- Home

- Companies

- DAVI - Promau Group

- Products

DAVI - Promau Group products

Plate Rolls - 4-Roll Plate Rolling Machines

DAVI - Model MCB - 4-roll Plate Rolling Machine

Introducing Davi's 4-roll plate rolling machine, a state-of-the-art technology that excels in repeatability, productivity, and ease of use. This advanced machine features a bottom roll that clamps the plate, guaranteeing precise control throughout the forming process. The side rolls, powered by Davi's planetary guides technology, provide exceptional bending force, achieving the tightest diameters in the market. The patented Servo-Tronic© system ensures parallelism of the rolls at all times, even in the event of electronics failure. With its compact and closed frame, customizable options, enhanced operability, and reduced maintenance requirements, Davi's 4-roll machine is a top choice for mass production and various industrial sectors.

Plate Rolls - 3-Roll Plate Rolling Machines

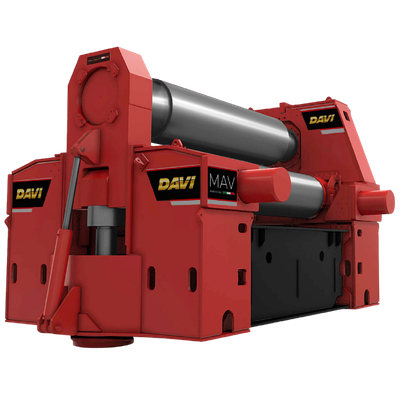

DAVI - Model MAV - 3-Roll Variable Axis Plate Rolling Machine

The Davi 3-roll variable-axis plate rolling machine is a flexible and accurate tool for plate bending. It features motorized rolls, precise positioning, and a sturdy frame for enhanced performance. The tilting rolls enable precise cone bending, while mechanical and hydraulic symmetry ensure improved tolerances and load distribution. With the patented Servo-Tronic system, rolls parallelism is maintained, and the multi-gearbox configuration enhances operability and maintenance. Davi machines are reliable and efficient for plate bending applications.

DAVI - Model MCO - 3 Roll Double Pinch

The most common design in the industry, with the top roll fixed, and the two side rolls that move up and down to pre-bend the edges, and to roll the plates. The most inexpensive roll for plates from 15-20 mm (5/8 – 3/4 inch) thickness, up to 80-100 mm (3 – 4 Inch), and more, it is recommended for limited production volumes.

Wind Energy Rolling Solutions

DAVI - Wind Tower Bending Machine

`High Productivity Package` for Wind Tower And Off-Shore Foundations; The range of plate thicknesses used to manufacture the towers and foundations for the off-shore wind industry is increased significantly, compared to the on-shore towers, reaching over 140 mm (5.5”) for the foundations and 100 mm (4”) for the towers. To contain costs and ensure competitiveness, all phases of construction of these steel structures are carefully engineered, by defining all the parameters that must be considered in the manufacturing process. Davi has responded in the past several years to the need for accuracy and high productivity of the wind industry, by engineering the Wind Tower bending machine HIGH PRODUCTIVITY PACKAGE, initially a dedicated system to produce on-shore towers and then its natural evolution for foundations and offshore structures.

DAVI Monopiles - Fixed-Bottom Foundations

Monopiles are foundation structures that typically have a diameter ranging from 7 to 15 metres (23’ to 50’); they are made of steel, using plate up to 4 or 4,5 metres (13’ or 15’) width and thicknesses varying between 50 and 170 millimetres (2" to 7"). Monopiles sections are cylindrical and conical in shape. Their maximum length can reach between 80 and 120 metres (262’ and 394’); they weigh between 3,000 and 4,000 tons. Monopiles are designed to be driven into the seabed and provide support for wind turbine towers. They are used in water depths ranging from 50 to 60 metres (164’ to 196’). The angle of conicity, which is the tapering of the conical part of the structure, varies between 10 and 16 degrees.