- Home

- Companies

- Eco Energies

- Services

Eco Energies services

Power Quality Analysis

To ascertain electrical load utilization (separate for each electrical meter). Check on incoming main (separate for each electrical meter) - R, Y, B phase & Neutral. Detail Harmonic & transient study with recommendations. Checking face balance at different locations. Segregation of power at different locations.

Assessment of Electricity Tariff Plan

Data collection on total connected load. To check whether sanctioned load is less than the connected load. To check whether they has applied for additional load. To check whether branch has paid any penalties for excessive load.

Energy Audits

Detailed Energy Audit – Plant/Site

Assessment of boilers. Steam distribution system. Air compressors. Motors. Pumps. D G sets. Transformers. Assessment of capacitors. Cooling towers. Heat exchangers. Hvacs. Lightening system. Power quality analysis. Assessment of electricity tariff plan.

Electrical Energy Audit

Areas covered under Electrical Audit are: Electrical Distribution system (substation & feeders study). PF Improvement study. Capacitor performance. Transformer optimization. Cable sizing & loss reduction. Motor loading survey. Lighting system. Electrical heating & melting furnaces. Electric ovens.

Thermal Energy Audit

Areas covered under Thermal Audit are: Steam generation boilers. Steam audit and conversation. Steam trap survey. Condensate recovery system. Insulation survey. Energy and material balance for unit operation. Heat exchanger. Waste heat recovery system.

Major Plant Installations Audit

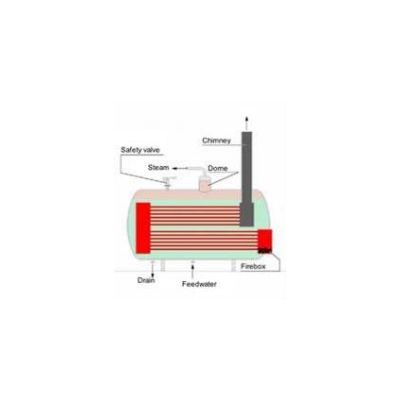

Auditing of Boilers

Performance evolution of Boilers. Feed air & Flue gas analysis. Optimization of excess combustion. Improved instrumentation for control. Improvement in operating practices. Incorporate heat recovery. Reduction of heat losses.

Auditing of Air Compressors

F.A.D. (Free Air Delivery) Test for all air compressors. Leak Test for compressed air system. Air leak points identification. Matching the demand side management with supply. 5. Proper cooling and appropriate air intake of Air Compressors.

Diesel Generator Set Auditing

Checking of ventilation arrangement for the DG unit room. Checking of loading pattern of DG Sets. Checking adequacy of capacity of DG set w.r.t to actual requirement. Checking of type of load taken on DG and evaluating its necessity. Checking noise level of DG. Physical verification of wiring of DG. Checking of effectiveness of cooling system of DG. Checking of per unit power generation w .r.t consumption.

Auditing of Transformers

Three phase power analysis (each phase voltage, current, power factor, power-Kw, kVA, kVARh etc.) of Running Load of transformer. Load test of transformer. To check adequacy of transformer w.r.t. required capacity. To check protection provided at the location of transformer. To check grounding/earthing of transformer.

Assessment of Capacitors

Testing of present capacitor banks. Locating capacitor banks at appropriate location. Requirement for any new capacitor bank. Installation of capacitors on motors having inductive load.