- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- Tesoro Petroleum - 22-MW CHP System - ...

Tesoro Petroleum - 22-MW CHP System - Case Study

Quick Facts

LOCATION: Salt Lake City, Utah

MARKET SECTOR: Refineries

TOTAL PROJECT COST: $25,000,000

ENERGY BILL IMPACTS: $200,000 in savings plus $300,000 in sales to utility

PAYBACK: 4.2 years

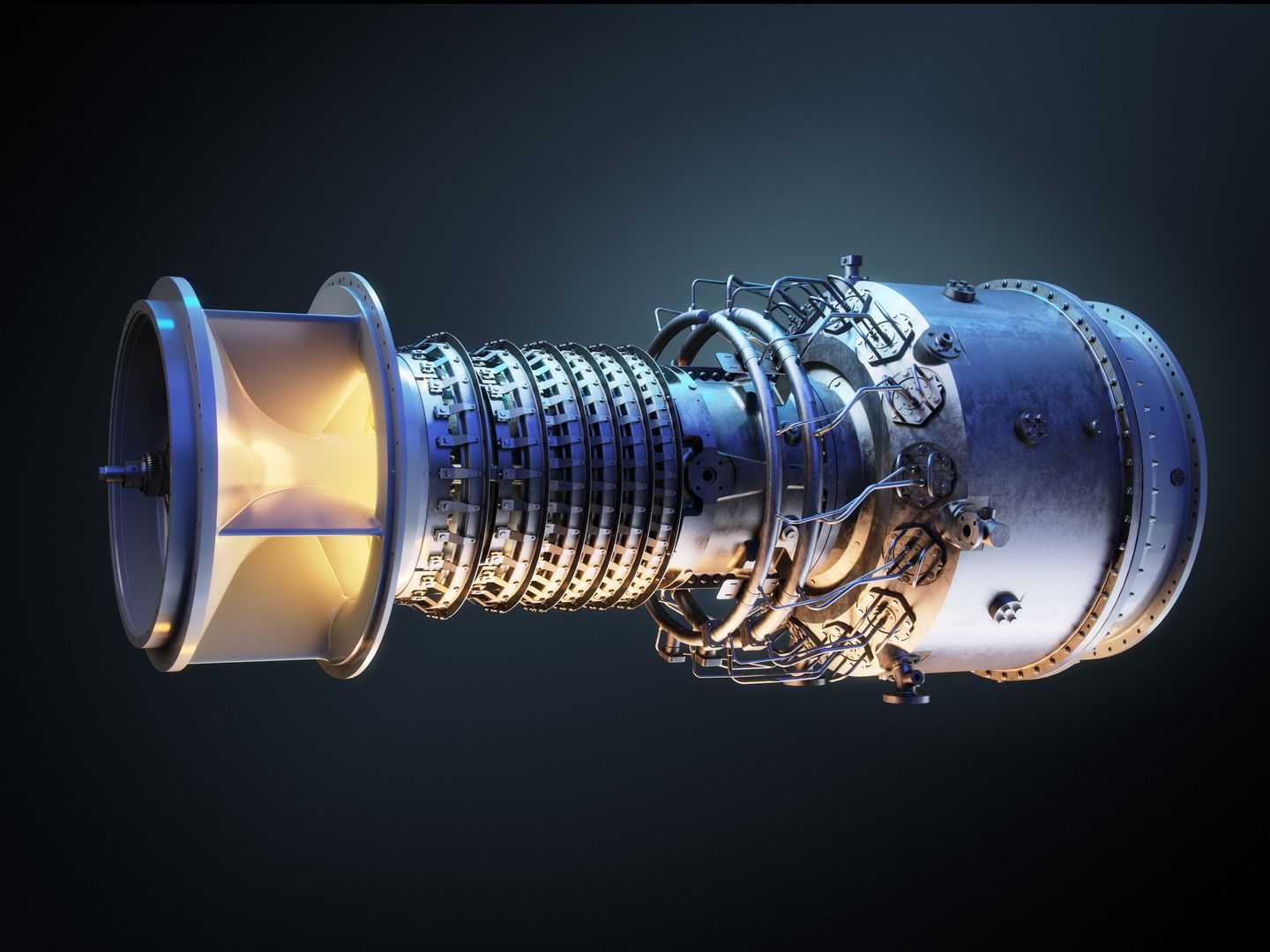

EQUIPMENT: 2 Solar Titan Turbines and 2 Rentech Heat Recovery Steam Generators

FUEL: Natural gas & refinery fuel gas

USE OF THERMAL ENERGY: Process steam

FACILITY SIZE: 145 Acres, 200 employees

FACILITY PEAK LOAD: 15 MW

FACILITY AVERAGE LOAD: 14 MW

CHP IN OPERATION SINCE: 2004

ENVIRONMENTAL BENEFITS: CO2 emissions reduced by more than 85,100 tons/ year

Saving money was the primary reason the Tesoro refinery in Salt Lake City installed a large CHP system. The system nets Tesoro an approximate $500,000 extra per month, in addition to increasing the reliability of the refinery’s electric supply and improving the efficiency and environmental performance of the site.

Site Description

Constructed in 1908 and operated under the UTOCO and Amoco brand names, the Salt Lake City refinery was acquired by San Antonio-based Tesoro Petroleum Corporation in 2001. Tesoro Petroleum Corporation, a Fortune 500 Company, is an independent refiner and marketer of petroleum products and provider of marine logistics services.

The 55,000-barrel per day Salt Lake plant serves the growing hub of the intermountain west. The refinery produces gasoline, diesel fuel, and propane that are sold into the high-growth markets of Utah and Idaho. The refinery also supplies jet fuel to Salt Lake City International Airport and the U.S. Air Force bases in Utah and Idaho.

Reasons for CHP

Two reasons drove Tesoro’s investment in a CHP system: reducing operating costs and improving reliability. Tesoro’s cost to generate electricity depends largely on natural gas prices, and currently the site can produce energy for $35-$40 per megawatt, enabling it to save $200,000 per month on its energy bill. Additionally, it sells $300,000 of energy per month to its utility, making a net improvement to its operations of $500,000 per month.

The CHP system also boosted the site’s reliability. The refinery is located in Rocky Mountain Power’s rapidly expanding load center, where it was challenging for utility investment in transmission infrastructure to keep up with demand, resulting in power outages that were disruptive to the refinery’s 24/7 operations. Other important drivers included the need to replace vintage 1940’s boilers and a desire to be more efficient and environmentally conscious.