Advanced Ceramic Materials (ACM) products

Other Products

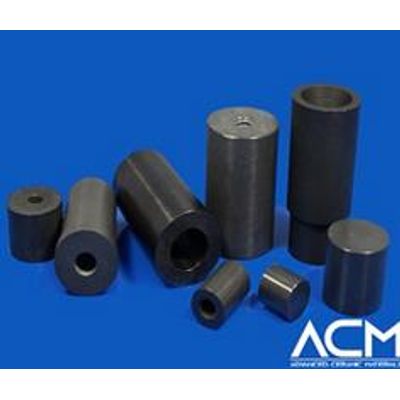

ACM - Model Si3N4 - Silicon Nitride Ceramics

Silicon Nitride is a high-melting-point ceramic material that is extremely hard and relatively chemically inert. The material is prepared by heating powdered silicon between 1300 °C and 1400 °C in an atmosphere of nitrogen. Then the powder of silicon nitride can be sintered to designed shape.

ACM - Model AlN - Aluminum Nitride Ceramics

Aluminum nitride, AlN, is a white ceramic material which has a density of 3.26g/cm3. AlN was first synthesized in 1877, but it was not until the middle of the 1980s that its potential for application in microelectronics was realized. Due to its high thermal conductivity and great electrical insulation, aluminum nitride was used in microelectronic industries. Metallization methods are available to allow aluminum nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Compared with aluminum, which is the traditional technical ceramic material, aluminum nitride has better thermal conductivity and even higher hardness.

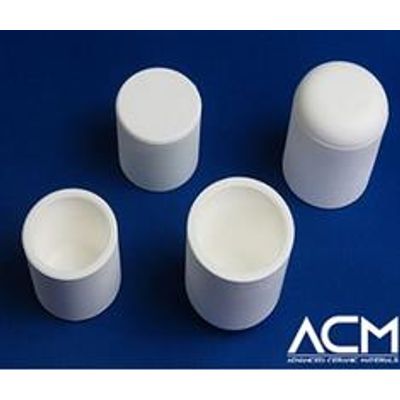

ACM - Model Al2O3 - Alumina Ceramics

Alumina, or aluminum oxide, with a molecular weight of 102, is the major source of aluminum in nature. Alumina has very high melting point, which is 2,072 °C and it is extremely hard. Alumina ceramic is the most common technical ceramic material and a relatively traditional material. High purity alumina ceramics as a fine ceramic material is widely used in a lot of industries.

ACM - Model SiC - Silicon Carbide

Silicon carbide (SiC), also known as carborundum or SiC, is a semiconductor containing silicon and carbon. Since the late 19th century silicon carbide has been an important material for sandpapers, grinding wheels, and cutting tools. More recently, it has found application in refractory linings and heating elements for industrial furnaces, in wear-resistant parts for pumps and rocket engines, and in semiconducting substrates for light-emitting diodes.

Boron Nitride Ceramics

ACM - Pyrolytic Boron Nitride Ceramics (PBN)

Pyrolytic boron nitride is a kind of boron nitride prepared by high temperature pyrolysis reaction by chemical vapor deposition. PBN is an advanced material with excellent properties. It is deposited by the reaction of ammonia and boron halide under high temperature and high vacuum conditions. It can be deposited as PBN sheet material or directly into PBN final products such as tubes, rings or thin-walled containers. Unlike ordinary hot-pressed boron nitride (BN), it does not have to undergo a conventional hot-press sintering process without adding any sintering agen.

ACM - Hot Pressed Boron Nitride Ceramics (HBN)

Hot pressed h-BN, with hardness about 4, is a machinable material. As the forming of this material is not quite easy, it requires about 1900F if it is hot pressed without boron oxide. BN material could withstand higher temperature in vacuum. SAM is contiuoursly cooperate with boron nitride manufacturers and research instituations to enhance the product performance. Our hBN custom parts would have similar performance with Saintg, especially for high temperature applications.