The Tank Commander™ Vapor Management System (VMS) provides you with the ability to directly capture 100% of your tank vapor while simultaneously eliminate tank venting emissions, maximizing the value of your oil and gas producing assets. Venting and flaring from tank batteries have emerged as the most significant source of well site emissions today, which means controlling tank battery emissions represent the greatest opportunity for making environmental performance gains. The Tank Commander VMS is our latest innovation, combining our proven ZerO2 technology with automated system for controlling oil and produced water storage tank pressures – allowing you to both sell valuable high-BTU tank vapor gas and eliminate venting emissions.

EcoVapor Recovery Systems products

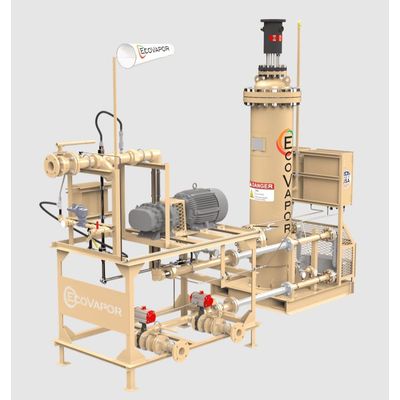

Model ZerO2 - Eliminate Routine Flaring

The ZerO2™ vapor recovery system enables you to directly capture 100% of your tank vapor, eliminating the need for routine flaring while generating more revenue. Our reliable, patented technology advances vapor recovery performance by eliminating oxygen from tank vapor gas from multiple sources – oil storage tanks, produced water storage tanks and truck loadouts – allowing you to sell valuable high-BTU gas instead of flaring it. ZerO2 can also be used in gas blanketing applications to remove oxygen and help you mitigate ignition risk in storage tanks.

Biogas Purification - Agricultural Biogas Purification

ZerO2 – Oxygen Removal from Biogas (deoxo)

The ZerO2 oxygen removal (deoxo) solution gets you one step closer to capturing the RNG opportunity. Our reliable, patented technology is an environmentally safe deoxo solution for eliminating oxygen from biogas streams, including dairy and swine farms as well as Landfill Gas (LFG) operations. Purifying biogas from oxygen is a critical step in upgrading raw biogas to Renewable Natural Gas (RNG). With several models for different gas processing capacities combined with its modular design, ZerO2 is the most flexible and scalable catalytic deoxo solution for biogas projects of all sizes.

H2S Treating for Biogas Operations

The Sulfur Sentinel H2S solution purifies biogas and landfill gas feedstocks of H2S, getting you one step closer to capturing the RNG opportunity. Sulfur Sentinel™ is an all-in-one solution for cost-effectively purifying biogas and landfill gas (LFG) feedstocks of H2S. It uses a simple but highly effective dry iron oxide scavenger to safely remove hydrogen sulfide from the gas stream. This eliminates the complex equipment and scale inhibitors needed when using liquid chemicals. The spent iron oxide is easily and safely vacuumed from the vessel and disposed of in a local landfill as a non-hazardous waste.

Biogas Purification

Landfill Biogas Purification

Technologies to Upgrade Your Landfill Biogas and Meet Pipeline Specifications. EcoVapor’s catalytic deoxo (oxygen removal for biogas upgrading) and H2S treating solutions remove contaminants from your Landfill gas stream, specifically by eliminating oxygen and H2S using sustainable technologies without generating harmful byproducts. This helps you purify your biogas stream to meet pipeline specifications and is a critical step towards capitalizing on valuable Renewable Natural Gas (RNG). ZerO2™ is modular and facilitates a flexible approach, making it easy to scale up or down, as your landfill gas feedstock volumes and budget permit.