Despatch Industries (ITW) products

Industrial Furnace

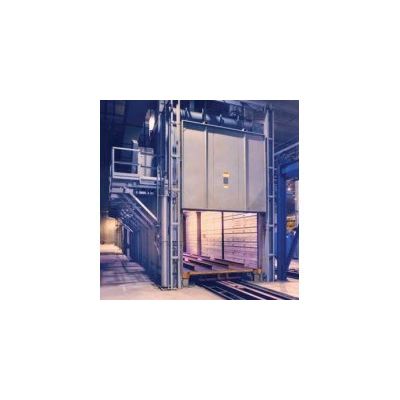

Despatch - Car Bottom Furnace

The Despatch car bottom furnace is available in gas or electric versions with temperatures up to 1800°F (1000°C) and a +/- 5°F temperature uniformity after stabilization. The car bottom furnace is designed for easy transport of heavy loads and comes equipped with pneumatically actuated car seals and electrically actuated vertical lift doors incorporating clamps to ensure a tight seal.The furnace body is constructed with heavy gauge steel reinforced external shell. Eight inches of multi-layered ceramic board insulation insulate the furnace walls, ceiling and door, minimizing heat losses. The ceramic board is preshrunk to allow for tight fitted joint construction. The base of the furnace is constructed of segmented structural steel components and fire brick insulation. The furnace has multi-zone high velocity, horizontal airflow with reversing flow and a forced air cooling capability to provide plunge cooling or maintain lower control settings.

Despatch - Continuous Infrared Furnace

The Despatch In-line Infrared Furnace incorporates advanced infrared thermal technology that provides extremely tight temperature uniformity. Air is passively preheated as it enters the chamber and lamps on top and bottom, along with edge heaters, effectively transfer heat up to 1000 °C (1832 °F) to the product.Our infrared systems consist of a load station, multi-zone infrared heating and cooling sections and an unload station. Despatch conveyorized infrared furnaces include a patented drop down chamber for easy maintenance, the ability to control atmosphere to reduce oxidation and closed loop temperature controls for tight uniformity. Systems are controlled by an industrial PC and contain a custom Despatch furnace control application with an easy-to-use graphical user interface.

Other

Despatch - Custom Industrial Ovens

A Despatch custom product is a low-risk choice for your complex challenges. Despatch has over 100 years of proven success in partnering with customers to deliver complex thermal processing and environmental simulation solutions.We are committed to working with our customers to learn the details of their unique process in order to design and engineer a custom piece of equipment that will meet their specific requirements. When it comes to evolving an existing application or implementing a first-of-its-kind process, more global businesses choose Despatch. Our innovative designs are backed by seasoned engineering, manufacturing and project management teams with decades of experience completing projects on time, on budget and always to the satisfaction of our customers.

Solar Products

Despatch - Metallization Firing Furnace

The Worlds Best Selling Metallization Furnace. Despatch CF Series metallization furnaces are designed for high throughput, ease of maintenance and consistent process repeatability ensuring consistently high yields and superior product quality.

Industrial Ovens - Cabinet Ovens and Furnaces

Despatch - Polyimide Industrial Curing Oven

The Despatch PCO2-14™ electrically heated oven was designed to meet the specific process requirements for hard baking polyimide coatings in an inert atmosphere. This high-performance, clean process oven (ISO Class 5/Class 100 recirculated airflow) offers many unique components, including a pressure relief system, an oxygen control system and a process monitoring system which allows the oven to achieve the strict oxygen level and atmospheric requirements involved in polyimide curing.

Despatch - Catheter Annealing Oven

The Despatch PRC2-63 is designed specifically to address the unique requirements of catheter manufacturers. It’s a one-size-fits-all solution that features vertical airflow to keep cross wind from blowing tubes around, a tall configuration with a small footprint to save floor space while allowing room to hang catheters up to 80 inches long inside the chamber, and a stainless steel interior for easy cleaning. A truck and dolly system with a rack for hanging catheters is available as an option. Purchasing two trucks allows for preloading one truck while the other is in the oven to improve productivity.