- Home

- Companies

- Global Water & Energy, part of Ekopak ...

- Articles

- GWE’s biogas in a balloon continuous ...

GWE’s biogas in a balloon continuous to boost both environmental and business performance at NH Foods Australia facility

A far-sighted green energy initiative made by the leading meat processor NH Foods Australia at their Oakey Beef Exports facility, is paying handsome dividends in terms of cleaner wastewater effluent, as well as a reduced carbon footprint and lower energy costs.

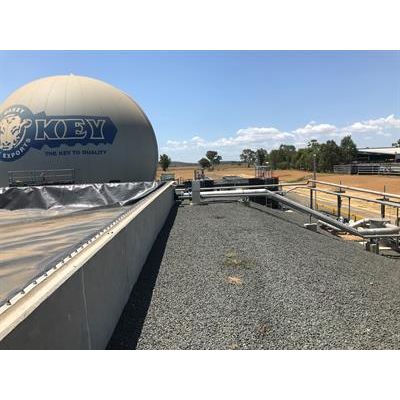

The Global Water & Energy (GWE) COHRAL™ (Covered High-Rate Anaerobic Lagoon) system was installed at Oakey by Australian environmental engineering and green energy authority CST Wastewater Solutions, which recently inspected the plant, as it approaches its landmark fifth year of service in southern Queensland.

CST found that the clean, compact, and robust plant is in outstanding condition, having required only routine maintenance over that time, as it continuously produces 3000-4000 m3 of biogas a day, depending on plant throughput.

NH Foods – proof that profitability and sustainable development go hand in hand

The GWE anaerobic digestion plant produces green energy in the form of biogas from Oakey Beef Export’s wastewater streams, replacing millions of dollars’ worth of natural gas over its operating life, in Queensland’s Darling Downs region.

The generated biogas is directly used in the plant’s existing boiler. This leads to a reduction in fossil fuel use and sharpened cost-efficiencies at a time they are most needed, due to the current Australia-wide drought.

Instead of effluent being managed in the energy-intensive and space-consuming aerated lagoons used by many foods and beverage businesses – with all of their associated environmental, OH&S hazards, water and odor issues – waste at Oakey is converted to biogas by a clean, green and reliable anaerobic digestion process.

With a wide range of various anaerobic technologies in the portfolio, GWE is capable of providing custom biogas-generating plant to many food an beverage processing plants generating waste streams high in organic content.

Benefits of COHRAL™ application

The GWE COHRAL™ plant involved, occupies just half the footprint of comparable covered anaerobic lagoons and much smaller space than that required by typical energy-hungry and often-odorous, open aerated lagoons that are in service in similar applications globally.

The necessary pretreatment before the COHRAL™ system also leads to superior recoveries of valuable protein and fats which would typically end up in the wastewater.

This could be classified as an indirect benefit to the bottom line, as well as increasing treatment system reliability by isolating such problematic waste from the high-performance wastewater treatment plant (WWTP).

By transforming a wastewater treatment and disposal problem into an ongoing productive asset, the plant has achieved a rare business and environmental ideal of overall cleaner, greener factory performance, via stable, predictable waste treatment and profitable supplies of biogas.

“The wind doesn’t need to blow, and the sun doesn’t need to shine, to produce this green energy – which gives it both advantages over, as well as complementing the many excellent solar and wind energy systems suited to other projects. Ultimately, the plant pays for itself with biogas then go on to produce virtually free energy for many years after that,” said Mr. Bambridge.

“Right now, the Oakey plant is delivering cost-efficiency benefits at a time when they are most needed, when the plant has to operate efficiently while coping with herd reductions resulting from the drought. Its success is clearly demonstrating the value in service of anaerobic technologies that are widely applicable to the food, beverage and primary processing industry.”

The NP Foods plant in Oakey is designed to produce biogas (primarily methane) which is stored for use in a 6000m3 capacity, flexible, PVC-coated polyester storage balloon from which it is drawn to fuel the boiler, as needed.

The WWTP plant simultaneously delivers high quality treated wastewater by biologically removing organic content, ensuring minimal impact on nearby waters and the environment generally.

The GWE technology involved removes 80-90 percent of the organic contaminations, minimizing the need for final polishing. Gas-tight construction of the treatment plant maximizes biogas capture, ensuring no methane escapes into the atmosphere, also contributing to the reduction of odors from the overall WWTP.

The clean operating environment of the COHRALTM plant and its near garden-like area show NH Group dedication for safety and hygiene at every stage of their production, even disposal of post-production sewage.

“Oakey Beef Exports is one of the most modern meat works in Australia and one of the country’s largest beef export plants. Operating in a global market, as a premium exporter to 34 countries, means its manufacturing processes need to be respectful, sustainable and efficient,” says Mr. Bambridge.

The GWE COHRAL™ technology at Oakey is another excellent example of the widely-proven GWE anaerobic technologies used in more than 400 plants worldwide in a wide variety of industries.

Contact GWE today to know more how you can benefit from the application of anaerobic industrial wastewater treatment technologies.