Biodiesel Equipment

-

PremiumManufactured by Metrohm AGbased in SWITZERLAND

The 893 Professional Biodiesel Rancimat is an analysis system for easy and safe determination of the oxidation stability of biodiesel (fatty acid methyl ester, FAME) and biodiesel blends in accordance with EN 14112, EN 15751 and EN 16568 standards. With eight measuring positions in two heating blocks. The built-in display shows the ...

-

PremiumManufactured by Metrohm AGbased in SWITZERLAND

The 892 Professional Rancimat is an analysis system for the simple and safe determination of the oxidation stability of natural fats and oils with the well-established Rancimat method. With eight measuring positions in two heating blocks. The built-in display shows the status of the instrument and each individual measuring position. Start buttons for every measuring position enable the ...

-

PremiumManufactured by AMETEK Spectro Scientificbased in USA

The InfraCal 2 Biodiesel Blend Analyzer for measuring percent biodiesel in diesel is the ideal solution where a quick, accurate, on-site measurement is required and a single, repetitive biodiesel blend analysis is needed. The InfraCal 2 ATR-B is based on proven IR technology, originally developed by Wilks, and used by fuel distributors, ...

-

Manufactured by ASI Standardsbased in USA

Free Total Glycerin Stock Solutions, standards 1- 6 are 5 ml, also includes one 5 ml of MSTFA and 250 ml of Heptanes ...

-

based in USA

The concept of co-locating biodiesel at ethanol plants has been a natural evolution of corn ethanol facilities that extract corn oil. Today, as biodiesel production requirements are becoming more stabilized, integrating biodiesel at an ethanol facility can be a highly effective means to improve profits associated with corn oil ...

-

Manufactured by Maritime BioFuels (Foxcreek Consulting Services)based in CANADA

Biodiesel is an environmentally friendly, renewable fuel produced by the esterification of fats and oils with a primary alcohol. The fats and oils are derived from both animal and plant sources. This process allows for the thicker glycerin portion of these fats and oils to removed. The remaining biodiesel is much less viscous and can be ...

-

Manufactured by Universal Biofuels Private Limitedbased in INDIA

Biodiesel, or fatty acid methyl ester, is a renewable chemical and fuel commonly produced from vegetable oil or animal fat. This non-petroleum based product can be used as diesel fuel, textile lubricant and industrial heating oil fuel. Biodiesel is an environmentally friendly and bio-degradable. Our biodiesel conforms to ASTM and EN ...

-

Manufactured by Chevron Renewable Energy Groupbased in USA

Chevron Renewable Energy Group is a full-service fuel provider. In addition to selling neat biodiesel and ultra-low sulfur diesel (ULSD), we also supply blended fuel at our terminal locations across the U.S. This is a good option for customers who don't want to do their own fuel blending. We can get you the blend level you want, from B2 to ...

-

Manufactured by ERC Emissions-Reduzierungs-Concepte GmbHbased in GERMANY

Additives for all diesel qualities: Every diesel engine needs care. It makes no difference whether it is operated with conventional diesel fuel or biodiesel. Long standstill times or fluctuating fuel qualities can have a strong impact on the performance of diesel engines, and carbonisation on the injection nozzles can increase fuel ...

-

Manufactured by U.S. Freedom Bio Fuels, LLCbased in USA

80 Gallon Preheat Tank with 4500 Watt Stainless Steel Element. Galvanized Removable Dust Covers for Both the Preheat Tank and the Settlement Tank. 130 Gallon Settlement Tank with 5500 Watt Stainless Steel Element for Methanol Flash. Fuse Protected Circuitry with UL Approved Control Panel. Timer Controlled Processor. One ½ HP Pump. One ¾ HP Pump. 75 Gallon Spill Containment Pallet. ...

-

Manufactured by Vobis LLCbased in USA

We have successfully designed and constructed evaporator systems to improve the vital evaporation and distillation stages of our clients' Biodiesel facilities. We have successfully provided optimization of existing biodiesel production systems as well as provided new separation systems. We trouble shoot existing biodiesel production ...

-

Manufactured by Sierra Sales Double Wall Plastic Tanksbased in USA

Biodiesel processing requires a variety of processing storage tanks. Snyder has conducted chemical compatibility testing on B100. Their compatibility testing showed that Snyder’s uniquely processed HDLPE and XLPE resins are compatible with B100. From our chemical compatibility testing, Sii recommends ONLY above ground 1.9 specific ...

-

Manufactured by Bio Energy Shanghai Co., Ltd (BioGTS)based in CHINA

BioGTS Biodiesel biodiesel process produces renewable biodiesel. A wide selection of production materials: for example, waste biomass oil and grease from food processing plants, restaurants and municipal solid waste, oily parts separated from biological waste, wastewater, sewage sludge, and animal and fish processing and production Waste ...

-

Manufactured by ASI Standardsbased in USA

Sulfur in Biodiesel Calibration Standards, 6 standards per set, Low Level, 100 ml each, Concentrations @ Blank, 5, 10, 15, 20, and 25 ...

-

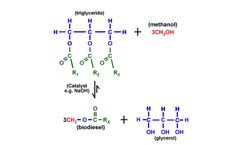

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

Biodiesel is produced via the transesterification of fats as shown by the chemical reaction to the left. There are some excellent publications relating to Biodiesel production. At Biofuel Systems we have been most impressed with the comprehensive Biodiesel Handbook and have made this available on our online ...

-

Manufactured by Dotan Technologiesbased in ISRAEL

Jatropha is one of the most promising crops available today for biofuel, however the labor intensive harvest is blocking its large-scale success.Jatropha is the perfect choice for biofuel, as it doesn’t require large amounts of water or fertile soil, so it doesn’t compete with edible crops. Harvesting of the Jatropha crop is currently done manually, requiring 400-800 man-hours to ...

-

based in INDIA

Arslan Enginery is having the complete process and technology of advanced (ATFE) process to produce biodiesel from all kind of crude vegetable oil. The biodiesel plant design are simple as the main equipment involved in it are filmed evaporators and distillation column. The one more option in plant biodiesel are to get an additional ...

-

Manufactured by Biofuel Systems Group Limitedbased in UNITED KINGDOM

We supply a comprehensive range of pumps. Many are available through our online shop, but please note the online shop offers only a fraction of the complete range. If you cannot find the exact pump you are looking for there, please e-mail us with details of your application and we can almost certainly find the right pump for ...

-

Manufactured by Chevron Renewable Energy Groupbased in USA

InfiniD™: A biodiesel solution that can provide engine performance and emissions benefits to fleets looking to reach lower carbon goals economically. Flexible feedstocks. Consistent supply. InfiniD™ is produced from multiple feedstocks, including recycled cooking oil, distillers corn oil, animal fats and vegetable oils, which ...

-

Distributed by Citigate, S.L.based in SPAIN

Product made from biodiesel distillation, also known as Bio Heating Oil (BHO), this product is most appropriate for power ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you