- Home

- Companies

- FCT Systeme GmbH

- Products

FCT Systeme GmbH products

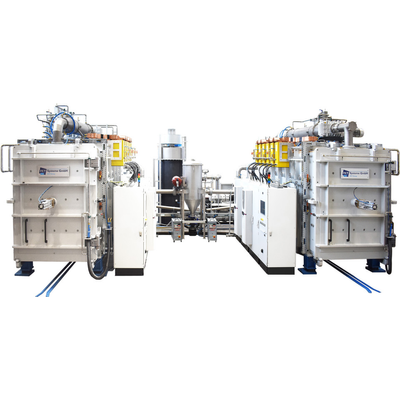

High-Temperature Vacuum Sintering Furnace

FCT - Resistance Heated High-Temperature Vacuum Sintering Furnace

Due to their induction heating, induction-heated high-temperature vacuum sintering furnaces are used especially for large furnace volumes and application temperatures of up to 2500 °C. As a result of the uniform energy output, the inductively heated graphite susceptor achieves very good temperature uniformity even at high temperatures of 2500 °C and more. The higher investment cost compared to resistance heated furnaces is offset by a much longer service life.

FCT - Inductive Heated High-Temperature Vacuum Sintering Furnace

Due to their induction heating, induction-heated high-temperature vacuum sintering furnaces are used especially for large furnace volumes and application temperatures of up to 2500 °C. As a result of the uniform energy output, the inductively heated graphite susceptor achieves very good temperature uniformity even at high temperatures of 2500 °C and more. The higher investment cost compared to resistance heated furnaces is offset by a much longer service life.

FCT - Resistance Heated High-Temperature Vacuum Sintering Furnace

These horizontal, resistance-heated sintering systems are used in many areas of application, as they can be operated both in a vacuum and in an inert atmosphere. The main area of application is the debinding and subsequent sintering of ceramics, composite materials or powder metallurgical components.

FCT - Resistance Heated High-Temperature Vacuum Sintering Furnace

These vertical, resistance-heated sintering systems are used in many areas of application, as they can be operated both in a vacuum and in an inert atmosphere. The main area of application is the debinding and subsequent sintering of ceramics, composite materials or powder metallurgical components. They are used in particular for high-temperature processes such as carbonization, recrystallization, silicon infiltration, nitriding (formation of Si3N4), vacuum sintering or metallization. Optionally, these systems can be equipped with a debinding/dewaxing system as a combined process. Rapid cooling is also available to significantly reduce cooling times.

Gas Pressure Sintering Plants (GPS)

FCT - Resistance Heated High-Temperature Pressure Sintering Furnace with Integrated Hot Pressing Function

In addition to conventional gas pressure sintering, also known as Sinter-HIP, this furnace type is particularly characterized by its high flexibility and the ability to combine it with other sintering methods. Sintering under vacuum and partial pressure, as well as gas pressure sintering up to 100 bar, can be implemented—along with combinations of all these atmospheres with uniaxial hot pressing.