InduMar Products, Inc.

Boreshield ARO II Protects Brazilian Gas Pipeline During HDD Installation - Case Study

Dec. 20, 2025

Courtesy ofInduMar Products, Inc.

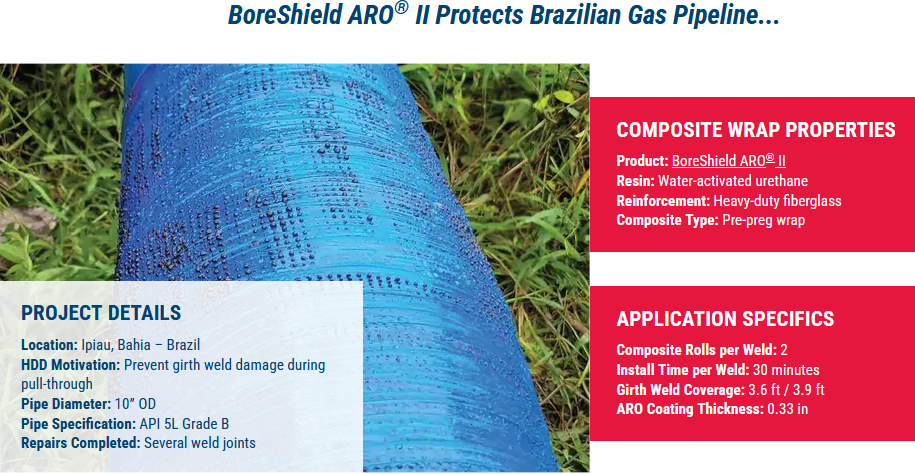

In February 2025, Bahia Gas completed a pipeline protection project in Ipiau, Brazil, to address coating damage at HDD transition points. PVC sleeves secured with shrink wrap had been previously installed by a different contractor and had failed to protect the 10" API 5L Gr. B pipeline during pull-through operations. To enhance wear resistance and protect the 3LPE coating system at girth welds, BoreShield ARO® II outerwraps were applied. The solution provided rapid installation and superior abrasion resistance, and eliminated the need for rework.

Most popular related searches

HDD CHALLENGES

- Horizontal Directional Drilling (HDD) installations in midstream gas projects subject pipelines to severe abrasion, particularly at girth welds.

- Conventional protective systems, such as PVC sleeves and shrink sleeves, often fail under mechanical stress and soil load encountered during pull-through.

- Inadequate wear protection at weld joints increases the likelihood of corrosion and asset degradation should the primary coating be damaged during HDD installation.

- High humidity and aggressive soil chemistries in tropical regions, such as Bahia, exacerbate coating failures and reduce the effective lifespan of traditional sleeve systems.

PROJECT NEEDS

- Protect girth welds from abrasion during HDD pull-through.

- Remediate failed PVC sleeves and shrink wrap systems.

- Allow for fast installation without the need for special tools or equipment.

- Provide durable wear resistance for 3LPE-coated HDD pipe.