- Home

- Companies

- Fugesco inc.

- Products

Fugesco inc. products

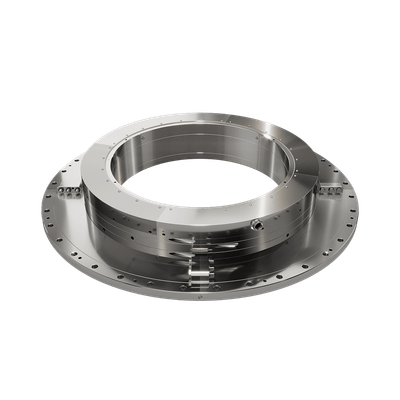

Fugesco - Radial Turbine Seal for Hydroelectric Turbines and Pumps

Radial type seals are integral to the efficient operation of hydroelectric turbines, pump-turbines, and large pumps. These seals may require two or more carbon segmented sealing rings depending on design parameters such as pressure, speed, and vacuum. Custom-designed for a wide range of equipment, these seals are straightforward to install, self-adjusting, and easy to maintain. Fugesco offers both split and non-split versions, manufactured to client specifications. A key component is the precision sleeve, mounted on the turbine shaft, which works with the carbon sealing rings to perform the essential sealing function. The sleeves, also available in split and non-split versions, are made from various materials based on service conditions. Radial seal operational limits include a maximum turbine operating pressure of 140 to 280 kPa, barrier water pressure of 20-35 kPa above turbine pressure, and water filtration to 25 microns. Optional features like splash guards, reservoirs, RTD's, wear indicators, and inflatable maintenance seals are frequently added based on client needs. Composite designs reduce the weight of seal components, generating cost savings during installation and maintenance outages.Fugesco - Axial Turbine Seal for Hydroelectric Turbines and Large Water Pumps

FUGESCO's axial type seals are engineered for use in hydroelectric turbines and large water pumps, such as those used in sewage handling, filtration, and irrigation systems. These seals are designed to withstand operational pressures of 20-70 kPa (3-10 psi) above the turbine pressure and require water filtration down to 25 microns. Capable of handling radial shaft dislocations of ± 1.3 mm (0.06 inch) and axial shaft dislocations of ± 3 - 25 mm (0.125 inch), the seals have a shaft/sleeve finish of 63 RMS. Self-aligned and balanced, these seals can endure heavy torques, pressures, and shaft movements. Typically, they consist of a base ring, cover ring, and sealing rings, with the cover ring secured to the base ring bridging the gap between the turbine shaft and the head cover. The seals use an inflatable design for easy installation, requiring no special vulcanization tools. Clean water, filtered to remove particles larger than 25 microns, is crucial for cooling and lubrication, maintaining a pressure higher than the water pressure under the seal. An assembly kit and an optional seal water control panel with a differential pressure regulator ensure optimal operation and maintenance.Fugesco - Custom Molded Dam Gates Seals

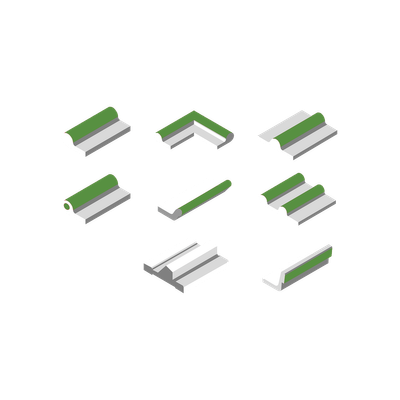

Fugesco specializes in producing elastomeric gate seals for hydraulic gates. These seals are custom-molded, ensuring high dimensional accuracy and resistance to UV light. Fugesco uses a variety of materials including SBR (styrene butadiene rubber), CR (chloroprene rubber), NR (natural rubber), as well as other elastomers such as EPDM, NBR, and fluorine. The seals can be designed according to specific customer requirements, including options for PTFE cladding. The compression molding process guarantees ease of assembly and a perfect fit, particularly in challenging areas like corners, resulting in zero leakage and enhanced durability. With over 60 years in the industry, Fugesco has developed a wide array of tooling, thereby remaining competitive in price and delivery. The company`s philosophy centers on in-house design, engineering, and manufacturing, aimed at providing solutions for the most challenging applications and special projects.