- Home

- Companies

- Corebon AB

- Products

Corebon AB products

Corebon - Model CorePower - Induction Heating Systems

Corebon specializes in advanced induction heating systems, bridging the gap in composite manufacturing with innovative CorePower technology. The CorePower systems provide rapid and precise temperature control, significantly reducing energy consumption and cycle times. This makes them ideal for exploring new product lines and materials. Designed for versatility, these systems accommodate a range of applications, offering modular configurations from compact units for welding to larger ones for pressing applications. The desktop variants are user-friendly, advantageous for smaller operations and R&D projects. For larger-scale applications, multiple modules can be seamlessly integrated and controlled via HMI, ensuring streamlined operations. CorePower's adaptability enables integration with existing production systems, enhancing efficiency. Advanced features such as MultiLoad and DualStation optimize equipment utilization, making it an ideal solution for efficient consecutive heating processes across various tool sizes.Corebon - Induction Heating Technology for Composites Manufacturing

Corebon AB offers a cutting-edge induction heating solution designed to revolutionize the composites manufacturing process. By integrating induction heating technology, Corebon enables a significant reduction in both unit and operational costs while unlocking the potential for innovative development and expansion in composite production. The technology offers energy efficiency improvements, achieving energy savings of 50-80% based on the specific application. This reduction is complemented by considerable decreases in cycle times, up to 80% shorter, permitting faster production and increased output. Custom-built inductors, tailored to specific applications, provide uniform or controllable heating and can include features like active cooling. These improvements create a pathway for significantly enhanced productivity and profitability in composite manufacturing.

Corebon - Induction Heated Solid Tools

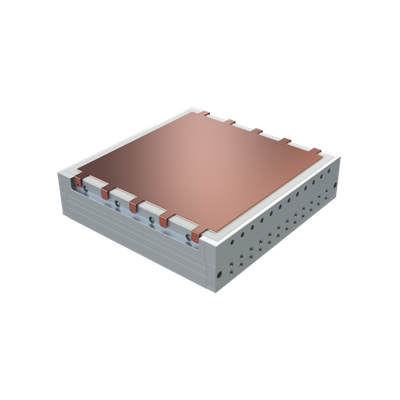

Corebon specializes in designing induction heated solid tools, primarily used in compression and resin transfer molding. These tools, typically made from aluminum or steel, are engineered for optimizing the heat conduction and cooling channel placement to enable rapid heating and cooling cycles. Corebon’s solutions achieve significant energy savings compared to traditional systems. These solid tools are suitable for processing common thermoset composites and are also adept for high-temperature consolidation and processing of thermoplastics. Corebon’s expertise extends to customized solutions upon request. Additionally, for existing solid tools, the company offers stand-alone induction heaters with customizable dimensions and heating rates, catering to diverse industrial needs.Corebon - Model CorePlate BlankXpert - Cutting-edge Temperature-Cycled Plate

Engineered for aerospace applications, CorePlate BlankXpert is a cutting-edge temperature-cycled plate designed for high-performance thermoplastic composite processing. With exceptional temperature uniformity in both heating and cooling ramps, this solution enables the production of flat or tailored laminates in single- or double-sided configurations.