Antec products

Wind - Rotor Brakes

ANTEC - Rotor Brake System for Wind Turbines

The NHC-900 is a mechanical braking system with a hydraulic release mechanism designed for wind turbine rotors. Featuring a fail-safe design, this brake system utilizes a floating configuration with a self-aligning system to ensure the precise alignment of the brake pads and disc. It delivers up to 55 KN of clamping force and supports both sintered and organic pads, offering ease of replacement. Optional features include pad wear and brake-open detection systems, enhancing operational reliability. ANTEC also provides compatible hydraulic power units tailored for these braking systems to ensure optimal performance.

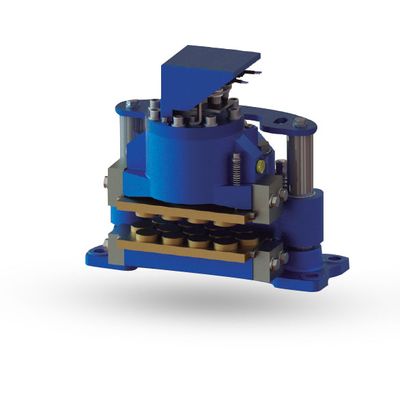

ANTEC - Rotor Brakes for Wind Turbines

The NHC-1400 series provides a robust solution for rotor braking in wind turbines, utilizing a mechanical failsafe system coupled with hydraulic release. Its floating design features a self-aligning mechanism that ensures optimal alignment of the brake pads with the disc. The system is capable of delivering a clamping force of up to 150 KN, adaptable to both sintered and organic brake pads, which can be replaced with ease due to the design's user-friendly features. Advanced options include systems for pad wear and brake-open detection, further enhancing operational reliability. ANTEC also offers compatible hydraulic power units. These features collectively ensure that the NHC-1400 rotor brakes deliver reliable, efficient braking performance essential for modern wind energy applications.

Wind - Yaw Brakes

ANTEC - Hydraulic Yaw Brake for Wind Turbines

The HE-3-90 is a hydraulic yaw brake designed to ensure the precise positioning of wind turbine nacelles, enhancing the efficiency of wind energy generation. It offers a substantial clamping force of up to 420 KN, making it suitable for large-scale applications where stability and control are paramount. The design integrates organic brake pads equipped with advanced wear detectors, available in visual, electrical, or inductive options, facilitating maintenance and longevity. This allows for timely alerts on wear levels, ensuring consistent performance. The floating design of the brake adds to its adaptability, accommodating slight misalignments and thus reducing stress on the components. Such features make it an essential component in modern wind energy systems where reliability and durability are critical.

ANTEC - Hydraulic Yaw Brake for Wind Turbines

The HEG-1-110 is a technologically advanced hydraulic yaw brake, designed for use in wind turbines. This brake system is capable of delivering a clamping force of up to 195 kN, a substantial force that ensures effective control over the yaw motion of wind turbines, which is crucial for optimal turbine orientation and efficiency. The design allows for versatile brake pad options, offering both organic and plastic types to meet specific operational requirements. The robust construction of the HEG-1-110 demonstrates a commitment to reliability and longevity, making it suitable for harsh environmental conditions. This brake is essential for minimizing mechanical wear and optimizing wind energy capture, ensuring the stability and efficiency of wind turbine operations through precise yaw control.

Wind - Rotor Lock

ANTEC - Rotor Lock for Wind Turbines

The Rotor Lock system is designed to provide secure locking capabilities for wind turbine rotors. This mechanism ensures the rotor remains stationary during maintenance or inspection, offering stability and safety for technicians working in high-altitude conditions. By employing precision engineering, the Rotor Lock ensures minimal wear and tear, prolonging the lifespan of the turbine components. It is an essential part of wind turbine design as it allows for seamless integration with existing turbine structures and controls. The system is built to withstand harsh weather conditions, providing reliability and durability in varying climates. The design also complies with international safety standards, ensuring peace of mind when performing mechanical interventions or upgrades on turbine systems.