- Home

- Companies

- EnviroPro, Inc.

- Products

EnviroPro, Inc. products

Flare Systems - Steam Flares

EnviroPro - IS3 Steam Flare Tip

Internal steam flare tips use inner steam to inspirate more air into the combustion zone. The steam manifold and nozzles are located in a lower position on the flare tip. The steam/air mixture is directed up through the inside of the flare tip to exit and mix with waste gas for burning. This approach significantly reduces the amount of steam required to inject the same amount of air using upper steam tips. Relocating the manifold to a lower position on the flare tip allows a muffler to be installed, significantly reducing steam noise.

EnviroPro - Upper Steam

Sometimes referred to as steam assisted pipe flares, upper steam flares have a steam manifold near the top of the flare tip. The manifold distributes steam to nozzles surrounding the outside diameter of the flare tip, just above the flare tip exit. Steam injected into the combustion zone pulls air in along with it. This additional combustion air increases the amount of waste that can be burned for smokeless operation. Upper steam flare tips are often used where customers have lower smokeless capacity requirements or where less demanding waste gasses are being treated, Upper Steam Assist flares incorporate a high-stability pilot and a flame retention system. With a high efficiency, low noise steam injection ring, the flare tip provides smokeless burning with quieter operation than traditional steam injection systems.

Flare Systems - Ground Flares

EnviroPro - Multipoint Ground Flares

Multipoint ground flares are 100% smokeless flare systems that break up the gas loading into separate stages and burners. As pressure in the flare header increases and decreases, a PLC opens and closes valves to bring stages online or take them off. A proper velocity is maintained to sufficiently pull air into the combustion zone and burn 100% smokeless. If the first stage is open to the process, assist steam or air would be needed for smokeless operation. The flare field is surrounded by a fence that hides much of the flame from view and protects the surrounding area from radiation. All staging valves and controls are located outside the fence and are accessible for maintenance even when the flare is online.

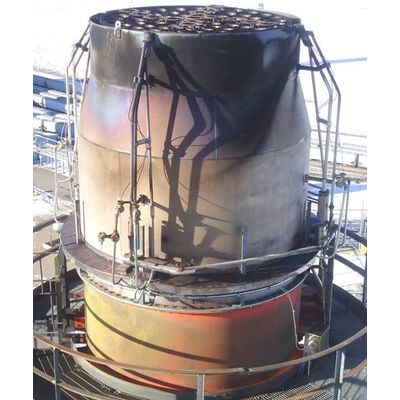

EnviroPro - Totally Enclosed Ground Flares

Totally enclosed ground flares have stages like multipoint ground flares and use flare gas pressure to operate 100% smokelessly. Instead of a fence, waste gasses are burned inside a refractory lined combustor. Totally enclosed ground flares burn vapors with a high destruction efficiency and emit no noise or light pollution. Because combustion occurs inside an enclosure, there’s a practical limit to the amount of vapors that can be flared. Common applications for totally enclosed ground flares include marine vapor combustors, truck loading terminals, and tank vent combustors. Under certain circumstances, low pressure vapors can be flared smokelessly in a totally enclosed ground flare without the use of assist air or steam. Talk to the EnviroPro flare experts to see if your application fits.