- Home

- Companies

- ETIA S.A.S.

- Products

ETIA S.A.S. products

Model Spirajoule - Electrically Heated Screw Conveyor

Spirajoule® is a dedicated equipment for a continuous thermal treatment in temperatures up to 850 degree C, basing on a hollow shaft screw conveyor heated by a low voltage current. The screw is made from electrically conductive material and is connected to an electricity power supply. Electricity is conveyed from the power supply by the specially design components located at both sides of the screw. The passage of electronic current through the conductor (screw) generates heat, which is as a result of Joule heating (also known as Ohmic heating or resistive heating).

ETIA Spirajoule - Electrically Heated Screw Conveyor

Spirajoule is eletrically heated screw conveyor proven for 20 years in industrial operation. Technology allows perfectly controllable, thermal processing of organics and minerals.

ETIA - Model UPK - Screw Heat Exchanger

Our UPK products are indirect and continous continuous cooling or heating equipment based on screw heat exchanger. It is well suitable for bulks, powders, granulates, pasty or muddy products. Its cooling and heating function is accomplished through chilled water, steam or other thermal fluid passage into the screw and double jacket.

Efficient Cooling and Heating

Our UPK® products are indirect and continous continuous cooling or heating equipment based on screw heat exchanger. It is well suitable for bulks, powders, granulates, pasty or muddy products. Its cooling and heating function is accomplished through chilled water, steam or other thermal fluid passage into the screw and double jacket. Construction of our screw heat exchanger also allows the control of the atmosphere conditions above the product: wet extraction, dried air injection, steam injection and many other. Paddles fixed to the screw allow a perfect homogeneous treatment, mixing, conveying, and cooling or heating transfer.

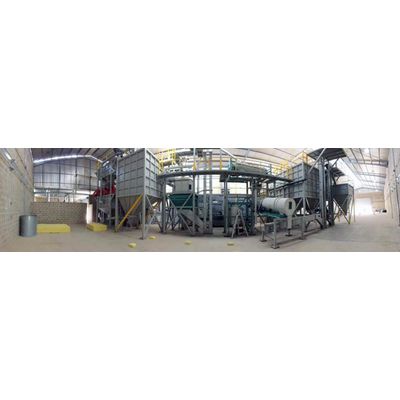

Termobio - High-Efficiency Biomass Screw Dryer

Termobio is high-efficiency biomass dryer developed and patented by ETIA. Its construction bases on screw conveyor equipped with brushes that ensure the good material transportation along the dryer. The solution is designed to dry biomass from up to 50% down to less 5% and adapted to a variety of wood sawdust, straw, pellets as well as biomass chips. The unique construction of the dryer ensures high heat transfer coefficient, low investment, and little operational costs.

Model Torresak - Biochar Packaging Solution

Belt-o-Matic - Belt Dryer

We offer continuous flow conveyor system for drying, roasting, and or cooling that offers many auxiliary options for a wide selection of products and applications.

Equipment

Beltomatic - Continuous Belt Dryer

ETIA is a partner of BNW industries which offers a belt dryer with stainless belt for thermal treatment (cooling or heating) of wide range of products at small or large particle size.

Pyrolysis Products

Syngas - Synthesis Gas

Syngas, also called a synthesis gas, is a mix of molecules containing hydrogen, methane, carbon monoxide, carbon dioxide, water vapours, as well as other hydrocarbons and condensable compounds. It is a main product of gasification and majority product of high temperature pyrolysis carried on any biomass, residues and waste. When produced in pyrolysis, it is created by the vaporisation of volatile compounds from the raw material thanks to the heat, which induces a set of complex reactions.

ETIA - Pyrolysis Oil

Pyrolysis oil is a liquid substance obtained in pyrolysis process and subsequent cooling. It is a complex blends of molecules usually consisting more than 200 different compounds resulting from the depolymerisation of products treated in pyrolysis.