- Home

- Companies

- Belach Bioteknik AB

- Products

Belach Bioteknik AB products

Customized Bioreactors - Fermentors

Dolly - Benchtop Biogas Reactor

The Dolly twin biogas reactor is basically for anaerobic digestion research. It has been developed for liquid-based media with solid matter content up to 10-15%. The standard equipment consists of 2 x 3 to 15L working volume reactors. The reactors are operated automatically providing continuous feeding experiments. Different parameters - temperature, pH- and stirrer can be set and controlled individually by reactor. The BioPhantom expert biogas control system can handle up to ten reactors ideal for parallel studies.

Unique Solutions

Airlift - Bubble Mixed Bioreactor System

Cylindrical glass vessel with draft tube, 1 – 10 L. No moving parts, homogenous conditions. Low shear forces. Temperature control by heat band. Bio-phantom© process control and data log: Temperature, stirring, stirrer power(W), pH, DO (optional), gassing (optional) feed pump (optional), weight (option), gas analyzer (optional).

Einar - Enzymatic Hydrolysis Reactor

Einar hydrolysis reactors are designed for industrial research of enzymatic hydrolysis ofmaterial with both low and high dry matter (up to 40%). Einar user friendly control system provides control for temperature, stirrer speed and power and material pH. Einar reactors are made of acid resistant stainless steel and have a unique tilting system to facilitate mixing of high solid content media. Einar reactors are closed to eliminate evaporation and constructed to be able to provide anaerobic conditions. Einar has been proved a powerful research tool for lignocellulose biomass (wood, straw or other fibrous materials).

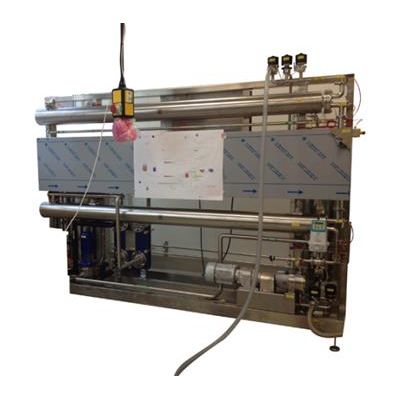

Thermal Heat Treatment Units

Thermal Heat Treatment of biologically active liquid material. Hygienic design, cleaning procedure. Effective heating and cooling by tube or plate heat exchanger. Precision control of material flows and residence time.