- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- Eastern Michigan University 7.8 MW CHP ...

Eastern Michigan University 7.8 MW CHP Upgrade - Case Study

Eastern Michigan University (EMU) is located in Ypsilanti, Michigan, approximately 35 miles west of Detroit and 8 miles east of Ann Arbor. It was founded in 1849 as a small teachers college and today has grown into a major public learning and research institution with over 21,000 students. EMU historically has been a leader in energy efficiency and sustainability. In 1987, the University invested in a 4.5 MW natural gas turbine CHP system with a heat recovery steam generator (HRSG) capable of providing 56,000 Ibs/hr steam for use in the University`s central heating system. In 2009 the University entered into a multi-year partnership with ENGIE Services U.S. to renovate four residence halls and two dining halls, making the facilities more energy efficient. Upon completion of these facility upgrades, the University again partnered with ENGIE in 2016 to improve the operation, reliability and efficiency of its Central Heating Plant. This meant the replacement of a 64 year old boiler and a 28 year old CHP system with a new 7.8 MW gas combustion turbine CHP system.

- Quick Facts

- Location: Ypsilanti, Michigan

- Market Sector: Colleges and Universities

- CHP Generation Capacity: 7.8 MW

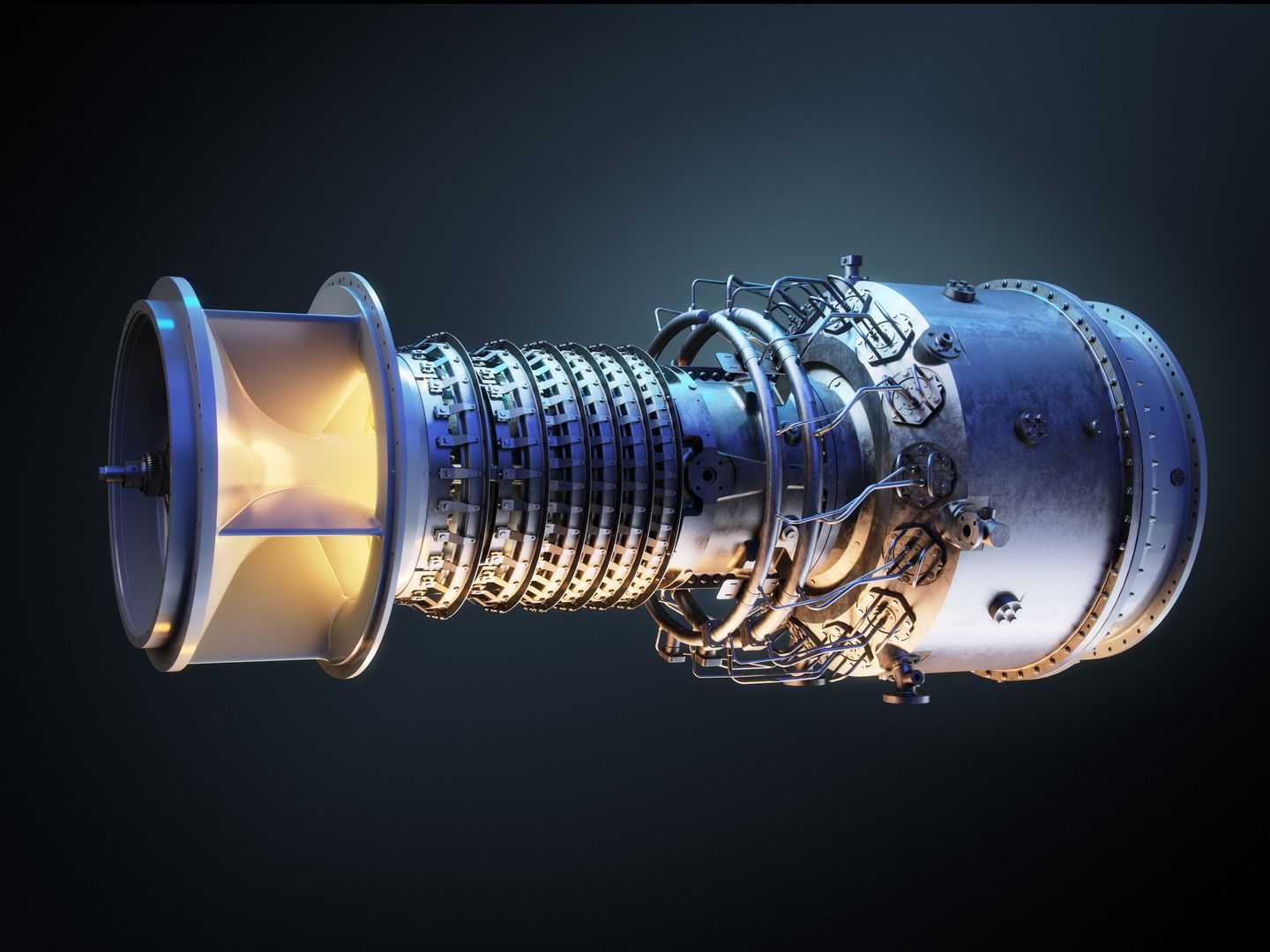

- Prime Mover: Solar Turbines Taurus 70 combustion turbine with SoLoNOx low NOx combustor

- CHP Fuel Source: Natural gas

- CHP Heat Recovery: HRSG that produces up to 90 MMBtu steam with duct firing (135psi steam)

- Gas Compression: Includes two reciprocating compressors (redundancy) that boosts natural gas to the required 225psi turbine inlet pressure.

- Est. Annual Cost Savings: $2.8M

- Project Payback: Estimated at 7 years

- Began Operation: February, 2018

- Est. Annual CO2 Global Emission Reduction: Offsets approx. 48,800 metric tons, equivalent to 10,700 passenger vehicles removed from the road

Technology Options

Before EMU made the decision to invest in their new CHP system, a number of different technology options were analyzed. One option was to replace the aging CHP system with energy efficient steam boilers and return to purchasing all required electricity from DTE Electric, the local electric utility. This option was rejected on an economic basis, based on a minimal return-on-investment (ROD calculation.

A second option included the design and installation of a fuel cell system. Although the electric conversion efficiency of the fuel cell system was relatively high, the system had limited thermal heat recovery and required a large physical footprint. In addition the system had both a high first cost and high estimated maintenance cost.

The third and eventually selected option explored the use of a natural gas turbine/generator set with heat recovery. EMU and ENGIE evaluated several turbine and heat recovery system combinations. The winning design most suitable to the University`s needs, was a single Solar Taurus 70 turbine/generator set with a heat recovery steam generator (HRSG). The system is capable of providing 7.8 MW of utility grade electricity along with 90,000 Ibs/hr steam for use in the university`s central heating system. The system provides 93% of the annual electric requirements and 98% of the annual thermal requirements for the 800 acre campus. Any shortfall in electric requirements is provided by DTE Electric, and any shortage in heating requirements is provided by the existing backup steam boilers.