Charcroft Electronics Ltd products

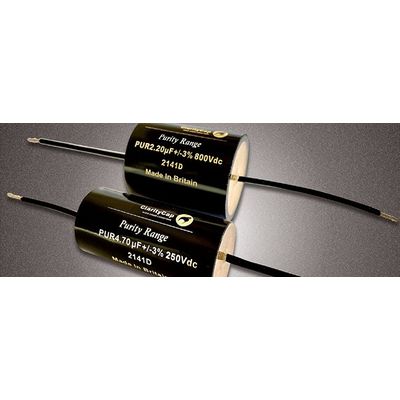

Model PUR - Capacitor

ClarityCap® has taken the science behind audio performance and capacitor technology seriously, for many years. During that time research has been carried out with the leading academic audio research departments and respected audio industry figures, launching new products, only when we are able to contribute tangible benefits. The development of the Purity audio capacitor builds on the ClarityCap® experience of working closely with the specialists in the audio industry, to design and manufacture metallised polypropylene film capacitors tailored for use in audio applications. Taking inspiration from the highly regarded CSA and CMR range, the Purity™ (PUR) range employs the same carefully researched micro-phonics reducing processing parameters. CopperConnect® technology enables designs to employ narrower films for reduced capacitor ESR without introducing the corollary increase in end connection impedance.

Model CMR - Capacitor

We’ve taken the science behind Audio performance very seriously for over 25 years. During that time we’ve carefully researched, tested and verified the performance of our products, with leading Universities and respected audio industry figures, only launching new products when we are able to contribute tangible benefits. It is over 8 years since we introduced the highly regarded MR and ESA lines and improving on something that is already exceptional has taken time. Claritycap’s unique CopperConnect technology addresses a hitherto under explored area of audio capacitor performance. Dielectric, electrode and lead wire materials have all been extensively optimised over the years. Connection of capacitor electrodes to the leads has always relied on thermal arc spray of tin-zinc, which results in hundreds of thousands of oxidised grain boundaries introducing; distortion and phase shifts at boundary crossings and increasing propagation impedance with diameter.

Model CSA - Capacitor

We’ve taken the science behind Audio performance very seriously for over 25 years. During that time we’ve carefully researched, tested and verified the performance of our products, with leading Universities and respected audio industry figures, only launching new products when we are able to contribute tangible benefits. It is over 8 years since we introduced the highly regarded MR and ESA lines and improving on something that is already exceptional has taken time. Claritycap’s unique CopperConnect technology addresses a hitherto under explored area of audio capacitor performance. Dielectric, electrode and lead wire materials have all been extensively optimised over the years. Connection of capacitor electrodes to the leads has always relied on thermal arc spray of tin-zinc, which results in hundreds of thousands of oxidised grain boundaries introducing; distortion and phase shifts at boundary crossings and increasing propagation impedance with diameter.

Model TC - Capacitors

The TC range has been developed give Valve Amplifier designs a new level of responsiveness. Manufactured from polypropylene film, precisely metallised with a unique pattern that greatly enhances self healing, these capacitors offer a dramatic performance improvement over electrolytic types. The TC capacitor’s equivalent series resistance (ESR) and inductance are a fraction of that of an electrolytic, and therefore instantly deliver all their power precisely when it is needed. The dry construction additionally ensures that the performance is retained through out the expected lifetime of the amplifier. In electrolytic capacitors evaporation of the electrolyte reduces capacitance and increases ESR dramatically during the lifetime leading to performance degradation. In professional equipment, frequently shipped in unpressurised aircraft holds, this process is accelerated.