Of Biochar Pyrolysis Production Articles & Analysis: This-Year

16 articles found

Appropriate pretreatment not only improves carbonization efficiency but also helps enhance the quality and yield of the final biochar product. As a carbonization equipment manufacturer, we will introduce common pretreatment steps for rice husk carbonization to help you better prepare for carbonization and achieve higher production efficiency. 1. ...

The utilization of biochar pyrolysis equipment allows for controlled production, ensuring consistent quality and scalability. ...

In recent years, the conversation around climate change mitigation has shifted from simply reducing emissions to actively removing carbon dioxide from the atmosphere. Among the emerging solutions, biochar production through biomass carbonization is gaining attention as both a waste management tool and a carbon sequestration strategy. ...

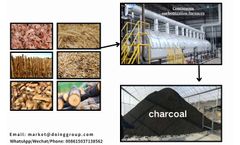

As the world searches for sustainable solutions to address climate change and soil degradation, biochar has emerged as a powerful tool. Produced through the carbonization of agricultural waste such as rice husks, wood chips, and crop residues, biochar offers both environmental and economic advantages. The growing availability of modern biochar production machines makes this solution increasingly ...

The best feedstock for biochar production depends on its availability, carbon content, and ease of processing. ...

High-quality machine-made charcoal offers a long burn time, high calorific value, and is smokeless and odorless. Charcoal, especially through biochar production and soil application, can act as a carbon sink and reduce atmospheric CO2, playing a role in achieving carbon neutrality. ...

At the forefront of this evolution is the biomass pyrolysis plant for sale, an industrial solution engineered to convert agricultural residues, forestry waste, and other organic materials into biochar—a stable, porous solid additive. ...

For companies ready to take advantage of this growth opportunity, efficient and sustainable production scale is essential. Biochar is a solid product formed by heating biomass in the absence of oxygen through pyrolysis technology. ...

The abundance of coconut shells makes them an ideal raw material for biochar production, offering a low-cost input for businesses in the renewable energy and agricultural sectors.The pyrolysis process, which involves heating organic material in the absence of oxygen, breaks down the coconut shells into biochar, gas, and oil. ...

Start Your Large - Scale Biochar Pyrolysis Use High Initial Costs: Setting up large - scale biochar pyrolysis equipment requires significant capital investment. ...

The versatility of biochar, combined with the increasing demand for eco-friendly solutions, makes investing in biochar production a profitable venture. ...

Biochar is a carbon-rich material produced by heating biomass (e.g., agricultural waste, forestry residues, and organic matter) in a low-oxygen environment (biochar production equipment) through a process called pyrolysis. ...

Biochar production has become an essential part of the sustainable waste management and renewable energy sectors. ...

In this process, organic materials are heated in a biochar pyrolysis equipment in the absence of oxygen, causing them to break down into solid, liquid, and gaseous by-products. ...

Biochar Yield: The presence of lignin in biomass typically increases the production of biochar, as lignin is more resistant to decomposition. ...

By using a straw charcoal machine, farmers can effectively eliminate the need for open burning while simultaneously creating a valuable byproduct. Biochar produced through pyrolysis can be used as a soil amendment to improve soil fertility, enhance water retention, and reduce the need for chemical fertilizers. ...