ENEPAQ products

Battery Management System (BMS)

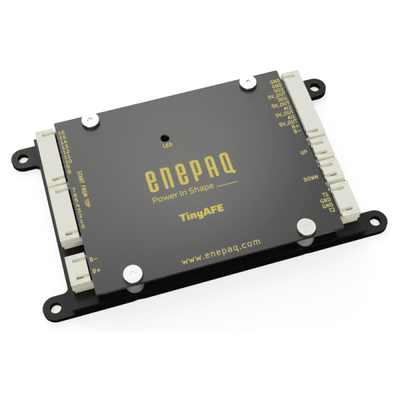

ENEPAQ TinyAFE - Battery Monitoring System

Battery Monitoring System – TinyAFE up to 1000V Slave Board Digital Analog-Front-End Battery Monitoring for Custom High Voltage Applications.

ENEPAQ TinyBMS - Customizable Battery Management System

Customizable Battery Management System: Tiny BMS s516 (30A Peak Discharge); Battery Management System (BMS) 30A – The Tiny BMS is an essential component for every Lithium battery. Enepaq Tiny BMS supports lithium batteries of any chemistry and up to 60 V nominal. Battery capacity from sub-1 Ah to 655 Ah can be managed easily. Tiny BMS measures individual voltages of parallel cell groups and manages the switching of load and charger. During charging, cells are balanced by bleeding off higher cells to accomplish full balance and maintain good health of the battery pack. State-of-Charge is calculated as well, and is available via communication bus to be displayed for the user.

Battery Modules

ENEPAQ - Sony/Murata Li-ion Battery Module

Battery Module from Enepaq combine the best of two worlds – Low Weight, High Power, Quality, Safety and Ease of Use. Enepaq Battery Modules are a unique blend of latest battery technology, safety and ease of use. Each Battery Module is made of several 3.6V 18650 Li-ion cells connected in parallel. Several such blocks may be connected in parallel and series to form high voltage Battery Packs of various shapes and sizes.

ENEPAQ - Sony/Murata Li-ion Battery Module

Enepaq Battery Modules are a unique blend of latest battery technology, safety and ease of use. Each Battery Module is made of several 3.6V 18650 Li-ion cells connected in parallel. Several such blocks may be connected in parallel and series to form high voltage Battery Packs of various shapes and sizes. Even though a cylinder may seem as not effective use of space at a first glance, the internal conductors are very tightly rolled and often offer higher energy density per volume and weight than competition, even per whole pack, counting in the air gaps among cylinders. No need for compression plates gives yet another way to save some space and weight. Resulting air gaps also offer an opportunity of easy and effective thermal management solution, either by liquid or air.