4 products found

Advanced Process Solutions products

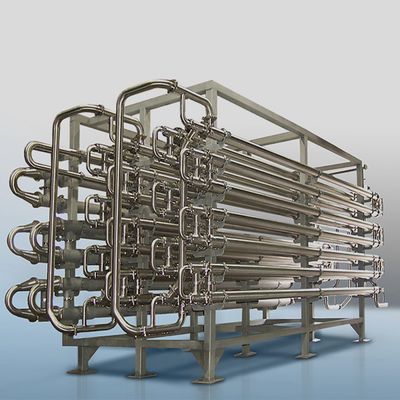

Heat Exchangers

APS - Ultra Coil Heat Exchangers for High-Pressure Liquid Media

The APS Ultra Coil Heat Exchangers are engineered to manage high-pressure liquid media processes via a unique continuous coil design. These exchangers consist of a coiled tube embedded within a media shell, allowing product flow at elevated velocities. This configuration is optimal for processing both thin and viscous substances with or without particulates, necessitating substantial pressure capabilities. The continuous turning of the coil aids in thorough mixing, enhancing the uniform temperature distribution across the media and promoting efficient heat transfer rates. Additionally, it reduces fouling rates due to high velocity. These devices are particularly beneficial in a range of applications including aseptic dairy, sauces, soups, and phase-changing products such as starchy puddings. Featuring a high surface area, a compact design, and compatibility with particulates, the exchangers offer robust performance and efficiency for various industrial uses. They are compliant with USDA standards and hold either ASME or CE certifications.

APS - Ultra-Corrugated Triple-Tube Heat Exchangers for Viscous Products

The Ultra-Corrugated Triple-Tube Heat Exchangers are engineered to efficiently manage the heat transfer of thick, viscous products, either containing or free of particulates. These exchangers feature three concentric tubes that enhance the heat exchange process by allowing the product to flow through the annular space formed between the inner and middle tubes. This design not only doubles the surface area compared to double-tube versions but also ensures optimal heat exchange via a corrugated channel. The exchangers utilize a dual o-ring design for leak detection to prevent cross-contamination between the product and media. Available in semi-welded or fully demountable options, these exchangers support high-pressure operations up to 800 psi, providing flexibility with annular spaces ranging from 1.5 inches to 4 inches. They are perfectly suited for applications requiring direct regeneration heat recovery, delivering cost and space savings while maintaining efficient system configurations.

APS - Ultra-Corrugated Multi-Tube Heat Exchangers for Liquid Media

The Ultra-Corrugated Multi-Tube Heat Exchangers by APS are engineered for the optimal processing of liquids with thin to medium viscosities, including pulpy products. These exchangers feature a unique design comprising multiple parallel tubes within a shell, allowing for efficient heat transfer with minimized pressure drops and enhanced distribution flow due to the innovative 'clean-head' design. These units are particularly suitable for products like juices, nutritional drinks, teas, coffees, and sauces. The corrugated construction minimizes the surface area needed while maximizing heat exchange efficiency through counter-current flow patterns. Constructed from materials chosen for durability and efficiency, they are capable of operating at pressures up to 800 psi. Customizable tube diameters ensure tailored solutions for specific processes, and their design allows for easy cleaning and maintenance, crucial for ensuring food safety in hygienic environments.

APS - Ultra-Corrugated Double-Tube Heat Exchangers for Viscous Product Processing

Ultra-Corrugated Double-Tube Heat Exchangers are fundamental components within the realm of tubular heat exchangers, characterized by their simple yet effective design of a tube within another tube. This configuration, with tube diameters extending up to 4 inches, is particularly suited for handling viscous products, even those that contain particulates. Ideal applications include particulate processing, direct regeneration heat recovery, and scenarios requiring product retention to minimize loss. The heat exchangers are engineered to optimize space and cost efficiency by minimizing heat transfer surface area through ultra corrugations. They accommodate diverse processing needs, with pressure capabilities reaching up to 1200 psi, and support high-efficiency operations by achieving higher Reynolds numbers at reduced flow rates. Customizable in terms of product tube diameters ranging from 1 to 4 inches, these exchangers represent a versatile and efficient solution for enhancing product integrity with low shear impacts.