Energy Industry Equipment

-

ShowcaseManufactured by Zeltex LLCbased in USA

Decades of expertise in portable octane, cetane and bio-fuel with lab-accurate analysis. 45 State Agencies have used Zeltex portable fuel octane analyzers over the years, making the ZX-101 series the gold standard in portable fuel testing. The main way that fuel is analyzed is through a CFR engine, which takes time, costs a lot of money, and destroys the sample. Our portable fuel octane analyzers ...

-

ShowcaseManufactured by Avtron Power Solutionsbased in USA

The 2500 is “the load bank of choice”, as they provide the right mix of high capacity, transportability, ease of use, and reliable Avtron construction. ...

-

ShowcaseManufactured by Delta Steam Systems (DSS)based in SOUTH AFRICA

The DSV Venturi Steam Traps are designed for multipurpose applications from line drainage, trace heating, through to medium heat exchanger ...

-

ShowcaseManufactured by EnviTec Biogas AGbased in GERMANY

Waste materials and by-products are accrued in conjunction with every single manufacturing operation, such as enterprises associated with the food and restaurant sector, the fuel industry, the cosmetics sector and the animal husbandry sector. However, the quantity of organic waste produced by the citizenry is also significant for communes – about half a tonne per year per person. In ...

-

ShowcaseManufactured by Solar Turbines Incorporatedbased in USA

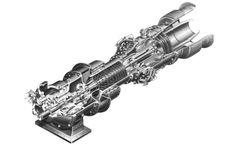

A gas turbine engine is a type of internal combustion engine. Essentially, the engine can be viewed as an energy conversion device that converts energy stored in the fuel to useful mechanical energy in the form of rotational power. The term “gas” refers to the ambient air that is taken into the engine and used as the working medium in the energy conversion ...

-

ShowcaseManufactured by Solar Turbines Incorporatedbased in USA

Solar’s C16 family of gas compressors are designed for single-body and tandem applications with the Saturn® 20, Centaur® 40, Centaur 50, Taurus™ 60, Taurus 70, Mars® 90,Mars 100 andTitan™ 130 gas turbines. These compressors combine high efficiency and wide flow range with a robust design and ease of restaging. They are particularly well suited for low flow and high ...

-

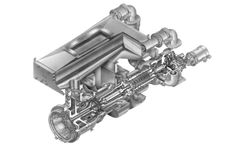

ShowcaseManufactured by Solar Turbines Incorporatedbased in USA

Solar Mobile Turbomachinery (SMT) is the best solution for oil field power, remote power and trailer power in the industry, and in emergencies such as natural disasters where quick power is essential. The single trailer design is a complete mobile power plant with wide fuel composition flexibility. This solution is based on the 5.7 MWe Taurus 60 gas turbine generator set – a proven industry ...

-

PremiumManufactured by USA Borescopesbased in USA

4mm Diameter Two – Way Articulating Fiberscope with internal LED Light ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The Mars® gas turbine has been engineered for very high reliability and durability as well as ease of maintenance. Like Solar's other gas turbine families, Mars gas turbines are available for compressor, generator, and mechanical-drive ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

Centaur® gas turbines are at work today in thousands of installations both offshore and on land ranging from arctic to tropical ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The Mercury™ recuperated gas turbine is a product of Solar's commitment to the U.S. Department of Energy's Advanced Turbine Systems (ATS) program. It features the highest electrical efficiency for a gas turbine in its size range and an ultra-low emissions ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The Mars® gas turbine has been engineered for very high reliability and durability as well as ease of maintenance. Like Solar's other gas turbine families, Mars gas turbines are available for compressor, generator, and mechanical-drive ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The Mars® gas turbine has been engineered for very high reliability and durability as well as ease of maintenance. Like Solar's other gas turbine families, Mars gas turbines are available for compressor, generator, and mechanical-drive ...

-

PremiumManufactured by Hilliard Corporationbased in USA

Hilliard supplies standard and custom brake caliper mounting kits and brackets for use with all Hilliard brake models. Fabricated of welded steel construction with painted finish, Hilliard mounting bracket models are available to accommodate from one to eight calipers per disc. Hilliard can also supply non-standard disc and hub sizes to meet your specific applications. ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The family of Taurus™ gas turbines represents years of intensive development by the engineering and manufacturing groups at Solar and offers many advanced ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The family of Taurus™ gas turbines represents years of intensive development by the engineering and manufacturing groups at Solar and offers many advanced ...

-

PremiumManufactured by Hilliard Corporationbased in USA

The Inferno Fire racing clutch is the latest engineered product for the racing industry. The Fire clutch includes all of the design advantages of the Flame with several new features that make the Fire the best drum clutch available on the ...

-

PremiumManufactured by Hilliard Corporationbased in USA

The Hilliard M300 brake caliper is a hydraulic applied, spring retracted brake caliper for use in heavy duty industrial applications. The brake caliper is suitable for outdoor applications and has been designed for use in many different extreme environments. The M300 brake caliper is capable of producing a maximum 10,600 LBF (47 kN) of braking force at 1600 PSI (110 Bar) and has been designed for ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

The Titan 130 continues Solar Turbines' legacy of highly reliable and durable gas turbine engines with low maintenance requirements. Like our other turbines used for power generation, the Titan 130 is also available for compressor and mechanical-drive ...

-

PremiumManufactured by ForeverPure Corporationbased in USA

Deep Cycle Battery with Cover, 24 Volt, 816 Ah (at 20 hr.). Some 24 Volt batteries do not come with a cover, the image is for illustration purposes ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you