- Home

- Companies

- AFS Technology

- Products

AFS Technology products

Precalciner Fuel Systems

Rack-Style Suspension Burner

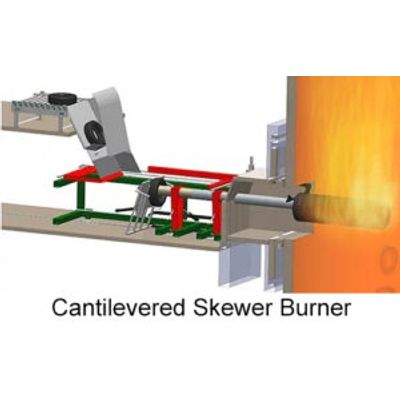

Why choose our patented tire suspension burner systems? Typically, the maximum fuel substitution rate for whole tires fed to the low oxygen backend of a precalciner kiln has been less than 5%. Above this rate localized reducing conditions will likely cause significant sulfur build-up in the kiln riser duct and upper vessels, resulting in production problems. In 2001 – AFS, along with Cementos Melon in Chile, developed the Rack-Style Suspension Burner, which was designed to burn tires in the oxygen rich calciner rather than in low oxygen kiln backend. This was very successful in eliminating the sulfur buildup issues, but the high end feed rate was still limited to about 1 ton per hour per burner. In 2012 – AFS developed (and patented) the Tire Skewer Suspension Burner, which burns tires in the calciner at a rate of 3 to 4 tons per hour per burner without sulfur buildup issues affecting production.

Tire Fuel Equipment

Hook Elevators

Hook elevators are used to elevate whole tires from ground level to the Fuel Injection Device with a minimum ground footprint. AFS has provided Hook Elevators that are over 100 feet high.

Transfer Devices Systems

Transfer Devices are typically used in Whole Tire Derived Fuel systems to: Feed two or more Fuel Injection Devices from a single source, Transfer from one conveyor line to another, Change direction, Change elevation