- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- Caterpillar Aurora - 15 MW CHP System - ...

Caterpillar Aurora - 15 MW CHP System - Case Study

Quick Facts

LOCATION: Aurora, Illinois

MARKET SECTOR: Manufacturing

FACILITY SIZE: 4,200,000 sq. ft.

NUMBER OF WORKERS: ~2,700

CHP GENERATING CAPACITY: 15 Megawatts

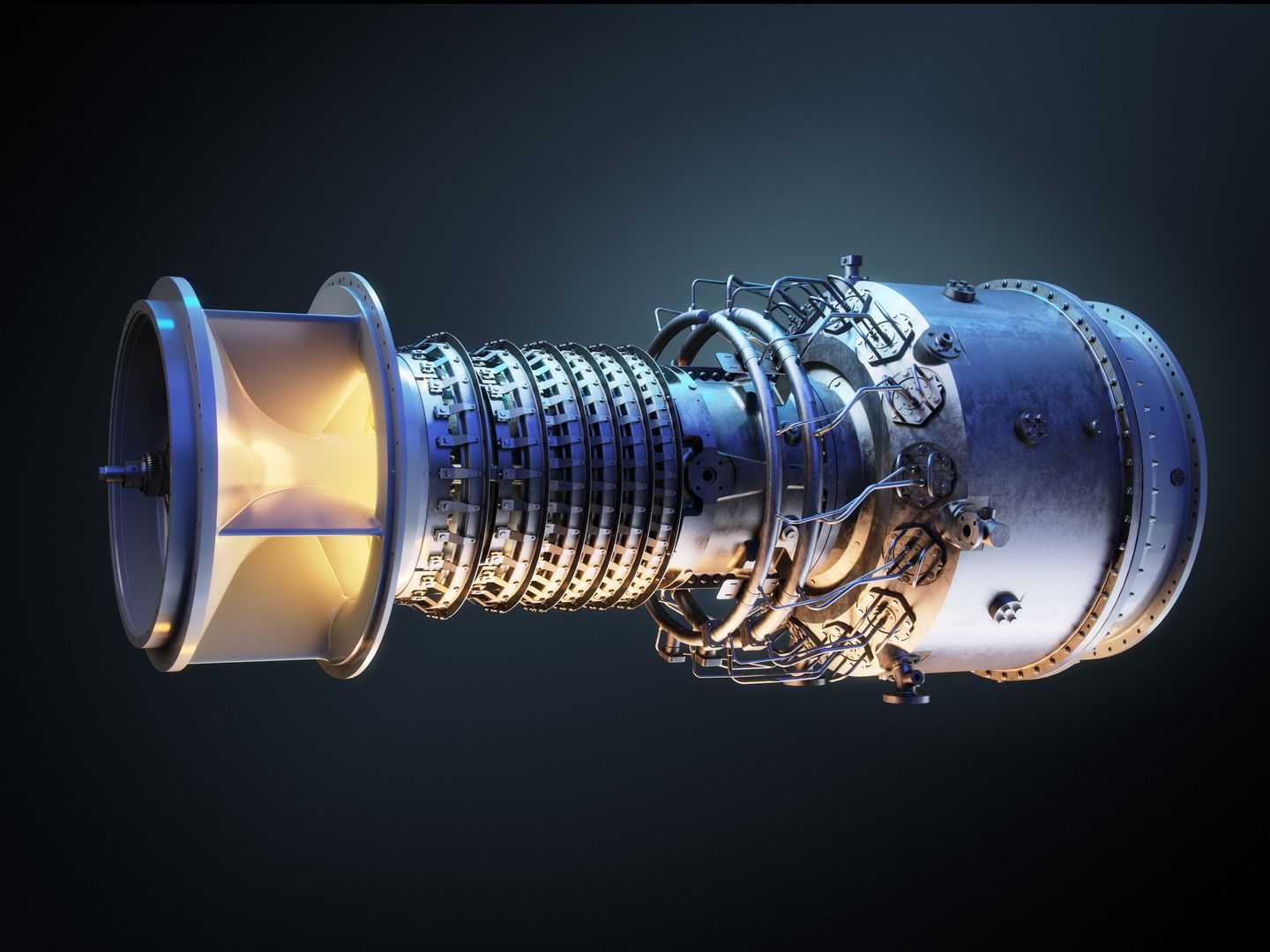

PRIME MOVERS: Two Solar Taurus 70 turbines

INLET COOLING: Wetted-media evaporative cooling for preventing loss of capacity and efficiency during hot weather

FUEL: Natural Gas

HEAT RECOVERY EQUIPMENT:

(2) Deltak Heat Recovery Steam

Generators (HRSGs)

HEAT RECOVERY RATE: Up to 290,000 lbs/hr

USE OF THERMAL ENERGY: Space & process heating

PAYBACK: ~4 Years

BEGAN OPERATION: August 2000

Project Overview

Caterpillar’s Aurora, Illinois plant is a 350 acre site that houses their Wheel Loaders & Extraction Division. The plant has a maximum electrical demand of 16 MW and a maximum steam load of 200,000 lbs/hr. In August 2000, a turnkey combined heat and power (CHP) system was installed by Solar Turbines Inc., a subsidiary of Caterpillar, which included engineering, procurement, construction, project management and commissioning. Today, Solar Turbines continues to operate and maintain the CHP system. The main installation consists of two packaged Solar TaurusTM gas turbine generator sets and two Deltak heat recovery steam generators (HRSGs) for generating steam at 125 psig. The Taurus gas turbine generator sets are rated at 7.5 MW each, giving a total CHP system capacity of 15 MW. Each turbine is capable of producing 30,000 lbs/hr of steam without duct firing of HRSG. With duct firing, steam production can be increased up to 145,000 lbs/hr.

Reasons for CHP

The Aurora plant was an excellent candidate for CHP due to its large and coincident thermal and electrical loads. The project was financially attractive due to the imminent need to upgrade the plant’s aging systems. The physical plant had old coal boilers with a baghouse and coal elevators. Significant expenses were needed ($6-9 million) to upgrade the coal boilers and related equipment. The existing equipment had obsolete parts and controls, and was generally inefficient and unreliable. Furthermore, the high emissions of NOX, SOX, CO2, and CO from the coal plant were an environmental concern.

In addition to the aging physical plant, electricity deregulation in Illinois offered Caterpillar a choice - stay with the incumbent utility, switch to an alternative retail electric supplier, or generate some or all of its own power.