Airoil Flaregas Pvt. Ltd. products

Flare Systems for Industrial Applications

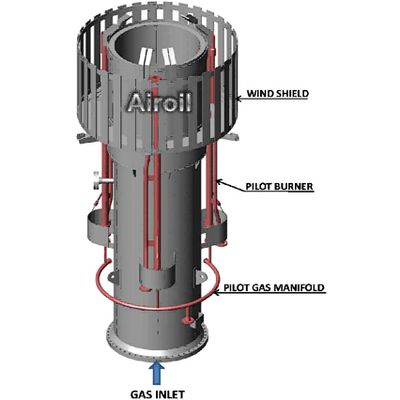

Non-Smokeless Flares

The Non-Smokeless flare tips are used where the environmental condition allows the burning of smoke producing gases. They are also used with gases which produce either no smoke or so little that smoke suppression with steam, air or high pressure gas is not required. Examples of gas used with these tips are Hydrogen, Blast Furnace waste gas, Coke Oven gas, Ammonia, Hydrogen Sulphide and Methane.

Steam Assisted Flares (Smokeless Low Noise)

The Steam Assisted Smokeless flare tips are the most efficient flare tips utilizing external steam nozzles in addition to central steam nozzles and are suitable for sites where a general low noise flare tip is required. The Steam-Assisted Smokeless Flare tips are based on externally mixing steam and air with the gas at the point of exit, utilizing steam injection nozzles. A ring of steam nozzles is located at the top leading edge of the flare tip, inside the wind shield.

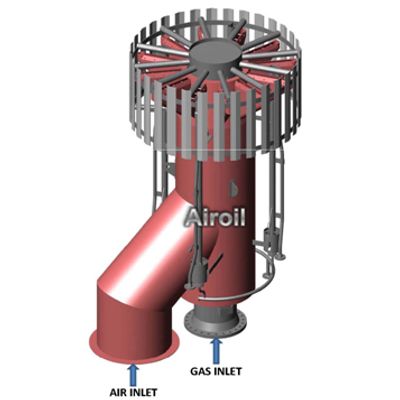

Air Assisted Flares (Forced Air Type Smokeless)

The Air-Assisted Smokeless Flare Tip is used for smokeless combustion applications, where the use of steam is not desired. Smokeless combustion can be obtained even with heavy unsaturated hydrocarbon gases.

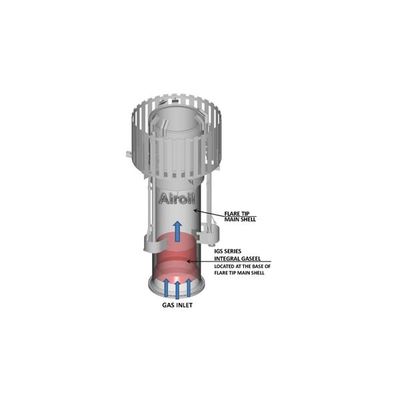

Velocity Seals

The Velocity Seal, located integrally at the base of the flare tip, has been designed to prevent air ingress into the flare system and has a number of advantages over gas inversion seals.

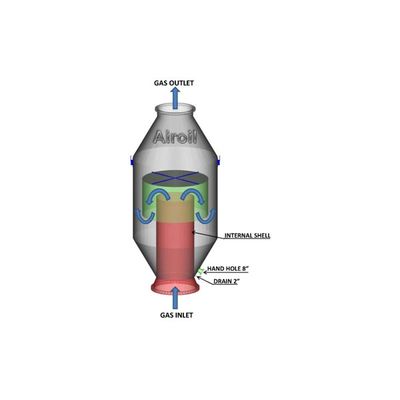

AFG - Molecular Seals

The Molecular Seal is located just below the flare tip and has been designed to prevent air ingress to the flare riser thus preventing the formation of an explosive mixture in the system. The seal is a gas inversion device causing the gas normally flowing in an upward direction to be turned through 180 degrees in the original direction of the flow. In a static condition, gases lighter then air will tend to collect in the upper bend sealing off the stack against the back flow of air. Heavier gases will tend to settle in the lower bend with the same effect. Some wind and atmospheric action will affect these interfaces slightly, and molecular diffusion of the two gases will take place at the interface. In order to counteract these effects a small continuous bleed of gas, dependant on the flare nominal diameter, must be maintained in order to ensure that air does not penetrate the seal.

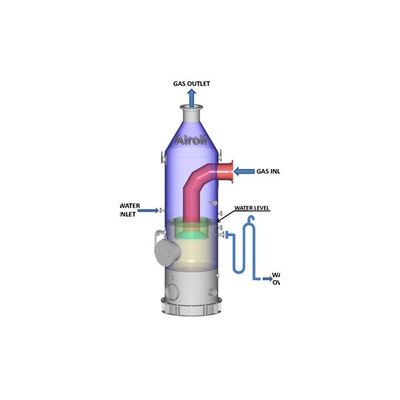

AFG - Liquid Seal Drums

The purpose of a liquid (commonly water) seal drums in a flare gas system in threefold: Performance Features. It operates as a non-return device preventing interaction from the outlet to the inlet of the drum. It operates as an upstream pressure relief valve preventing gas flow from the inlet to the outlet until a particular upstream pressure, frequently predetermined, is reached. It acts as a diversionary unit for:- Ground flare to elevated flare systems; ground flare to ground flare systems; Elevated flare to elevated flare systems; Fuel gas recovery systems to elevated flare.

AFG - Flare Pilots (Flare Ignition Systems)

AFG Combustion’s flare pilots are suitable for use on all types of Elevated Flare Tips, Ground flares and Burn Pits, in the worst weather conditions which may exist off-shore or on-shore, from sub-zero ambient conditions of Antarctica to the sand/wind storms of Middle East and Africa. The pilots have very wide application ranging from standard LPG or natural gas to low BTU gases like bio gas or coke oven gas & also for gases with high hydrogen content. The pilot nozzle is basically a pilot stabilized tunnel burner designed for a high inspiration rate, normally 80% to 85% primary air.

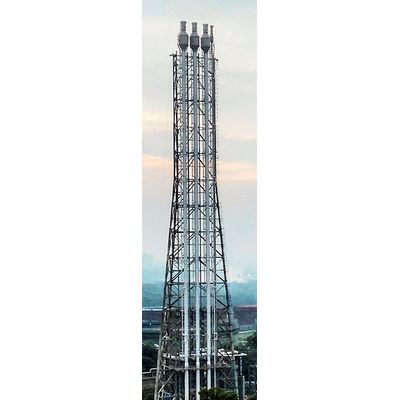

Elevated Staged Flares

Optimization of an Elevated Staged Flare for a Large Refinery or a Gas Plant. In recent years most of the refineries, petrochemicals & gas processing plants are seen to be of larger capacities. Flare system for such plant are required to operate at two extreme flow conditions, one very high flow rates (in excess of 1000 tons per hour or the maximum design capacity rate) as well as at minimum flow conditions (few 100 kg per hour). Further considering environmental issues the flares are expected to perform smokeless operation at certain specified capacities.

Demountable Flares

The Demountable Flare System features a derrick structure with the one or multiple flare risers, mounted in such a way as to permit the lowering of the flare burner to grade for service without the need for an expensive heavy-duty crane. Further the flare burner is lowered to grade without the need of any personnel to climb to the top of the stack. Flare Systems with multiple risers allows for service/replacement on any flare burners, while other Flares operations remain uninterrupted. This means flare maintenance can be performed safely without shutting the flaring. Therefore NO shutdown on upstream operating facility due to shortcoming on one flare. Flare is available permanently, NO process/production outage saving significant time and money.