- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- 14.5 MW CHP System - HP Hood LLC - Case ...

14.5 MW CHP System - HP Hood LLC - Case Study

For more than 170 years, the name Hood® has been synonymous with fresh, quality dairy products that taste great. Founded in 1846 in Charlestown, Massachusetts, by Harvey Perley Hood, the company has since extended its New England roots, and today Hood is a national company distributing dairy products throughout the United States. In fact, HP Hood LLC is now one of the country’s largest branded food and beverage companies with 13 manufacturing plants throughout the United States. Their facilities require systems that provide precise temperature and pressure control and reliable power for its operations. To reduce operating costs, HP Hood LLC implemented an energy management and cost-reduction system in its Winchester, Virginia, facility which included a 14.5 MW CHP plant. The CHP system powers the dairy plant, ensures reliability, improves energy efficiency, reduces emissions, and reduces costs for the Winchester campus, which manufactures and packages fluid dairy and non-dairy aseptic, Ultra High Temperature (UHT), and Extended Shelf Life (ESL) beverages.

- LOCATION: Winchester, Virginia

- MARKET SECTOR: Food Processing

- FACILITY PEAK LOAD: 15 Megawatts (MW)

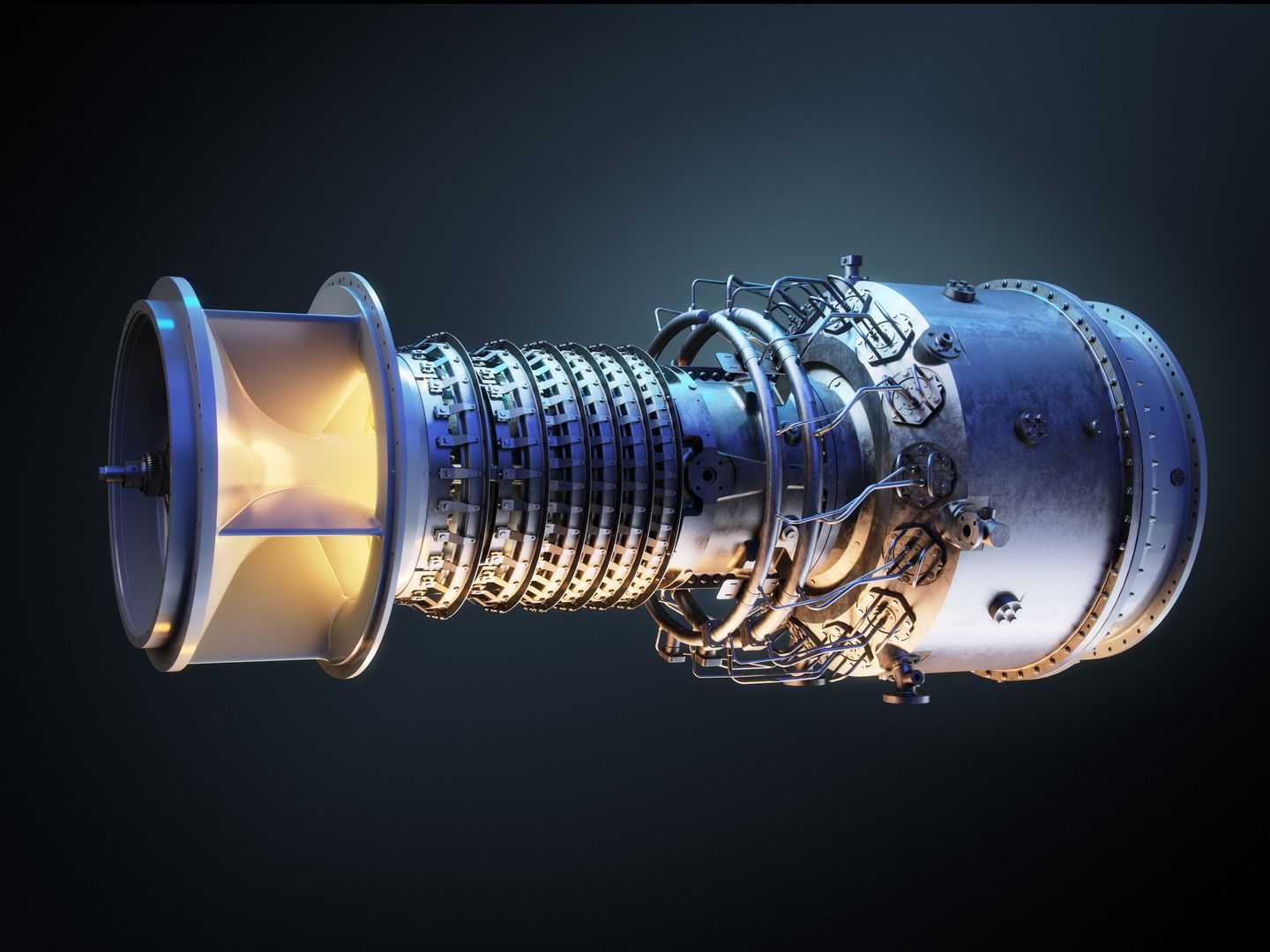

- EQUIPMENT: 14.5 MW gas turbine, HRSG, and absorption chiller

- FUEL: Natural gas

- USE OF THERMAL ENERGY: Steam for building, process heat, process cooling, and anerobic digestion

- CHP SYSTEM COST: $24,000,000

- ENERGY INTENSITY: Improved energy intensity (MMBtu consumed per product unit) by 24%

- ENVIRONMENTAL BENEFITS: Reduced total CO2 emissions by 30%

- YEARLY ENERGY SAVINGS: Gross cost savings are 28-30%

- PAYBACK PERIOD: HP Hood realized instant savings through a PPA with ZF Energy Development

- CHP IN OPERATION SINCE: 2015