions (ramping up a gas or coal power plant), ...

By ITM Power based in Sheffield, UNITED KINGDOM.

-

Hydronix Sensors for Coal

The moisture content of coal may be measured. Pulverised Coal Injection is a common method of burning low grade or low carbon coal to create electricity. Small particle size low grade coal is measured as it is injected into the burners. The rate of injection is a direct function of the moisture content of the coal. As the material becomes drier the throughput is reduced to avoid serious overheating which can result in very significant financial loss and plant ...

By Hydronix based in Normandy, UNITED KINGDOM.

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you