Energy Industry Services

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

What equipment to utilize represents only part of the decision process in a gas turbine acquisition process. Other decisions, such as when to proceed and whether to buy or lease, can be equally important. Money to purchase assets is often scarce, even for the biggest of companies. As a result, equipment acquisition is often delayed well past the time it is needed. Solar offers leasing, and ...

-

PremiumManufactured by Gazpack B.V.based in NETHERLANDS

Sulaway® only needs 2 days of maintenance shutdown per year and is far cheaper than usage of active ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

Our focus is to help your business power the world by providing the parts you need with Shop ...

-

PremiumManufactured by Advanced Energy Industries, Inc.based in USA

Decrease variability in maintenance costs. Our complete offerings of whole-box, extended warranties can be enhanced based on your business needs and are available for: New and used products purchased from Advanced Energy. Products approaching tool warranty expiration dates. Products repaired by Advanced Energy. Advanced Energy also offers calibration contracts that can be purchased ...

-

PremiumManufactured by Advanced Energy Industries, Inc.based in USA

The mission of the Advanced Energy services organization is to deliver consistent value-added service so you can focus on your business. Our highly trained and dedicated Field Service Engineers (FSEs) are ready to partner with you to deliver the right sensing solutions with the best performance and ...

-

PremiumDistributed by 3R-Machinery (by Shred-Tech)based in USA

Service escalation with 3R-Machinery means you can always get the advice and information you require at any time. Whether you have questions or require resources, advice, or support information, our engineers, mechanics, and shredding experts have got your back. We also ensure that all equipment has remote telematics capabilities for equipment monitoring, adjustment programming, preventive ...

-

PremiumManufactured by Maschinenfabrik Gustav Eirich GmbH & Co KGbased in GERMANY

The installation and attending to production in the start-up phase of systems is the first step in LifeCycle Service from EIRICH. For us it starts with the site supervision before delivery, which is part and parcel of the package. Our worldwide presence enables us to identify local obligations at an early stage and to meet them in full. ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Anaerobic Digestion has been used historically for digesting waste activated sludge to reduce the volume for disposal and also for treating high strength, low volume organic wastes to save energy. Recently, corn silage, food waste, animal manure, and slaughterhouse waste and other materials with a dense organic content are used as effective feedstock for the production of biogas. With increasing ...

-

PremiumManufactured by EnviTec Biogas AGbased in GERMANY

Our formula for the perfect maintenance package. For us, the customer is always right. Even for maintenance work. Depending on the maintenance package selected, our technical experts can be booked on a time and material or flat-rate basis. We advise, you decide and we complete the ...

-

PremiumManufactured by Advanced Equipment and Services, Incbased in USA

An experienced team produces a comprehensive assessment of the plant providing a customized report which ultimately reduces cost and improves efficiency of the plant. This report may involve implementing energy-saving technology, minimizing inefficiencies and improving control methods. After report is produced and recommendations are reviewed, with your approval, we target ways to reduce costs ...

-

PremiumManufactured by EnviTec Biogas AGbased in GERMANY

We keep it in stock to keep your plant going! At EnviTec, ‘just in time’ is a concept, not a cliché, and we are constantly expanding our warehouse capacities. Complementing our established sites in Lohne and Friedland, our Calbe/Saale facility offers 160 m2 of storage for large parts and a small parts unit of around 80 ...

-

PremiumManufactured by Advanced Energy Industries, Inc.based in USA

Increase film quality and stay at the forefront of your market. Industrial thin film coating is swiftly adapting as consumer demands drive stringent performance requirements. As a world leader in industrial-coating power systems, Advanced Energy’s process expertise and manufacturing capabilities help give you a competitive advantage. Benefit from local engineering support, worldwide ...

-

PremiumManufactured by Hermann Sewerin GmbHbased in GERMANY

You can trust our more than 80 years of experience in testing gas pipeline ...

-

PremiumManufactured by Advanced Energy Industries, Inc.based in USA

AE’s more than thirty-year track record of world-class service established a high bar for bankability and reliability in the solar inverter industry. Entrust the responsibility of performing annual inverter maintenance to the OEM’s employees and further reinforce your stakeholders’ confidence in the project’s long-term power production. AE’s engineering and quality ...

-

Premiumby OHMSETTbased in USA

Ocean Wave & Marine Current Energy Testing Capabilities. The Bureau of Safety and Environmental Enforcement (BSEE) collaborates with research institutions and industry on testing wave and current energy systems at Ohmsett. Our wave and towing test tank is available for R&D and testing of large to full-scale equipment processes for ocean wave and current ...

-

PremiumManufactured by Solar Turbines Incorporatedbased in USA

Solar Turbines offers a wide range of financing options to support your project. Financing can be based on total cost and can cover engineering, equipment, construction, and commissioning work. As you develop your project, Solar has the resources to coordinate with international financing partners as well as Caterpillar ...

-

PremiumManufactured by Solexperts AGbased in SWITZERLAND

Knowledge of the in-situ primary stresses in the subsurface is an essential prerequisite for the design of underground structures with regard to their dimensioning and long-term stability. The only method for direct measurement of in-situ stresses is the hydraulic fracturing (HF) or hydraulic testing of pre-existing fractures (HTPF) method. For both methods, a test section is isolated in a ...

-

PremiumManufactured by EnviTec Biogas AGbased in GERMANY

Why should you decide to use the EnviTec Biogas Service? ...because your biogas plant is in safe hands with us! As biogas all-rounders, we know biogas generation processes better than anyone and offer a service package that guarantees your peace of ...

-

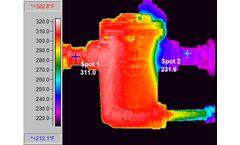

PremiumManufactured by Delta Steam Systems (DSS)based in SOUTH AFRICA

Are Your Steam Traps Working Correctly? All conventional steam traps leak eventually. “How long will they leak before being noticed?” A steam trap survey will help you solve leaks and reduce costly energy loss. Total steam leak percentages range anywhere between 10% to 55%, depending on factors such as: Type of steam trap (thermodynamic, inverted bucket, etc.). Quality of water ...

-

PremiumManufactured by InterOcean Systems LLCbased in USA

InterOcean Systems can perform winch maintenance services such as unspool, clean, lubricate, and re-spool. Our 40HP cable reel has a built-in, programmable levelwind and is capable of handling over 15,000 meters of cable weighing up to 32,000lbs. Our tensioning rig (bull wheel style) is capable of providing up to 10,000lbf (44.5 kN). Tensions are adjustable on the fly to ensure that your cable is ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you