Delta T Thermal Solutions LLC products

Delta T Thermal - Model PLATECOIL - Heat Exchangers

PLATECOIL® Heat Exchangers combine flexibility and functionality to deliver more efficient, economical and uniform heating and cooling to any application. Customers worldwide improve performance with panels bent, rolled, or otherwise formed into wide-ranging configurations. These highly versatile heat exchangers adhere to the highest standards for design, manufacture, and testing in the industry. Delta T Thermal Solutions PLATECOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

Delta T Thermal - Model MAXCHANGER - Welded Plate Heat Exchanger

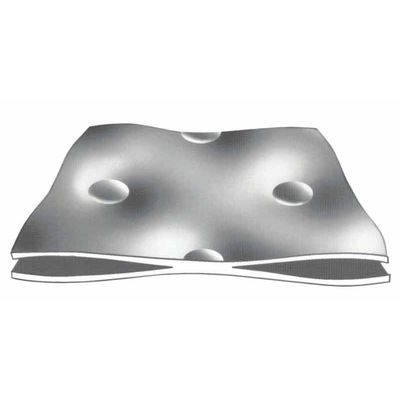

The MAXCHANGER all-welded plate heat exchanger offers higher performance, in less space, at a lower cost. The unique geometry of the patented MAXCHANGER’s variable interspaces produce extremely high “U” values. Channels formed between the specially dimpled, welded plates direct the two heat transfer media counter currently through alternate paths for maximum efficiency, immediate thermal response and a close temperature approach capability of less than 1°C (2°F).

Delta T Thermal - Model ECONOCOIL - Light-Duty Plate-Type Heat Exchanger

Delta T Thermal Solutions ECONOCOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

Delta T Thermal - Turnkey Solutions

As part of the Sharp Iron Group, our team of design and applications engineers have direct access to a deep well of manufacturing capabilities to support your project. From small, machined components to complex fabrications and assemblies, Sharp Iron Group has successfully supported the unique needs of companies in the energy, water, mining, medical, electrical, aerospace, marine, semiconductor, and heat transfer industries for over 40 years. Sharp Iron Group maintains a broad spectrum of manufacturing capabilities across two business units in Wichita Falls, TX, totaling almost 200,000 square feet and over 100 professional craftspeople. Quality certifications include ASME (Section VIII, Div 1, U and R stamps), ISO-9001, and AS-9100. In addition, the Quality staff maintains NACE (Level II) and CWI certifications. Sharp Iron Group is ITAR registered, and DD2345 certified.