- Home

- Companies

- Solar Turbines Incorporated (STI)

- Articles

- Trailblazer Pipeline Compressor Station ...

Trailblazer Pipeline Compressor Station - 4-MW WHP System - Case Study

Quick Facts

LOCATION: Peetz, Colorado

MARKET SECTOR: Oil and Gas, Midstream

ANNUAL ELECTRIC OUTPUT: 27,600 MWh/year

EQUIPMENT: Ormat Organic Rankine Cycle Heat Exchanger

FUEL: Waste heat from turbines drive pipeline compressors

IN OPERATION SINCE: 2009

ENVIRONMENTAL BENEFITS: Site produces virtually nemissions. Nwater is used.

FINANCIAL BENEFIT: $10 million over 20 years

YEARLY ENERGY SAVINGS: $500,000

WHP IN OPERATION SINCE: 2009

NOTE: Qualifies as an eligible energy resource under Colorado’s RES. Provides baseload non-intermittent electricity source for Highline Electricity Association.

Site Description

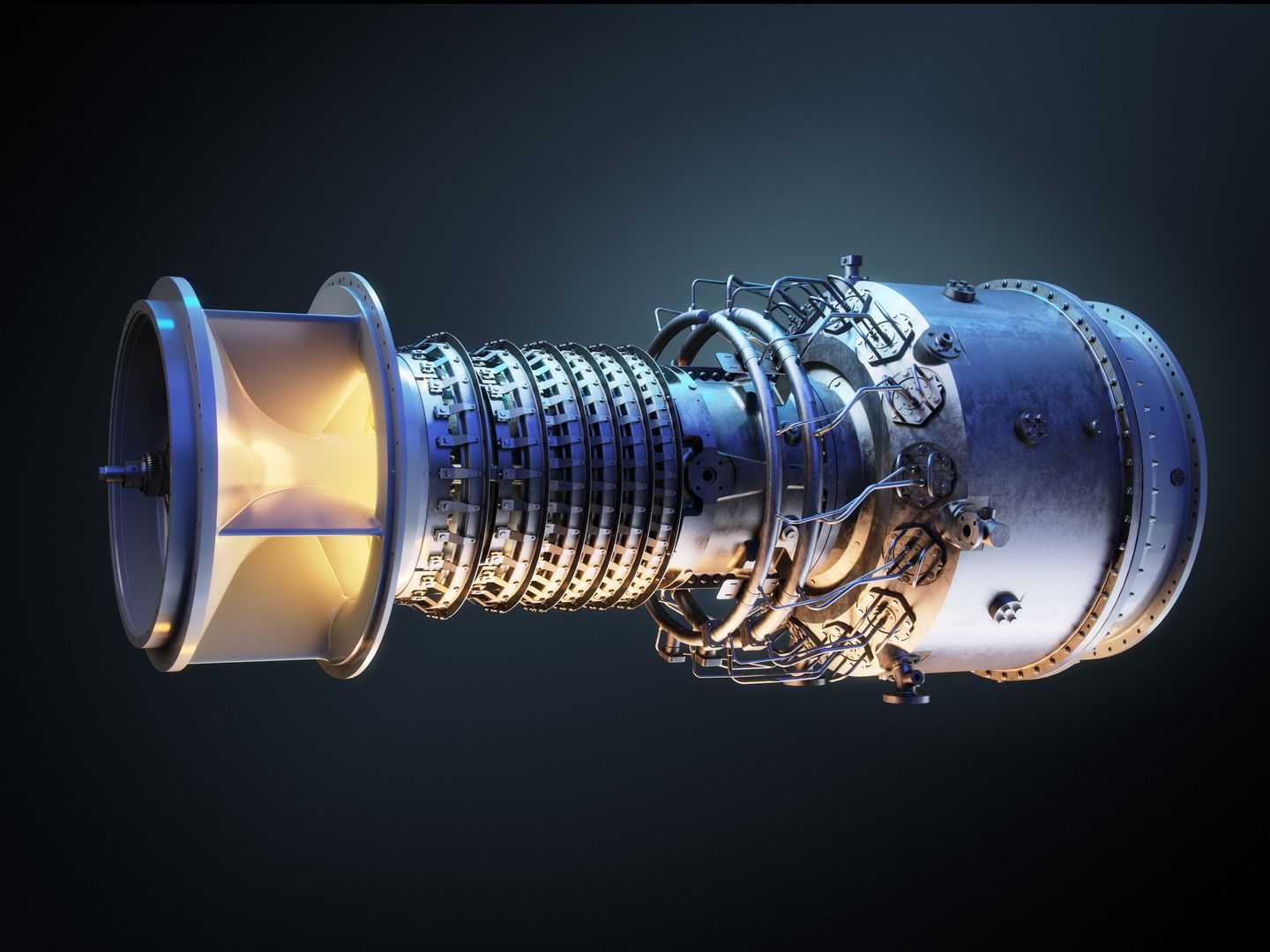

The 436- mile Trailblazer natural gas pipeline transports products through parts of Wyoming, Coloradand Nebraska. Numerous compressor stations maintain the pressure of the gas that travels through the pipeline. Most of these compressor stations are run by turbines that exhaust waste heat.

One compressor station is situated in the service region of Highline Electric Association (HEA). HEA is a member owned rural electric co-op that serves farming and ranching communities in the northeastern corner of Colorado. Rather than venting the exhaust heat tthe atmosphere, it is captured by a waste heat tpower (WHP) CHP energy system and then used tgenerate electricity.

Reasons for CHP

The primary driver for installing the WHP for Highline Electricity Association (HEA) was tprovide cost savings tits members. Added benefits include:

- More than $10 million savings over twenty years

- Qualifies as an eligible energy resource under Colorado’s Renewable Energy Standard (RES)

- Site produces virtually zeremissions