- Home

- Companies

- CrossTek Membrane Technology LLC

- Applications

- Membrane-Based Technology for ...

Membrane-Based Technology for Coal-to-Chemicals (CTX) - Mining - Coal Mining

CTX waste effluents typically contain salts, minerals, sulfides, chlorides, ammonia, oil & grease, and cyanides. Each of these needs to be substantially reduced to allow for recycle, reuse, or discharge of the treated effluent.

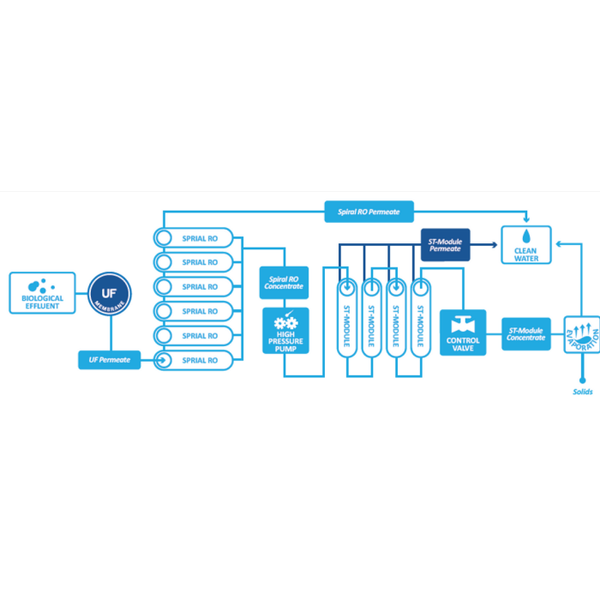

Wastewater produced in the CTX process is characterized by large flow volumes with high organic loading, suspended solids, and dissolved inorganic impurities. This wastewater requires multiple treatment steps. ST+ and ST++ modules are excellent choices to drive concentration up and the cost of evaporation down.

Based on a typical CTX wastewater stream, we’ve estimated the permeate quality following a single stage of ST+ modules.

AquaZoom RO technology is installed in one site operating on CTX wastewater. This installation uses up to 200 of our ST++ modules. We are in the process of getting operating data for inclusion on our website.