- Home

- Companies

- GAB Neumann GmbH

- Products

GAB Neumann GmbH products

Graphite Heat Exchangers

GAB-Neumann - Annular Groove Graphite Heat Exchangers

Annular groove graphite heat exchangers (interchangers) are especially adapted to the heating or cooling of ultra-corrosive liquid chemicals. This specific design allows for heat recovery between two ultra-corrosive fluids. Annular grooves are machined into impervious graphite discs to form the process and service channels. Heat is transferred by conduction through the graphite left between the process and the service channels. Annular groove graphite heat exchangers consist of a stack of graphite discs that are fused together.

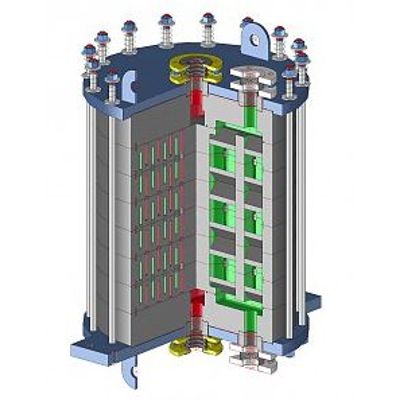

GAB-Neumann - Graphite Block Heat Exchangers

Graphite block heat exchangers are adapted to the heating, cooling, evaporation, condensation and absorption of highly corrosive liquid chemicals. This design is one of the most versatile type of impervious graphite heat exchangers. Rows of holes are drilled through graphite blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the impervious graphite left between the rows of holes which separate the mediums being used. Graphite block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

Silicon Carbide Heat Exchangers

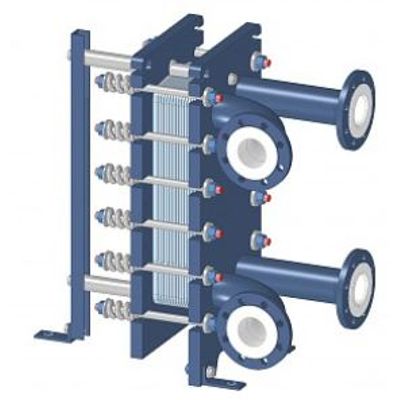

GAB-Neumann - Silicon Carbide Plate Heat Exchangers

CORRESIC® silicon carbide plate heat exchangers are adapted to the heating and cooling of highly corrosive and/or oxidizing chemicals. This design is the most compact and most efficient type of silicon carbide heat exchangers. Our CORRESIC® silicon carbide plate heat exchangers are composed of many thin, slightly separated silicon carbide plates that have very large surface areas and small fluid flow passages for heat transfer. Heat is transferred by conduction through the silicon carbide plates material. Plate exchangers work with countercurrent flows which allows low temperature differences, rapid temperature changes, and high efficiencies.

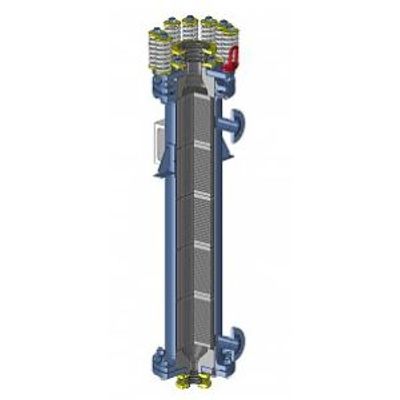

GAB-Neumann - Silicon Carbide Block Heat Exchangers

CORRESIC silicon carbide block heat exchangers are adapted to the heating, cooling, evaporation, condensation and absorption of highly corrosive and/or oxidizing chemicals. This design is one of the most versatile type of silicon carbide heat exchangers. Rows of holes are drilled through the silicon carbide blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the silicon carbide left between the rows of holes which separate the mediums being used. SiC block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

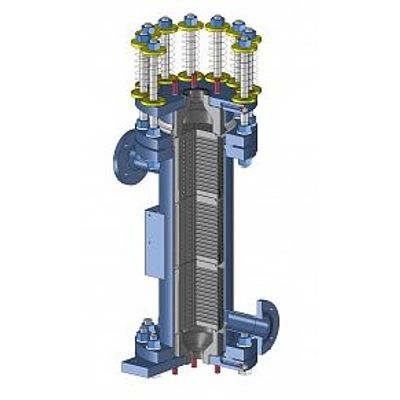

GAB-Neumann - Silicon Carbide Shell and Tube Heat Exchangers

CORRESIC Silicon carbide shell and tube heat exchangers are adapted to the cooling, condensation, heating, evaporation and absorption of highly corrosive chemicals. Silicon carbide shell and tube heat exchangers consist in a bundle of silicon carbide tubes inside a shell. One fluid runs through the tubes and another fluid flows over the tubes (through the shell). The heat is transferred by conduction through the silicon carbide tube wall, without direct contact between the fluids.