Fluid Equipment Development Company (FEDCO) products

Turbochargers

FEDCO - Hydraulic Energy Management Integration Turbocharger

The HEMI is a motor assisted HPB. The HEMI provides control of feed and brine flows in SWRO while the primary feed pump runs at constant speed and pressure. What the HEMI does: Provides exceptional energy recovery efficiency. Eliminates the VFD on the High-Pressure Pump. Computational Fluid Dynamics analysis optimizes every HP-HEMI for peak efficiency at your duty point conditions. Industry-leading three (3) year limited warranty. Super Duplex SS 2507 standard MOC. Complete ERD package – user provides just standard control signals, power, and process piping.

Low Pressure Energy Recovery

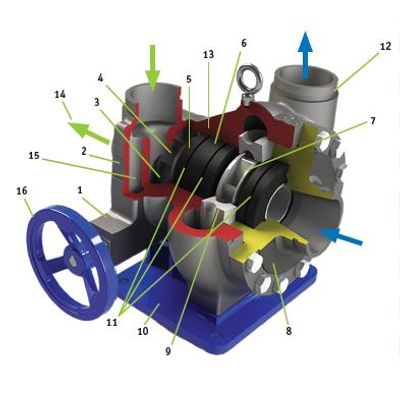

FEDCO - Energy Recovery Motorized Turbocharger

The LPH series pumps integrate pump and turbine modules for a motorized turbocharger energy recovery device and interstage booster. The LPH is revolutionizing pumping and energy recovery in brackish water reverse osmosis (BWRO). The rapid acceptance is driven by simple economics – an ERD is only worth using if the cost of saved energy can offset the capital and installation cost of the ERD (a quick return on investment or ROI). The unique modular construction of the FEDCO LP product line allows a few components to be configured in dozens of ways to achieve the performance requirements of a wide range of BWRO systems without high capital and installation costs. Maintenance costs are likewise reduced as a maintenance spare and procedures are minimized for large installations.

FEDCO - Energy Recovery Turbine Generator

The LPD turbine generator uses low-pressure brine hydraulic energy to produce electrical energy. The LPD turbine generator Energy Recovery Device uses brine hydraulic energy to drive a standard induction motor that acts as a generator to produce electrical energy. Integrated into the unit is a regenerative VFD that regulates the LPD to achieve brine flow and pressure as required for the desired membrane operating conditions while extracting the maximum amount of electrical energy available from the brine stream. The vertically mount motor eliminates a large baseplate. The shaft alignment is assured by highly accurate machine fits of the components.