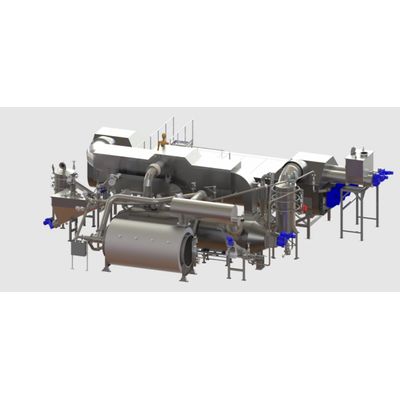

AquaGreen products

Integrated Steam-Drying and Pyrolysis

With AquaGreen’s HECLA® 1,000 plant, you can treat 1,000 metric tons dry matter annually. Doing so, will reduce greenhouse gas emissions by 1,800 ton CO2e, produce 2,000 MWh sustainable energy, and store 500 ton carbon in biochar. The resulting biochar is odorless and has a content of 5-6% plant-accessible phosphorus.

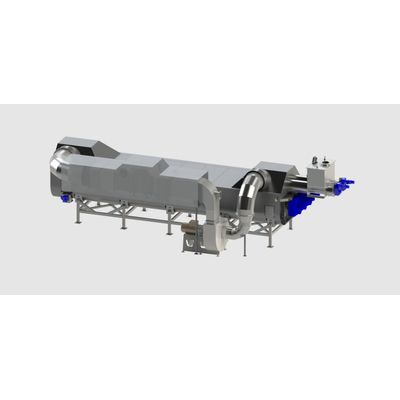

Superheated Steam Biomass Dryer

High-Temperature Slow Biomass Pyrolysis

In the pyrolysis oven, dried biomass is heated to 650°C in an oxygen-free atmosphere. The process takes 20 minutes and eliminates harmful pollutants such as microplastics, medical residues, PFAS, and PAH. The decomposing of organic compounds releases pyrolysis gas, which is combusted in the gasburner. The produced thermal energy is used for both the drying and the pyrolysis. The solid residue formed, biochar, consists of inorganic carbon and mineral ash.