- Home

- Companies

- Air Liquide

- Services

Air Liquide services

Industry - Processes

Carbonation Services

All over the world, the demand for sparkling drinks is rising. Total soft drink consumption in 2013 was about 188 billion liters. Air Liquide delivers the carbon dioxide (CO₂) that the beverage industry needs to produce the world’s favorite carbonated beverages. We provide beverage makers with the highest quality food grade gases.

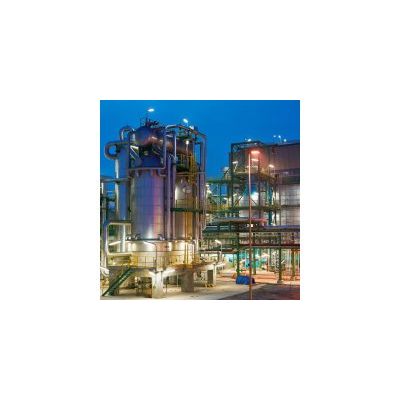

Desulfurization Process Services

Providing gases to the industry in a safe, reliable and efficient way has been the core of our business for over a century. Our expertise in hydrogen, one of the most important gases for industrial applications, stretches back close to 50 years. In the oil and gas industry, hydrogen is mainly used to desulfurize fuels. Air Liquide masters the entire hydrogen chain, from production through to distribution, adapting its solutions to meet increasingly stringent standards.

Gasification Services

Air Liquide supplies industries with innovative and cutting-edge gases, technologies and services to meet their needs. We draw on this know-how to develop coal conversion solutions that both limit the environmental impact of its use as an energy source and create gases essential for the manufacturing of higher added-value products.

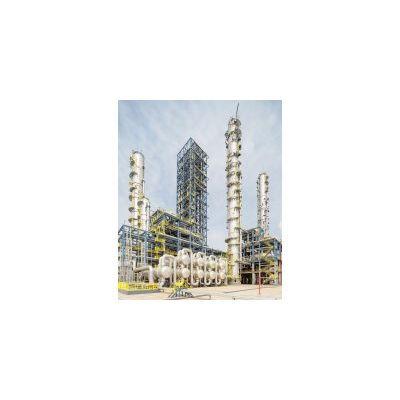

Petrochemical Synthesis

Petrochemicals are used to manufacture thousands of products people use every day. Air Liquide guarantees its customers a safe, reliable and competitive supply of gases required for their production processes so they can focus on their core business.

Engineering & Construction

Acid Gas Cleaning Solutions

As a leading player for the whole syngas value chain, Air Liquide Global E&C Solutions has developed an extensive expertise for acid gas removal with more than a hundred units around the world.

Methanol and Propylene Production

Air Liquide Global E&C Solutions delivers Lurgi methanol technology that has been at the cutting edge of methanol production for over 50 years. We can design our plants that can generate between 100 and 10,000 metric tons of methanol per day – from any feedstock. Our end-to-end systems are tailored to customers’ specifications to ensure highly efficient and cost-effective production.