Heat Exchanger System Articles & Analysis: Older

30 articles found

The efficiency with which the reactor manages and utilizes heat can significantly impact the yield and quality of these byproducts, making it an essential consideration in the design and operation of pyrolysis systems. ...

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. ...

Background The Ball-Tech Energy Ltd automatic heat exchanger tube cleaning system type BMS – 8" system was installed and tested on 1996 on an underground refrigeration machine. The refrigeration plant was operated for two periods of two months with and without the cleaning system in use. Results of the ...

While heat treatment is important in ensuring the safety of apple juice through pasteurisation or sterilisation, for some products heat plays an important role in the production process itself. The physical and chemical properties must be considered when they are juiced and processed. Sugar content is typically around 11%, while dry matters vary between 13 and 20 % depending on variety and ...

There are numerous uses for heat exchangers in breweries, from cooling, pasteurising and fermenting products, through to efficiently dealing with waste streams such as yeast slurry. Compared to other methods of heating, heat exchangers can be much more energy efficient, providing both environmental and economic benefits. One of the first uses of heat exchangers in brewing is for rapidly cooling ...

Heat exchangers which employ heat recovery or regeneration should not be confused with ‘regenerative heat exchangers,’ which are a specific type of heat exchanger. What we mean by heat regeneration at HRS is the recovery of as much surplus heat (or cooling capacity) as possible after the primary function of the heat exchanger has been performed. This can then be reused to either ...

Heat exchanger used in a hot water supply system The figure below shows the heat supply system using a central heat exchanger (H-Ex). Exhaust gases enter the heat exchanger at Te,g and exit at Ts,g. Their heat is used to ...

Air conditioning, power plants, petroleum refineries, combustion engines and more – all of these have a vitally important part in common. Not sure what that is? That’s fine, what they have in common is a device called a heat exchanger. Now believe it or not, you are probably quite familiar with one heat exchanger, but know it under a different name; it’s the radiator in your ...

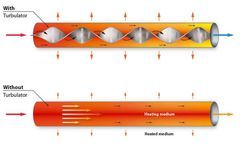

Introduction Heat transfer enhancement in all types of heat exchanger systems is of great significance for the cooling and heating industry. ...

Here are ten of the most common mistakes that can occur as a result of poorly-specified or badly-installed heat exchanger systems – and how you can avoid ...

Design and construction plays a key role in achieving this, and the heat exchangers used for processes such as pasteurisation and sterilisation are no exception. There are three main elements to preventing contamination occurring in tubular heat exchangers: production quality, system design, and ...

When operating in exceptionally challenging conditions, or handling difficult materials such as sewage and wastewater sludges, even the best designed heat exchangers will be susceptible to fouling. Understanding the different types of fouling and what causes them will help engineers and operators pick the best type of heat exchanger for their particular application and keep it running in optimum ...

Right now, we are in the middle of summer, so heat is probably on your mind. Heat exchangers exist in all sorts of applications. Your heating system might use a metal heat exchanger to transfer heat. This could mean it’s made of carbon and stainless steel, ...

Production efficiency – Recently, my nearby colleague and I compared our electricity and heating bills for the year 2018. My new house with DACS ventilation and AddAir heat exchangers versus his three-year-old house with side wall inlets and roof mounted exhausts and heat exchangers (the entire ...

ByDACS A/S

Founded in the UK in 1988, TTIL has become the go-to fouling removal service provider and often a lifeline for oil and gas companies, including global majors, experiencing a costly decrease in performance due to fouling build-up within static fired and unfired heat transfer units. The Essex-born company, now employing 28 members of staff, has delivered unprecedented energy ...

Most heat exchangers have tube diameters of 5/8 inch, 3/4 inch or 1 inch. ...

SR received a $2 million award to demonstrate its thermochemical energy storage system (TCES) technology for a supercritical CO2 cycle, which sees refined and tailored reinforced calcium oxide undergo a reversible carbonation reaction in a parallel-plate heat exchanger reactor. ...

The Kenics heat exchanger provided more efficient, cost-effective processing of the chemical. ...

Ultimately, the customer choose to contract with Catalytic Products International for the design and installation of a RTO Waste Heat Recovery System. The Heat Recovery System incorporated our specialized heat exchanger package and control system that is designed to return ...

When the installations were completed in 2007 the project was the largest district heating project to date in China. Under the contract, ABB provided 96.1 km of pre-insulated pipes, 378 frequency converters, 252 secondary network circulation pumps, 252 heat exchangers, 2000 instruments that are used to supervise and control the network and ...