- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- Solvay Specialty Polymers - 8 MW CHP ...

Solvay Specialty Polymers - 8 MW CHP System - Case Study

Quick Facts

LOCATION: Marietta, Ohio

MARKET SECTOR: Chemical

CHP GENERATING CAPACITY: 8 MW

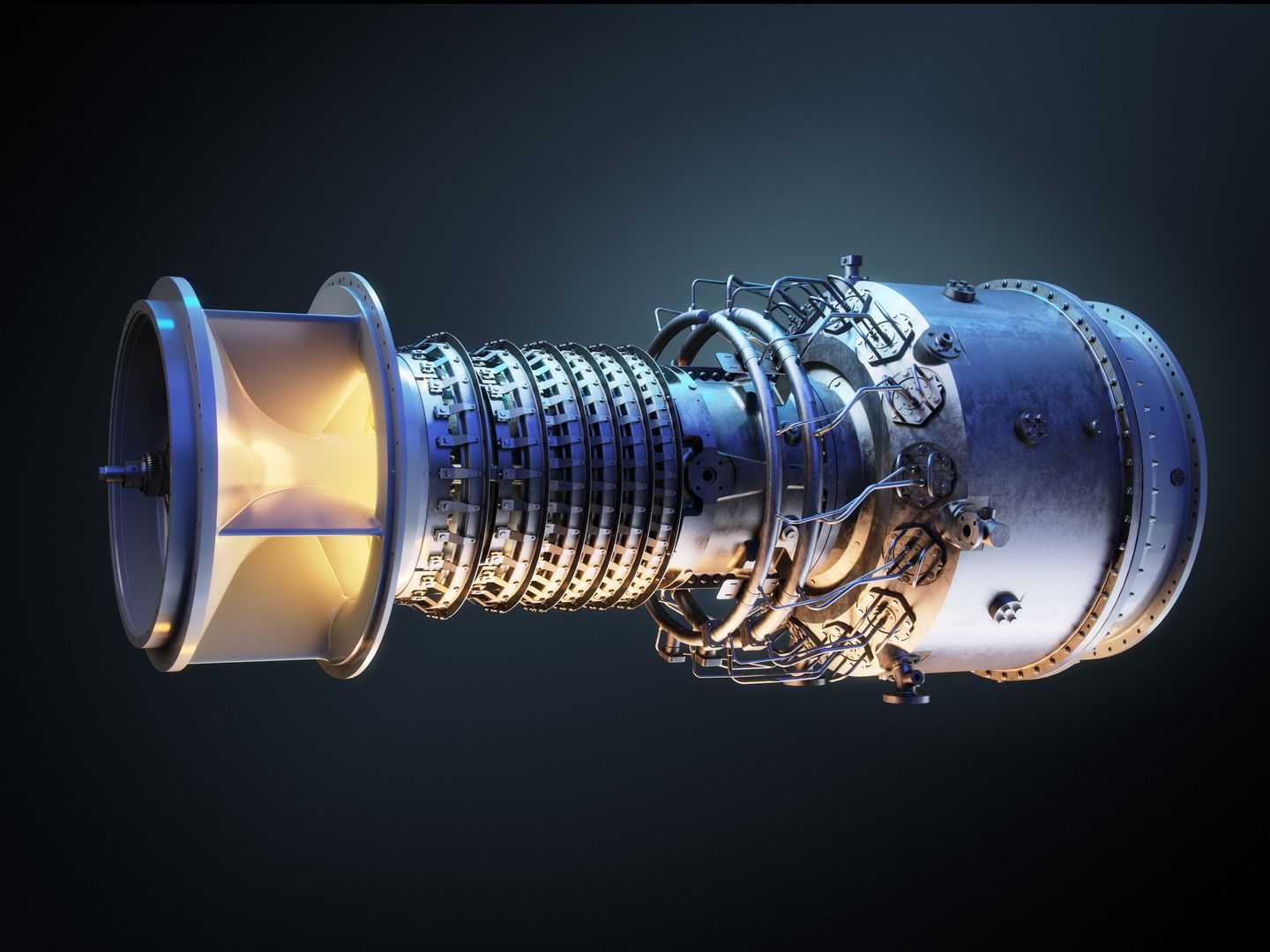

PRIME MOVER: Solar Taurus 70 gas turbine

FUEL: Natural Gas

HEAT RECOVERY EQUIPMENT:

150,000 lb/hr HRSG with fresh air firing capability

Two 80,000 lb/hr package boilers

HEAT RECOVERY RATE: Up to 150,000 lb/hr of 300 psig process steam

USE OF THERMAL ENERGY: Process heating

ENVIRONMENTAL CONTROLS: Low NOx burners and SCR

TOTAL PROJECT COST: $35 million

BEGAN OPERATION: 2015

Project Overview

The DTE Marietta/Solvay Specialty Polymers project in Marietta, Ohio - designed, built, owned, operated, and maintained by DTE Energy Services – began operation in February 2015. The combined heat and power (CHP) facility was developed to meet the steam and power generation requirements for the Solvay Specialty Polymers specialty plastics manufacturing plant. The project provides approximately 8 MW of power generation and up to 150,000 lb/hr of 300 psig process steam to Solvay under a long-term agreement. The steam supplied to Solvay also serves the neighboring Americas Styrenics facility. DTE Energy Services has operations and maintenance responsibility for the substation that serves both chemical facilities. The CHP system provides 100% of Solvay’s steam needs and about 97% of its electrical load. Over the life of the 20-year agreement with DTE Energy Services, the net present value of Solvay’s utility savings will exceed its costs by an estimated $6 million.

History of Project

Solvay Specialty Polymers is a 24/7 operation that employs more than 300 people in the manufacturing of various specialty plastic products, including plumbing fixtures, water filtration media, and cell phone components. In 2010, Solvay lost its source of steam for its plant when American Municipal Power shut its Gorsuch Power Plant as part of an environmental settlement with U.S. EPA. Solvay was forced to install a temporary boiler system, but sought a long-term solution.

The company enlisted assistance from AEP’s Energy Efficiency Program in 2013. AEP agreed to pay Solvay 0.5 cents/kWh for 5 years, enabling the utility to count the electric generation from the new CHP system at Solvay towards its state energy efficiency benchmarks. Receiving the incentives helped Solvay with overall plant/project justification. Ultimately, Solvay chose to pursue CHP both to gain greater control of energy reliability and to reduce its energy costs. The company also selected a third party arrangement with DTE Marietta to better focus on its core business and eliminate capital expenditures for utilities.