ClearSign Combustion Corporation products

ECC - Refinery Heaters

Because they are at the front end of the most processes in refineries and petrochemical processing facilities, optimal functioning of heaters is essential to ensure adequate production. Heater designs come in a variety of configurations depending on the process and engineering company supplying them. A common configuration is the vertical-cylindrical, up-fired system, employing multiple burners, which are installed on the furnace floor in a circular pattern. The design of these heaters must meet American Petroleum Institute guidelines which stipulate flame length must not exceed 2/3 the height of the furnace.

ECC - High Pressure Flaring Systems

All refineries and petrochemical plants have flares as a safety device. During plant start-up, or when an unexpected situation arises causing a buildup of pressurized hydrocarbon gases, the excess gas is vented through a pipe to a centralized location on the refinery grounds. There are many such sources of high-pressure gas in a plant, and for some plants the flares are gathered into a central location in a matrix of flares the size, on average, of one-to-three football fields. The terminus of each pipe rises approximately 6’ – 12’ from the ground. At the top of each pipe is a nozzle in the shape of a spider.

ECC - Ethylene Cracking Heaters

Ethylene is an important chemical widely used in the production of plastics for products such as PVC, packaging, and window frames, among others. The product is obtained by the pyrolysis of naphtha, ethane or propane. Currently there are 45 ethylene plants in the United States, 90% of which use gaseous feedstock. Due to expanded world demand, it has also experienced rapid growth.

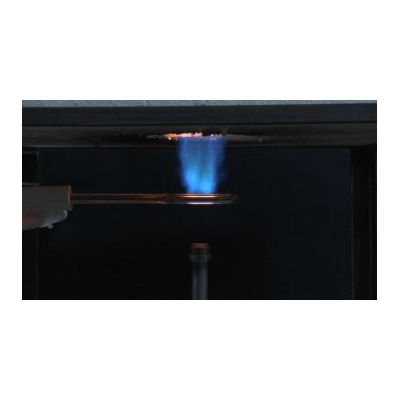

ClearSign - Model ECC - Electrodynamic Combustion Control System

Electrically charged molecules, or ions, are a natural product of the combustion process. ClearSign’s Electrodynamic Combustion Control technology introduces computer-controlled electric fields to manipulate the movement of these ions and precisely control flame shape and the transfer of heat to, through, or away from a surface.

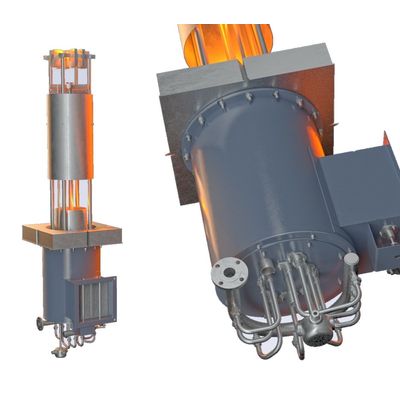

ClearSign Core - Process Burner Technology

Finally, a disruptive technology for new heaters and retrofit applications. Ultra Low NOx <5ppm: Cutting edge technology capable of meeting sub 5 ppm NOx guarantees in fielded applications. No Flame Impingement: Due to the arrangement of the burner and its combustion surfaces, flame dimensions are significantly reduced, making the burner suitable for retrofits in existing heaters that do not meet current API guidelines. Increase Heater Duty: Due to the burner arrangement, a conventional burner tile is not required, allowing the burner to increase fired capacity without the need to change existing cutouts in the furnace floor. This allows for quicker and less expensive retrofit / burner changeouts.

ClearSign Core - Boiler Burner Technology

Complete systems and retrofits available. Ultra Low NOx less than 2.5ppm: Premixed combustion, entrainment of spent flue gases coupled with increased heat loss from a high emissivity ceramic tile enable NOx levels to unprecedented levels never seen in the industry – all without the use of reagents, catalysis and/or high excess air conditions.

ClearSign - Firetube Boiler

A firetube boiler is a type of boiler in which hot gases pass from a combustion zone through one or many tubes running through a sealed container of water. The heat from the gases is transferred through the walls of the tubes by thermal conduction, heating the water and creating steam. Such boilers can be further classified as single pass, two, three or even four pass to denote the number of loops or passes the flue gases make prior to exiting via the stack.

ClearSign Core - Flare Technology

Complete systems and retrofits available. 99.99+% DRE: Achieve field verified and class leading destruction efficiency with guarantees up to 99.99% DRE. Eliminates VOC`s: Significantly reduce hydrocarbon slip and reduce the emissions footprint of your site.