Concentrating Systems Ltd. products

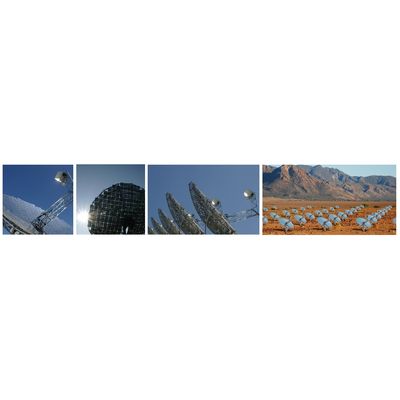

Concentrating Systems - CSP Dish Stirling Parabolic Concentrator

CSP plants of this type are designed for combined production of electrical and thermal energy. Parabolic concentrator with mirror surface reflects solar radiation to the focal point where is the PCU - power conversion unit (aggregate).

Concentrating Systems - Solar Concentrator

Solar concentrator is a primary solar component of Dish Stirling technology. Prefabricated steel zinc coated parabolic concentrator delivers the sun’s fuel into the focal point where PCU with Stirling engine’s receiver is placed. The concentrator’s area is 57m2. The parabolic concentrator reflects the incoming solar radiation (DNI) through glass mirrors onto a cavity receiver which is located at the concentrator’s focal point. Special proved silver coating glass mirrors reflect more than 94% of the sunlight and mirrors can be easy cleaned. The reflective solar radiation is absorbed by the heat exchanger receiver and thus heats the engine’s working gas Helium. In order to keep constantly the reflected radiation into the focal point during the day, double sun-tracking systems aim the solar concentrator continuously in two axes direct into the sun.

Concentrating Systems - Power Conversion Unit

PCU 35 called aggregate includes the Stirling engine with generator and an external heat exchanger – receiver. The thermal receiver is a set of thin tubes with a working gas (Helium). The thermal receiver is the interface for heat transfer from concentrating reflected radiation from solar concentrator (dish) into the hot upper side of Stirling engine. The receiver which is placed on a cavity of PCU absorbs the incoming concentrated thermal energy (700°C – 800°C). Absorbed heat energy in working gas (~650°C) is transferred into mechanical energy in expansion cylinder. Installed crank drive provides rotating driving moment (1500 RPM) for generator which generates clean electricity (400 V, 50Hz, 3 phases). Maximum operating RPM are 1800 RPM (60 Hz).

Concentrating Systems - Stirling Engine

The heat Stirling engine (SB-Tedom V-183) is the most efficient thermodynamic cycle and it is a crucial device which converts heat energy into mechanical energy like combustion engines. Our Stirling engine is designed as a single-action α modification with closed-cycle double-cylinder reciprocating engine. The work cycle occurs only on one side of the pistons. This is quite a simple design that brings an acceptable production cost. The engine`s displacement is 183 cm3. Electrical output is 2 - 10kWe with measured engine efficiency 15% - 25%. Optional thermal output is 9 - 25kWh. The gaseous working fluid is the inert gas Helium and maximum mean pressure is 15 MPa.