Catalytic Industrial Systems products

Industrial Ovens

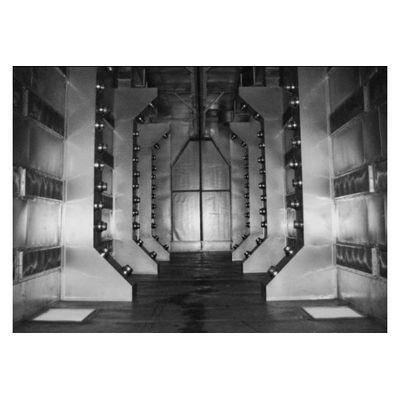

CIS - Infrared Ovens

Process flexibility, long service life and exceptional energy efficiency. The infrared energy is absorbed by the coating on the substrate first without having to wait for the mass of the substrate to reach the curing temperature. This allows the paint to cure more quickly. Gas infrared ovens can cure paints up to 10 times faster than convection which leads to cost savings on energy usage, smaller oven footprint, and increased production.

CIS - Combination Infrared/Convection Ovens

The combination of the technologies delivers enhanced results for powder coaters and facilities that process a variable mix of parts. In a combination oven, the infrared portion of the oven gels, or sets, the powder coating ahead of the convection oven portion. This accelerates the convection soak portion that completes the cure. The infrared energy used in this ramp-up zone also prevents powder loss by gelling the finish before it can be disturbed by the air turbulence in the convection section. It can also help to prevent cross-contamination in facilities that use more than one color of powder.

CIS - Convection Ovens

Manufacturers look to CIS convection ovens as a leading choice for the uniform, efficient cure of solvent and waterborne coatings and adhesives. Convection ovens provide an excellent, highly consistent cure for powder coatings. Convection ovens distribute heat evenly, and are well-suited to parts with complex shapes. Heat energy is moderate, rather than high intensity, so convection is compatible with many substrates.

Heaters

CI - Infrared Heaters

Catalytic Industrial Systems’ (CIS) gas catalytic heaters are safe, efficient, and easy to use. The heaters are offered in multiple sizes, BTU ratings, and configurations to meet varying application requirements. CIS catalytic heaters are available standalone or can be preconfigured onto racks and subassemblies with control systems to simplify installation and operation tasks.

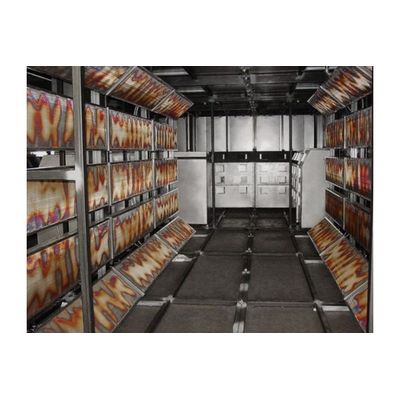

Heaters On Rack

CIS - Mobile Dry Racks

Mobile Dry racks are designed to offer maximum flexibility and mobility. The support structure of the Mobile Dryer Racks offers adjustability in height, depth of reach, and angle to accommodate a variety of shapes and sizes of parts. The MDR can be operated in any open area or be moved inside a paint booth after the paint process has been completed. The heaters can operate with a variety of power supplies ranging from 120VAC to 480VAC. The racks can be ready to operate in as little as 30 minutes. Fuel choices include natural gas or propane with multiple fitting and mounting options.